MarkAudio’s Challenge to Develop the World’s First Ultra-thin Glass (Special Glass) Speakers

[Article featured in the monthly magazine Stereo]

Fidelitatem Sound Co., Ltd., which is part of the MarkAudio Group, has continued to transcend the limitations of full-range speaker units with unique designs that defy the conventional wisdom of speaker units. On January 15, 2025, the company will launch the Alpair 5G, the world’s first speaker unit using ultra-thin glass (special glass) as a diaphragm, through crowdfunding.

- 1. Challenging a long-standing taboo to deliver glass-based speakers

- 2. A three-party project

- 2-1. Material: Dinorex UTG™, a glass resistant to scratches and impacts, developed by Nippon Electric Glass (NEG)

- 2-2. Processing: 3D processing of delicate special glass into a complex shape by GAIT

- 2-3. Assembly: A process incorporating MarkAudio’s design philosophy

- 3. The world’s first 100 μm ultra-thin glass speakers

- 3-1. Transmission velocity

- 3-2. Damping factor (DF)

- 3-3. Lightweight cones

- 3-4. Extremely linear damping properties

- 4. Speakers carefully designed to deliver a natural sound and enhance the music listening experience

- 5. Overview of MarkAudio’s Alpair 5G full-range speaker unit

- 6. Pre-orders to be taken through crowdfunding!

- 7. Opportunities to listen to a demonstration!

- 7-1. Samples on display!

- 7-2. A demonstration event to be co-hosted by Fidelitatem Sound, Kyohritsu Electronic Industry, and Stereo magazine

Challenging a long-standing taboo to deliver glass-based speakers

Most speaker units use pulp or aluminum cones. Many experienced audiophiles may have a negative image of the sound quality of glass-based speakers due to characteristics such as piercing and unnatural sound.

Unconventional sound clarity and soundstage have been realized by special glass, which is derived from the ultra-thin glass forming technology of Nippon Electric Glass Co., Ltd. (NEG) to ensure smoothness and thickness distribution uniformity and the 3D processing technology of Taiwan’s Glass Acoustic Innovations Co., Ltd. (GAIT) to achieve exceptionally thin processing. This special glass has been turned into products by harnessing MarkAudio’s profound experience. Shunsuke Yoshino, editor-in-chief of the monthly magazine Stereo, listened to a demonstration of the completed Alpair 5G speaker units and commented, “They redefine the standard. If they are used effectively, they are likely to break new ground surpassing conventional speakers.”

A three-party project

Three companies were involved in this project: NEG, based in Otsu City, Shiga Prefecture, which manufactures the Dinorex UTG™ special glass material characterized by high bending strength; GAIT in Taiwan, which processes the special glass into speaker cones; and MarkAudio, which finishes the final speaker units using the special glass cones.

Material: Dinorex UTG™, a glass resistant to scratches and impacts, developed by NEG

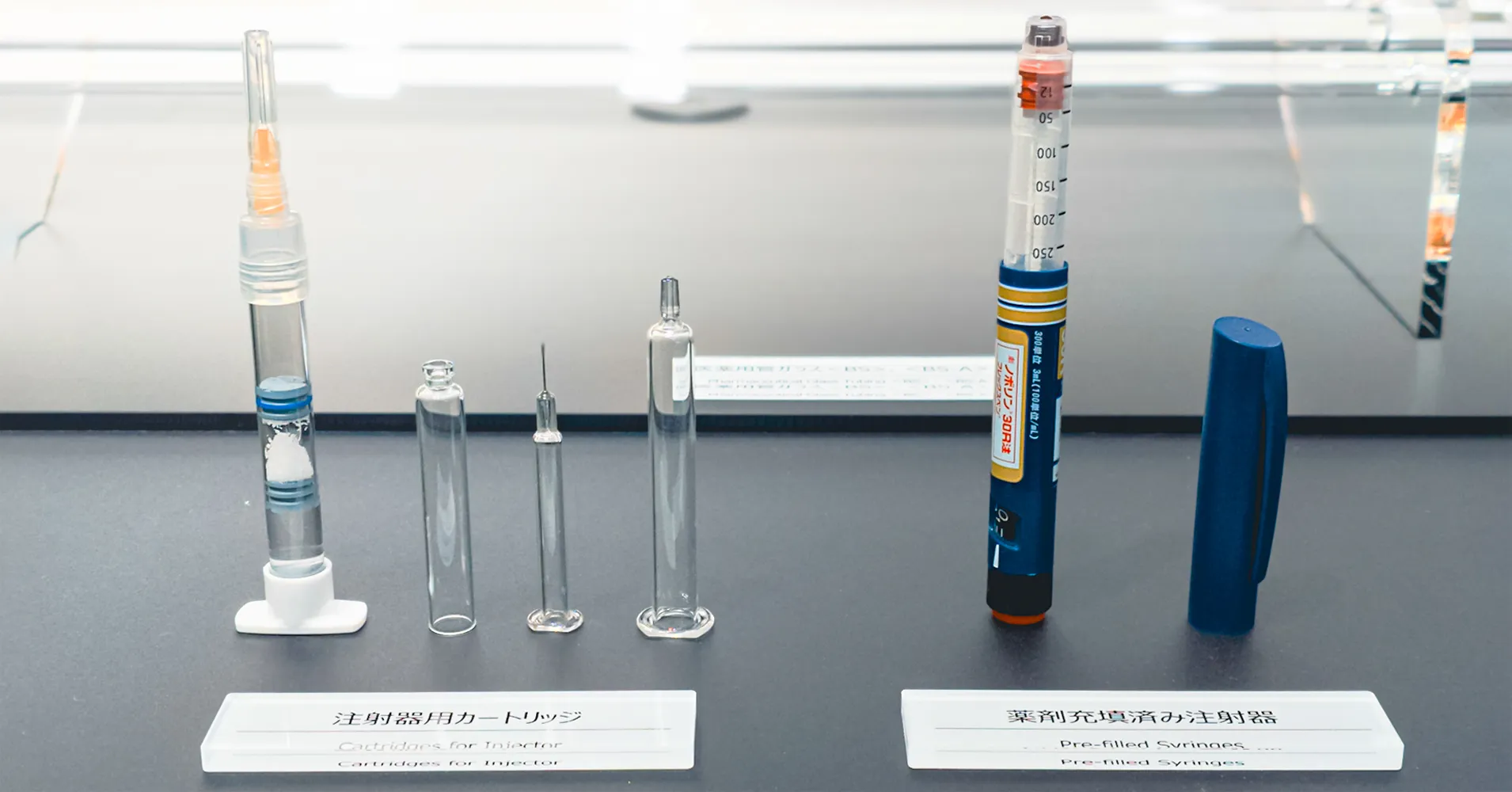

The special glass used as the material for the speaker diaphragms is special ultra-thin break-resistant glass, which has also been used recently for the display cover glass of foldable smartphones.

Branded as Dinorex UTG™, this material is manufactured by the overflow forming process and is characterized by high surface smoothness and uniform thickness distribution. By enhancing the material’s strength through chemical strengthening (ion exchange), NEG succeeded in realizing break-resistant glass despite its thinness.

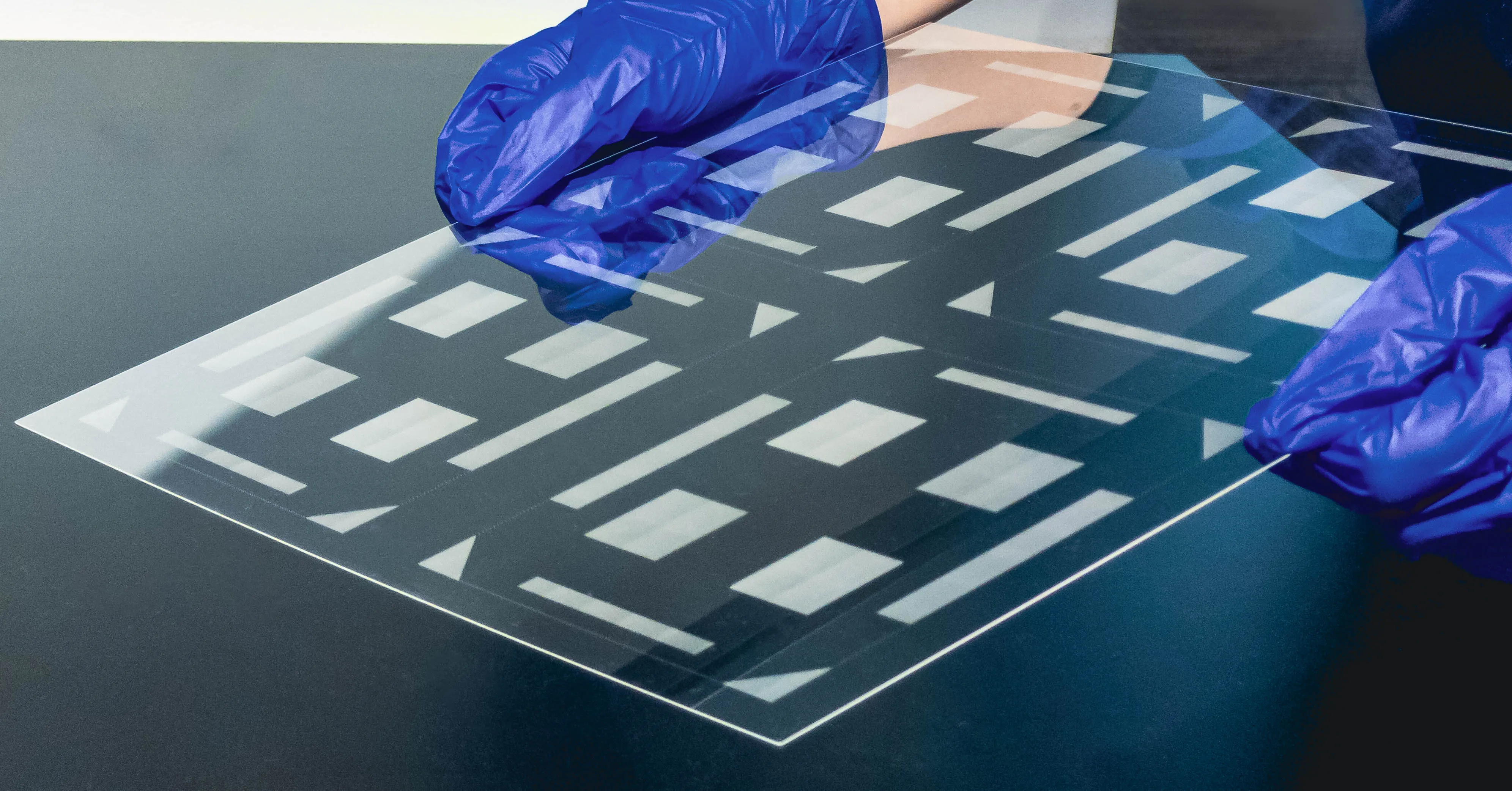

Processing: 3D processing of Dinorex UTG™ into a complex shape by GAIT

GAIT, a Taiwanese company, specializes in molding this special glass material into speaker cones. Patented technologies are used to mold the special glass speaker cones. The company actively exhibits the speaker cones made of this new material with superb acoustic properties at audio shows in order to sell them to global speaker manufacturers. MarkAudio is the first company to use special glass for hi-fi speakers.

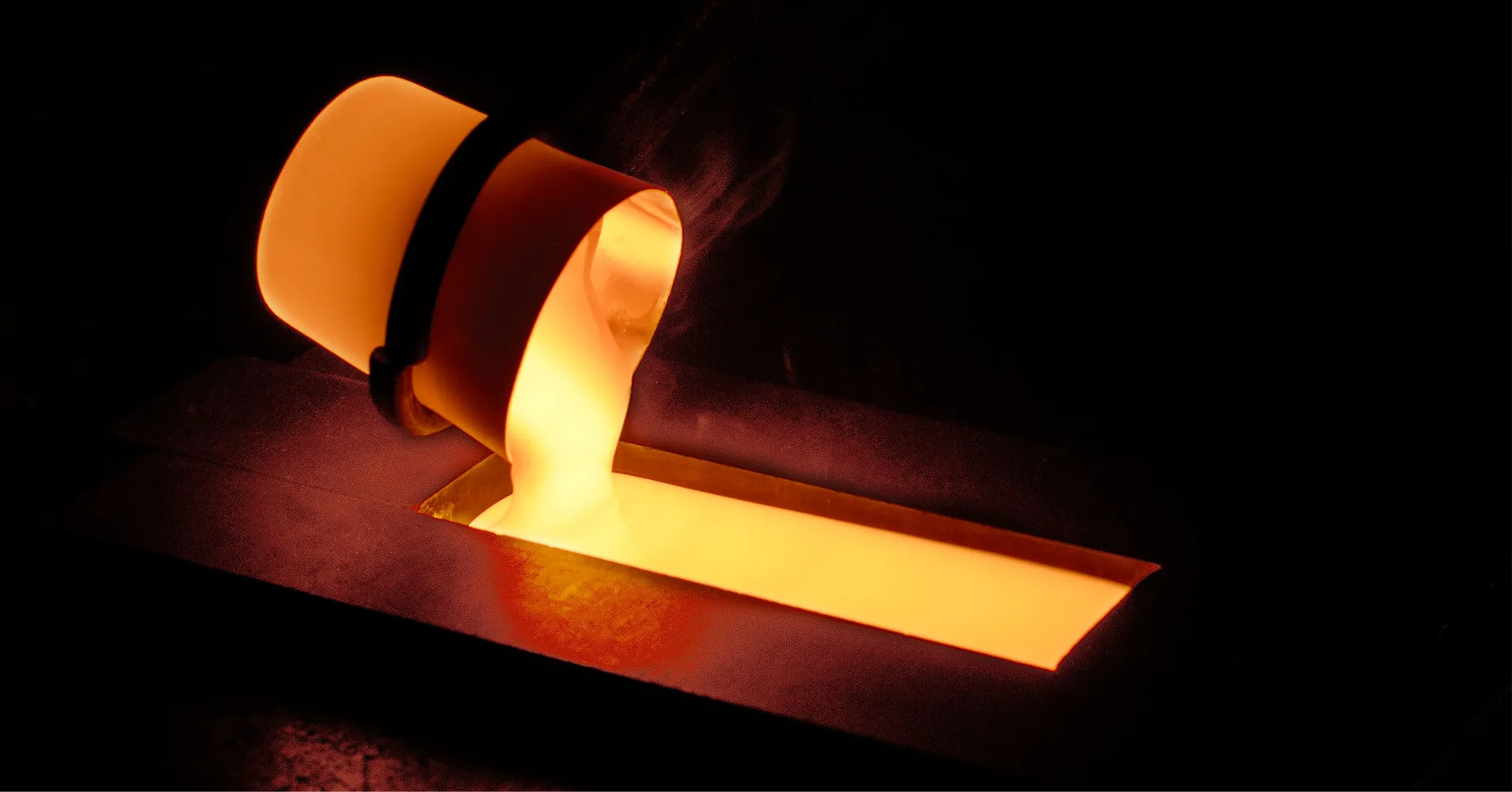

At GAIT’s plant, Dinorex UTGTM sheets, which are as thin as paper, are placed on speaker cone molds, which go through a small furnace at 700°C on a conveyor and are cooled slowly. Finished speaker cones are soaked in a special chemical to increase their strength. An electron microscope is subsequently used to measure the roundness and edges. Only cones that pass rigorous inspection are shipped.

Assembly: A process incorporating MarkAudio’s design philosophy

At MarkAudio’s plant in Guangzhou, adhesive is evenly applied to a frame using a machine to bond a damper. MarkAudio carefully manages the adhesive material and the amount in its operations as key factors that determine the sound quality. Subsequently, a voice coil, which is set to a jig, is put into place and left to dry. Then, an ultra-thin glass cone is bonded to the voice coil. Finally, a center cap is bonded to the voice coil and the ultra-thin glass cone, and the magnet is magnetized.

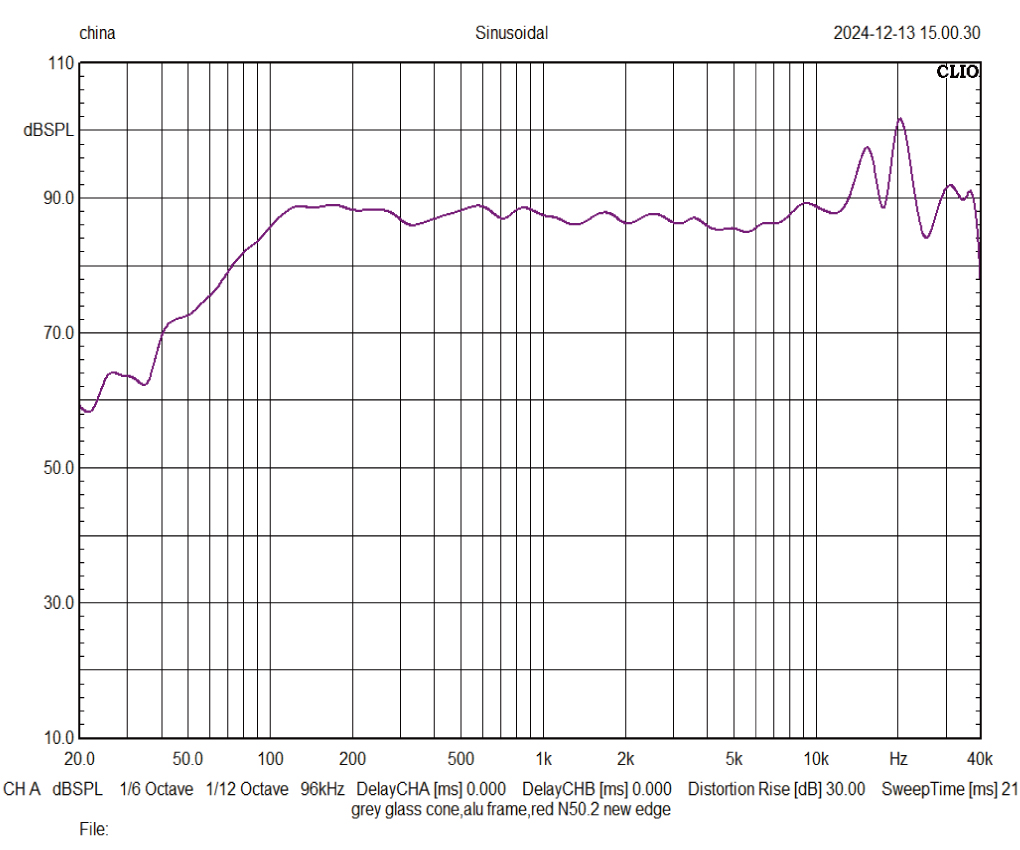

When a finished speaker unit was measured in an anechoic chamber, it exhibited a flat frequency response up to 40 kHz (guaranteed frequency response of the measurement microphone), with minimal unwanted resonances in the audible range from low to high frequencies. Such wide-range and flat characteristics are considered to be the best ever for full-range speakers.

The world’s first 100 μm ultra-thin glass speakers

An engineer at Fidelitatem Sound learned about the ultra-thin glass by chance. The engineer was amazed at the properties of the ultra-thin glass, which was originally developed mainly as bendable glass.

Its acoustic transmission velocity is higher than that of titanium, with its weight being lighter than that of aluminum and its damping factor being about half that of paper. Such properties were irresistibly appealing for the speaker unit manufacturer. Based on the belief that such properties would achieve innovative audio playback through a robust speaker design, the engineer persuaded the production division of MarkAudio to launch the development of the world’s first authentic audio-grade ultra-thin glass speakers.

According to MarkAudio’s documents, the main properties required of cone materials are low weight, high transmission velocity, and a low damping factor. However, because these three factors are mutually contradictory, it is extremely difficult to find an ideal material. In general, paper, alloys, and polypropylene are used depending on the purpose.

These three factors are determined by attack, decay, sustain, and release, which are elements of audio playback of the sound of musical instruments. Attack depends on the transmission velocity and weight, while decay and sustain depend on the damping factor.

The properties of the time axis are extremely important for accurate sound playback of speakers. NEG’s glass diaphragm is considered to be close to ideal in terms of attack and decay/sustain. The material is expected to ensure delicate, crystal-clear sound, just like 8K images in visuals.

Transmission velocity

| Material | Beryllium (Be) | DinorexUTG(Glass) | Aluminium | Titanium (Ti) | Paper | Polypropylene |

|---|---|---|---|---|---|---|

| Transmission velocity (M/S) | 12,500 | 5,800 | 5,400 | 5,200 | 3,200 | 1,100 |

| Relative Ratio (Paper=1.0) | 3.90 | 1.81 | 1.69 | 1.63 | 1.00 | 0.34 |

The responsiveness and crispness of the speaker sound are determined by these elements. The measured values of the material transmission velocity above indicate that sound transmission velocity of glass is higher than that of titanium and aluminum cones and 1.8-fold that of paper cones, and is ideal for playback of piano and cymbal sounds.

Damping factor (DF)

| Material | Beryllium (Be) | DinorexUTG(Glass) | Aluminium | Titanium (Ti) | Paper | Polypropylene |

|---|---|---|---|---|---|---|

| Damping Factor (η) | 0.005 | 0.015 | 0.002 | 0.002 | 0.040 | 0.080 |

| Relative Ratio (Aluminium=1.0) | 2.50 | 7.50 | 1.0 | 1.0 | 20.0 | 40.0 |

The tone of speakers is determined by the damping properties of materials, such as those of cones and frames, and wood used for the enclosures. The resonant frequency of a material is another factor that affects sound playback. The transmission velocity and damping factor shown above go beyond the conventional idea of glass, realizing quick and clean decay.

Relative density

| Material | Beryllium (Be) | DinorexUTG(Glass) | Aluminium | Titanium (Ti) | Paper | Polypropylene |

|---|---|---|---|---|---|---|

| Relative Density (Paper=1.0) | 1.85 | 2.4 | 2.7 | 4.5 | 1.0 | 0.92 |

Light weight is essential for the mid- and high-frequency characteristics of speakers. The above table shows a comparison with pulp cones with a mean value of 1. Given that its thickness is 100 μm, the Dinorex UTG™ ultra-thin glass is even lighter in relative terms.

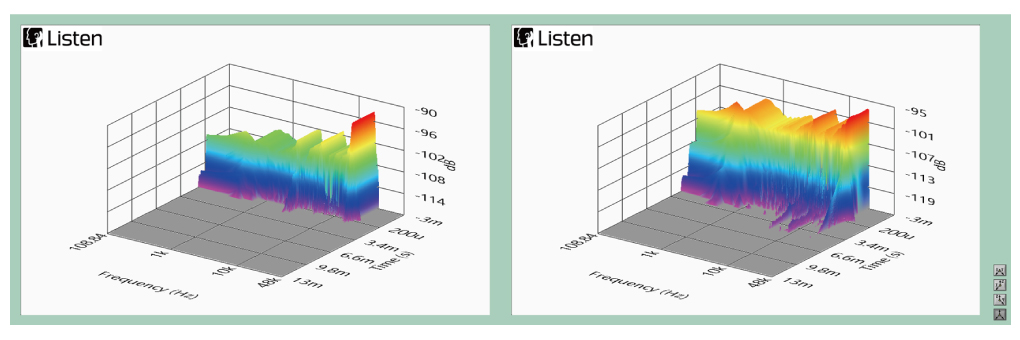

Extremely linear damping properties

The figure above shows a comparison of damping properties between the ultra-thin glass and polymethacrylimide (PMI) foam (whose damping factor is relatively close).

The decay time of the ultra-thin glass is very flat across the entire frequency range. This proves there is clean decay across the entire sound spectrum in addition to superb damping performance. It testifies to the fact that the Alpair 5G’s playback is almost true to source.

Speakers carefully designed to deliver a natural sound and enhance the music listening experience

Mr. Takashi Iwai, an audio critic, listened to the sound of the speaker units and commented as follows:

“The speakers offer outstanding sound separation compared to conventional full-range speakers. They deliver lifelike sound not achieved by other materials. Notably, they are ideal point sources in expressing spatial depth. Natural reproduction of music is achieved by clear separation of musical instruments, high purity, fast attack, and quick decay with the respective resonances of musical instruments. The speaker units are refined based on a robust design to enhance the music listening experience, while pursuing excellent performance.”

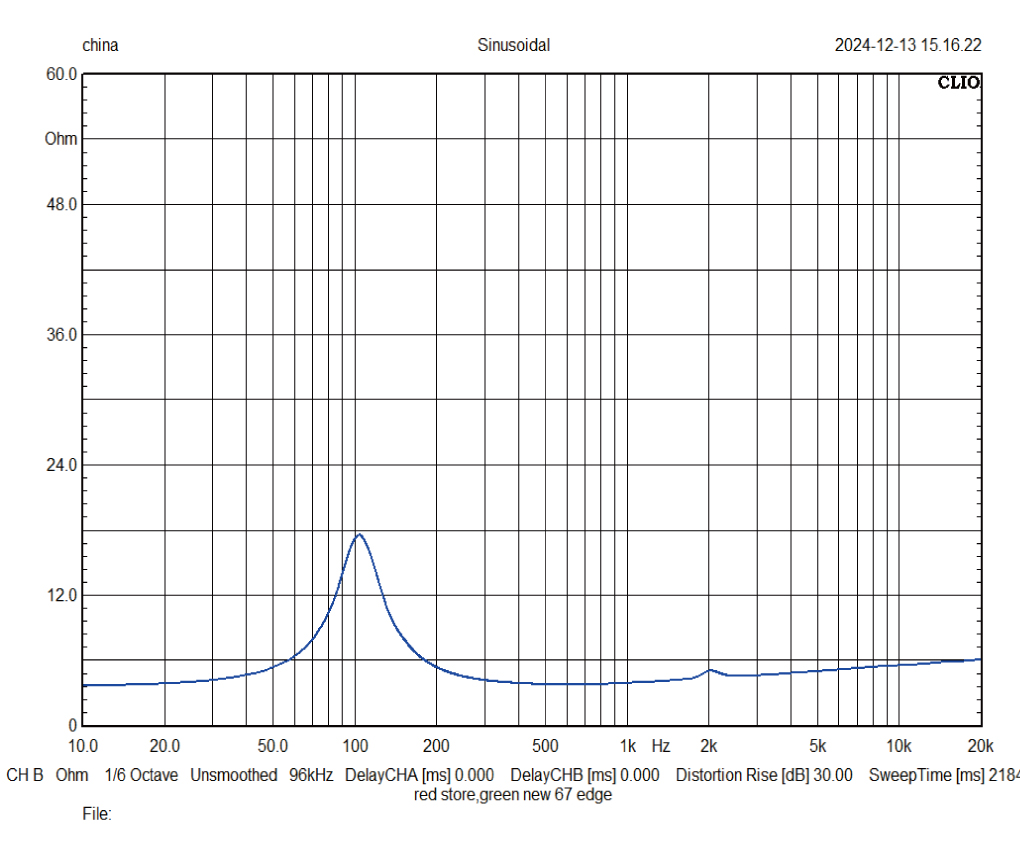

Overview of MarkAudio’s Alpair 5G full-range speaker unit

・Type: 8 cm full-range

・Impedance: 4Ω

・FS: 107.5 Hz

・Le: 0.0423 mH (1 kHz)

・Fs: 107.5 Hz

・Mms 1.93 g

・Cms: 1.13 mm/N

・Bl : 2.55 T×m

・Qms: 2.74

・Qes: 0.68

・Qts: 0.54

・SPL: 85.6 dB

・Sd: 28 cm²

・Rated Input: 10 W

・Vas: 1.26 L

Pre-orders to be taken through crowdfunding!

Pre-orders for the speaker units will be taken on GREENFUNDING, a crowdfunding site. A pair is expected to be priced at 20,000 yen or less (early bird discounts available). It will also come as a set with a cabinet.(Note: This pre-ordering service is already finished.)