Japan-made Glass, Which Has Passed a 200,000 Cycle Bending Test, Adopted for the Motorola razr 50 and razr 60 series

- • Foldable smartphone market growing rapidly to expand eight-fold by 2028!

- • “Glass” is the key to clarity

- • NEG’s glass adopted for Motorola’s razr 50 and razr 60 series

- • Why does the glass bend and not break?

- • Glass that does not break even when hit with a hammer

- • Bending achieved by glass that is thinner than paper

- • Passing a repeated bending test of 200,000 cycles!

- • Superb flatness which underpins high-definition displays

- • Potential of Dinorex UTG™, which is made in Japan

Foldable smartphone market growing rapidly to expand eight-fold by 2028!

Generally, smartphones adopt the slate design. However, there have been signs of change in recent years. The foldable design, which was common for feature phones, have started to spread to smartphones. MM Research Institute released a projection that the shipment of foldable smartphones in Japan will increase about eight-fold to 1.81 million units by FY2028 compared to FY2023. Foldable smartphones are mainly chosen by people in their 40s or older, who were accustomed to the foldable design in the feature phone era, and young people who are interested in advanced technologies.

“Glass” is the key to clarity

The spread of foldable smartphones has been accelerated by the use of glass for the display cover. Previously, a transparent resin called polyimide (PI) was used for the display cover for foldable smartphones. Although resins are resistant to bending, they are easily scratched and cause discoloration of the screen over time, resulting in loss of screen clarity. The use of glass makes the folding section barely noticeable, realizing a clear, transparent display with the luxurious feel that is unique to glass.

Unfortunately, most display cover glass used for foldable smartphones on the market is manufactured by companies outside Japan.

NEG’s glass adopted for Motorola’s razr 50 and and razr 60 series

Motorola has released the razr 50 and razr 50 ultra, flagship foldable smartphone models, whose display cover for the main display features Dinorex UTG™, ultra-thin glass for chemical strengthening manufactured by *Nippon Electric Glass (“NEG”). With European and U.S. glass companies leading the market share, this is the first time for glass manufactured by a Japanese company to be adopted as the display cover for a foldable smartphone.

* NEG is a special glass manufacturer with a global market share of over 20% for flat panel display glass.

The razr 50 and razr 50 ultra, which are from Motorola’s razr 50 series, feature a 6.9-inch pOLED display that can be folded in two. The display is characterized by a rich color expression and high contrast. The refresh rate of the razr 50 and razr 50 ultra is 120 Hz and 165 Hz, respectively. It has also continued to be featured in the razr 60 series, which was announced in April 2025. Why was NEG’s glass chosen for the cover glass for the high-quality display of the razr 50 and razr 60 series instead of products of major overseas glass manufacturers?

Why does the glass bend and not break?

What is “chemically strengthened glass,” which underpins the technology of foldable smartphones? This section explores the unique advantages of NEG’s glass, such as the technologies and properties.

Glass that does not break even when hit with a hammer

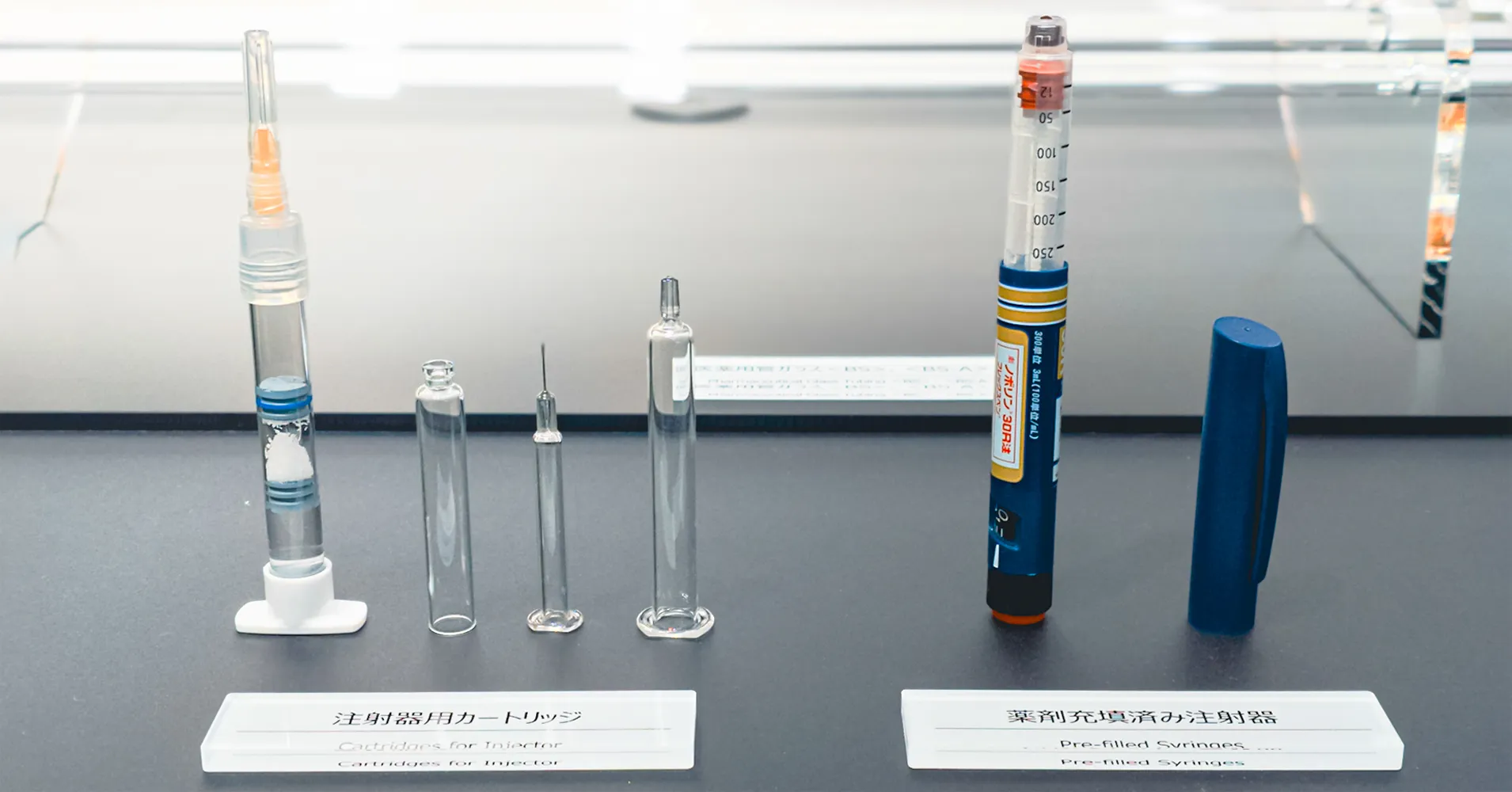

Chemically strengthened glass with a thickness of about 0.5 mm and 0.7 mm has been used as the display cover glass for smartphones. It is an important component that protects the LCD or OLED display screen from scratches and impacts.

Chemically strengthened glass refers to glass whose surface is strengthened by special chemical treatment *. The strength is five-fold or more that of ordinary glass.

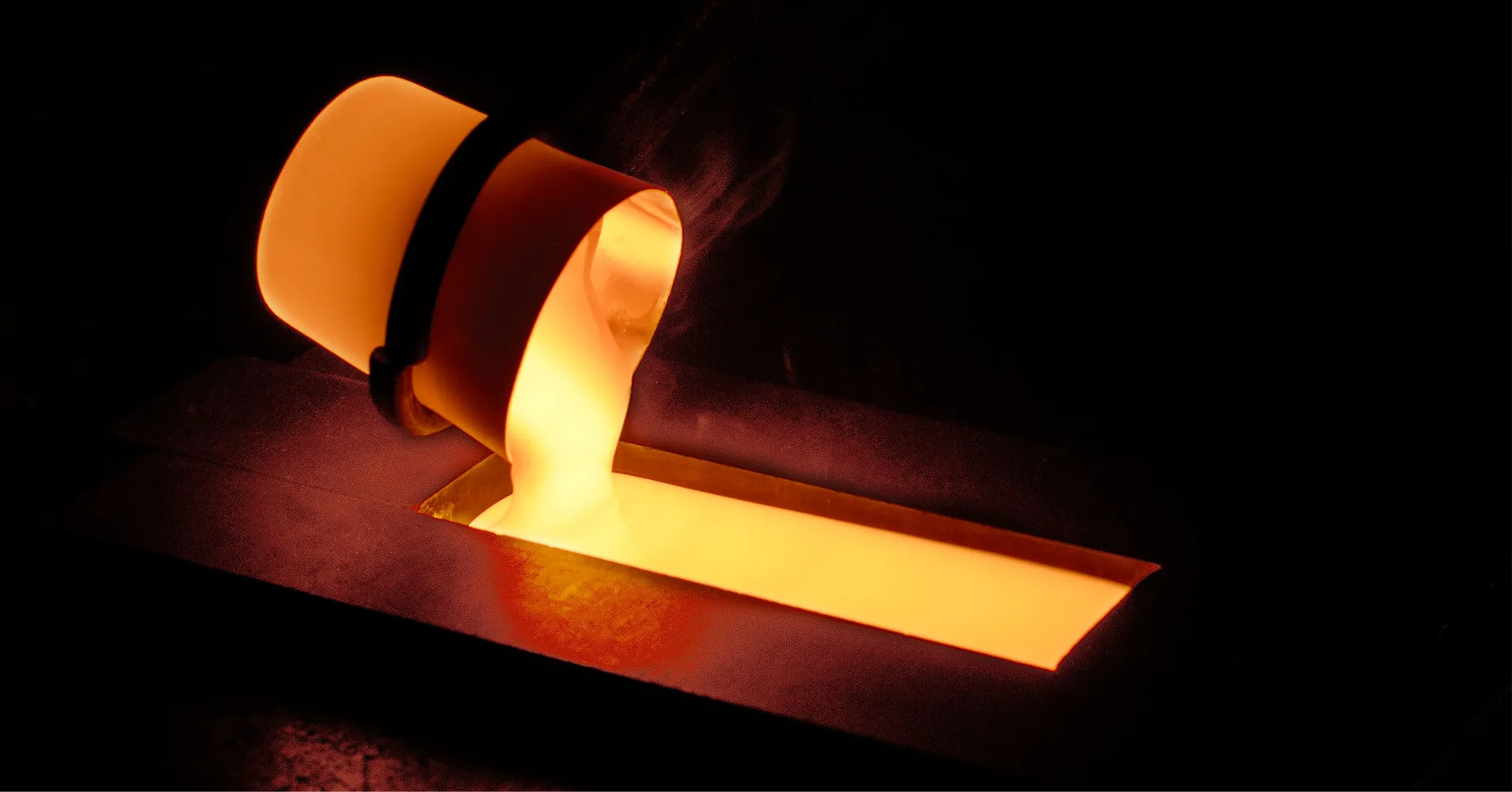

* Chemical treatment of glass for chemical strengthening

Glass containing sodium ions (Na+) is immersed in a potassium nitrate solution containing potassium ions (K+). The Na+ ions on the surface of the glass are replaced by K+ ions, which have a larger diameter in the solution. This process is known as “ion exchange.”

Even if stress due to an external impact or force to expand a crack on the glass surface (tensile stress) is applied, compressive stress is created on the surface of the glass in the opposite direction. Because the stress is offset, it becomes difficult for the crack to propagate, making the glass less likely to break.

For details, refer to the Dinorex™ product page.

Bending achieved by glass that is thinner than paper

One of the technological challenges in developing foldable smartphones was the realization of a foldable display. Previously, resins were used because conventional chemically strengthened glass broke when bent.

The property that the thinner the glass, the more resistant it becomes to bending has been known for a long time. However, there were many technological challenges to overcome to achieve practical application. NEG launched R&D on bendable ultra-thin glass, more than 20 years ago with the aim of developing products that take full advantage of this property.

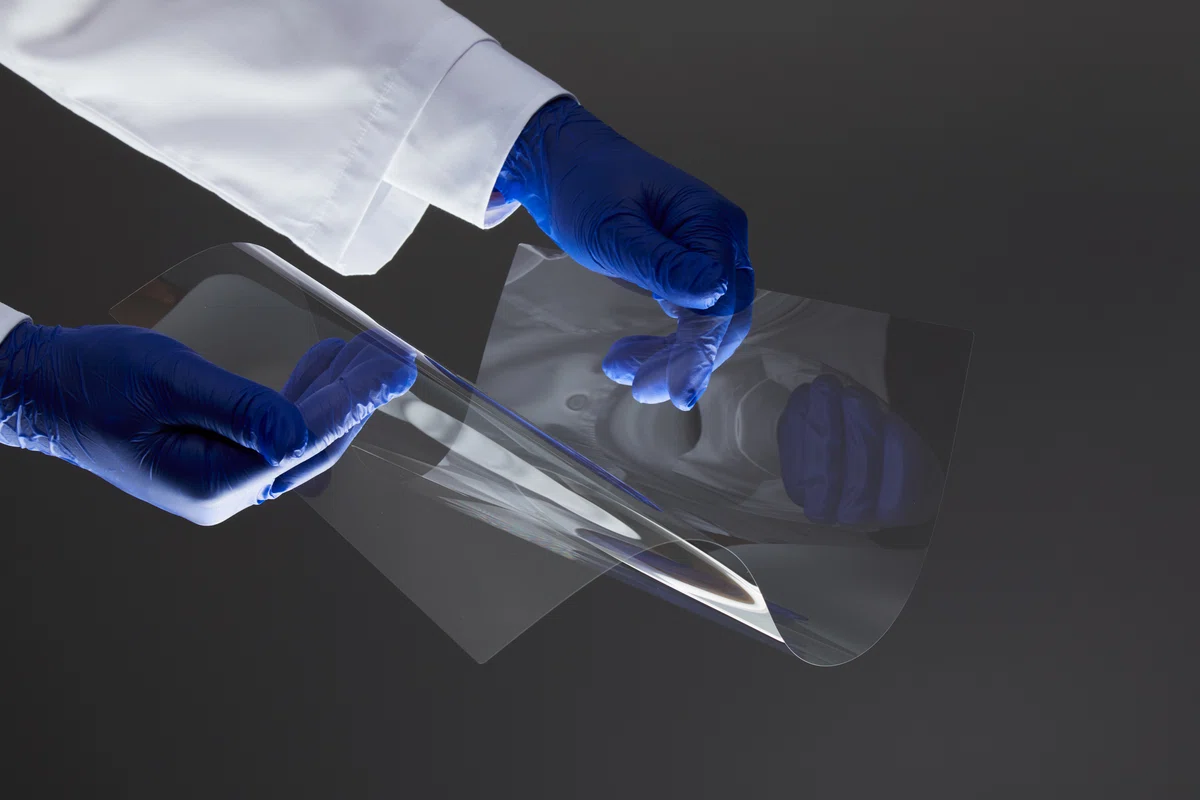

Many years of technological development has led to the successful stable mass production of glass with a thickness of 0.035 mm (35 μm), which was required by the market. The thickness is less than half that of copy paper, which is about 0.1 mm. In July 2020, NEG also succeeded in the development of the world’s thinnest ultra-thin glass with a thickness of 0.025 mm (25 μm). This new material, named Dinorex UTG™, is not only resistant to scratches and impacts but is also thin and bendable.

Dinorex™ is based on a technology developed in 2014. The product name was coined through the combination of “dinosaur” and “rex,” meaning “king” in Latin. It was so named after the image of the strength and toughness of tyrannosaurus. Dinorex UTG™ represents a model that realizes superb bending properties by improving the surface flatness and thickness uniformity while utilizing the chemical treatment technology established for conventional Dinorex™.

Passing a repeated bending test of 200,000 cycles!

Dinorex UTG™ demonstrated its reliability by passing a repeated bending test of 200,000 cycles. An even more remarkable fact is that Dinorex UTG™ was not damaged even in NEG’s in-house repeated bending test of one million cycles. This achievement is a testament to the technology that NEG has cultivated over many years and the outstanding quality of Dinorex UTG™.

In addition, bending to a diameter of 3 mm (a radius of 1.5 mm) or less does not cause Dinorex UTG™ to crack or leave traces of bending. Such high durability, unparalleled foldability, and clarity that leaves minimal traces in the folding section significantly contribute to foldable smartphone technologies, including Motorola’s razr 60.

Dinorex UTG™ does not crack or leave traces even if it is bent to a diameter of 3 mm (a radius of 1.5 mm) or less. (Click on the image.)

Superb flatness which underpins high-definition displays

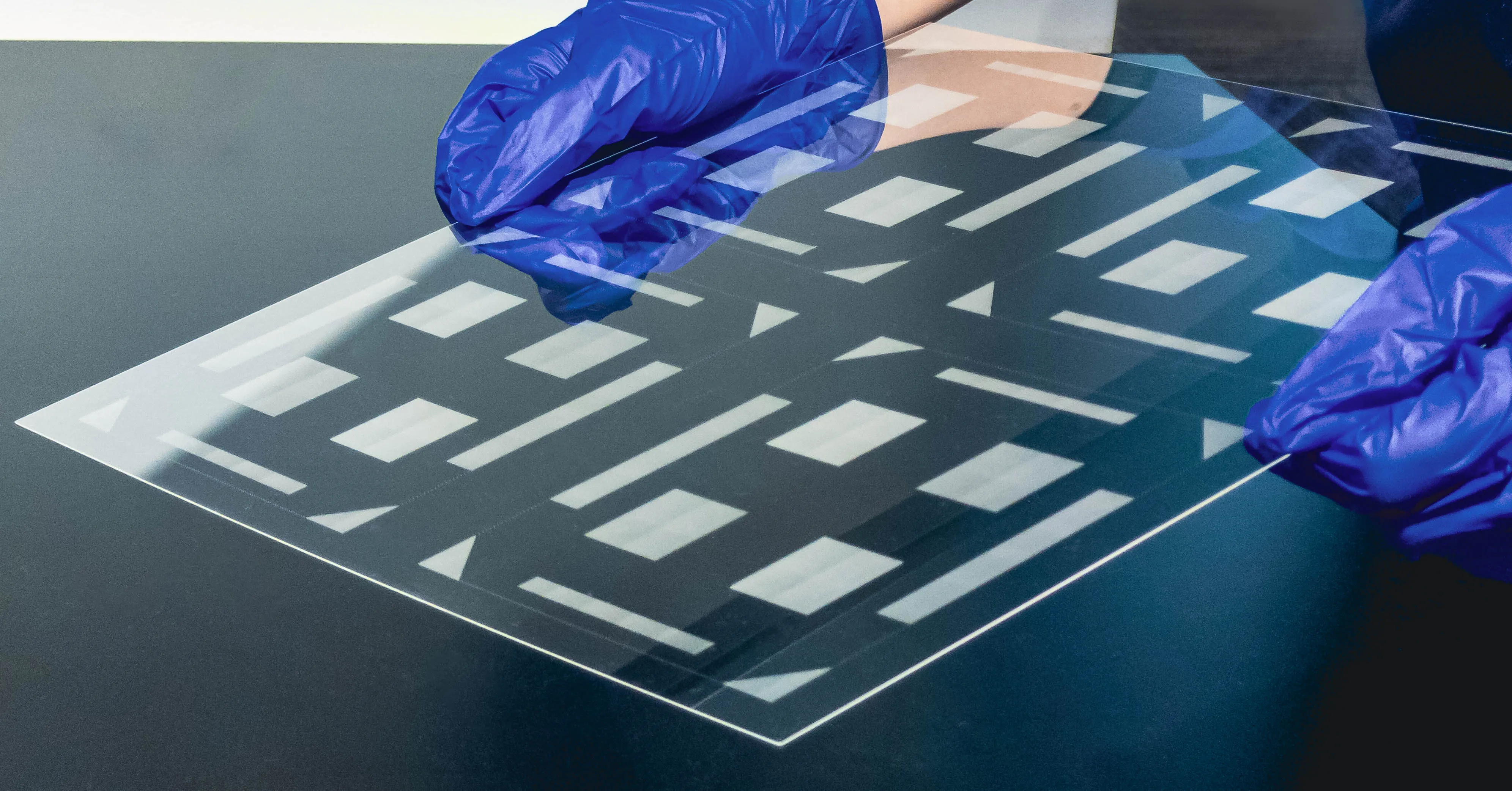

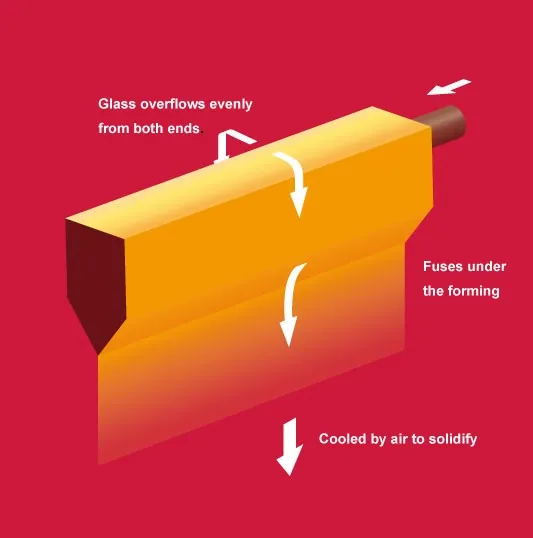

Overseas glass manufacturers also offer ultra-thin glass similar to Dinorex UTG™. However, NEG can form ultra-thin glass by “direct forming” using the overflow technology, without a chemical slimming process. This gives an advantage in terms of flatness, environmental impact, and cost.

In general manufacturing processes of thin glass, post-processing called slimming is performed. In this process, slightly thick glass of 70 μm, for example, is formed and is thinned to 30 μm by chemical treatment using a chemical solution. Slimming involves the use of a chemical solution which evenly melts glass. This chemical solution contains environmentally harmful substances. As the name suggests, direct forming refers to the forming of molten glass directly into a thin sheet. This reduces the time and cost required for post-processing, contributing to a reduction in consumption of the chemical solution and emissions of environmentally harmful substances.

Glass manufactured by direct forming is characterized by superb surface flatness. Here, flatness refers to surface uniformity with minimal unevenness, warping, waviness, and distortion. Inadequate flatness leads to uneven application of the display layer in the manufacturing process of small high-definition displays, such as those for smartphones, resulting in degradation of the final display quality. Notably, regarding high-definition displays which are formed by tiny pixels, even a slight amount of unevenness on the surface adversely affects the quality of the displayed image. For display devices, surface flatness is a critical factor. Excellent flatness is one of the main reasons why Dinorex UTG™ was chosen for Motorola’s razr 50 and razr 60 series.

Potential of Dinorex UTG™, which is made in Japan

Dinorex UTG™ is glass characterized by both flexibility and strength, which revolutionizes the conventional image of glass as being inflexible and fragile. It is highly evaluated for its bending strength and environmental friendliness. Due to its outstanding properties, Dinorex UTG™ has been adopted for foldable displays, including Motorola’s razr 60, and speaker diaphragms. It is expected to be applied to various fields. Dinorex UTG™ is also expected to be deployed to the mobile device field and other applications. Please keep an eye on how Dinorex UTG™, the made-in-Japan ultra-thin glass developed by NEG, will unfold.