Ultra-thin Glass Diaphragms, the Key to Next-Generation Quality Sound

- What is a diaphragm?

- “World-first” ultra-thin glass diaphragm

- Producing high-definition sound with a fast attack time

- Speaker diaphragms: comparison of features by material

- Why did GAIT choose NEG?

- GAIT’s outstanding technical capabilities to realize 3D processing of ultra-thin glass

- NEG’s high-quality ultra-thin glass and careful quality control

- A strategic partnership between Japanese and Taiwanese companies targeting the global market

What is a diaphragm?

Speakers work by converting electrical signals into vibrations that move air—producing sound. While we rarely think about it, this mechanism relies heavily on a component called the diaphragm.

A coil, which converts electrical signals into vibrations, and a diaphragm, which produces sound by vibrating air, are built into a speaker. Diaphragms are generally made of paper, resins, or metals, but the choice of using glass has attracted attention.

“World-first” ultra-thin glass diaphragm

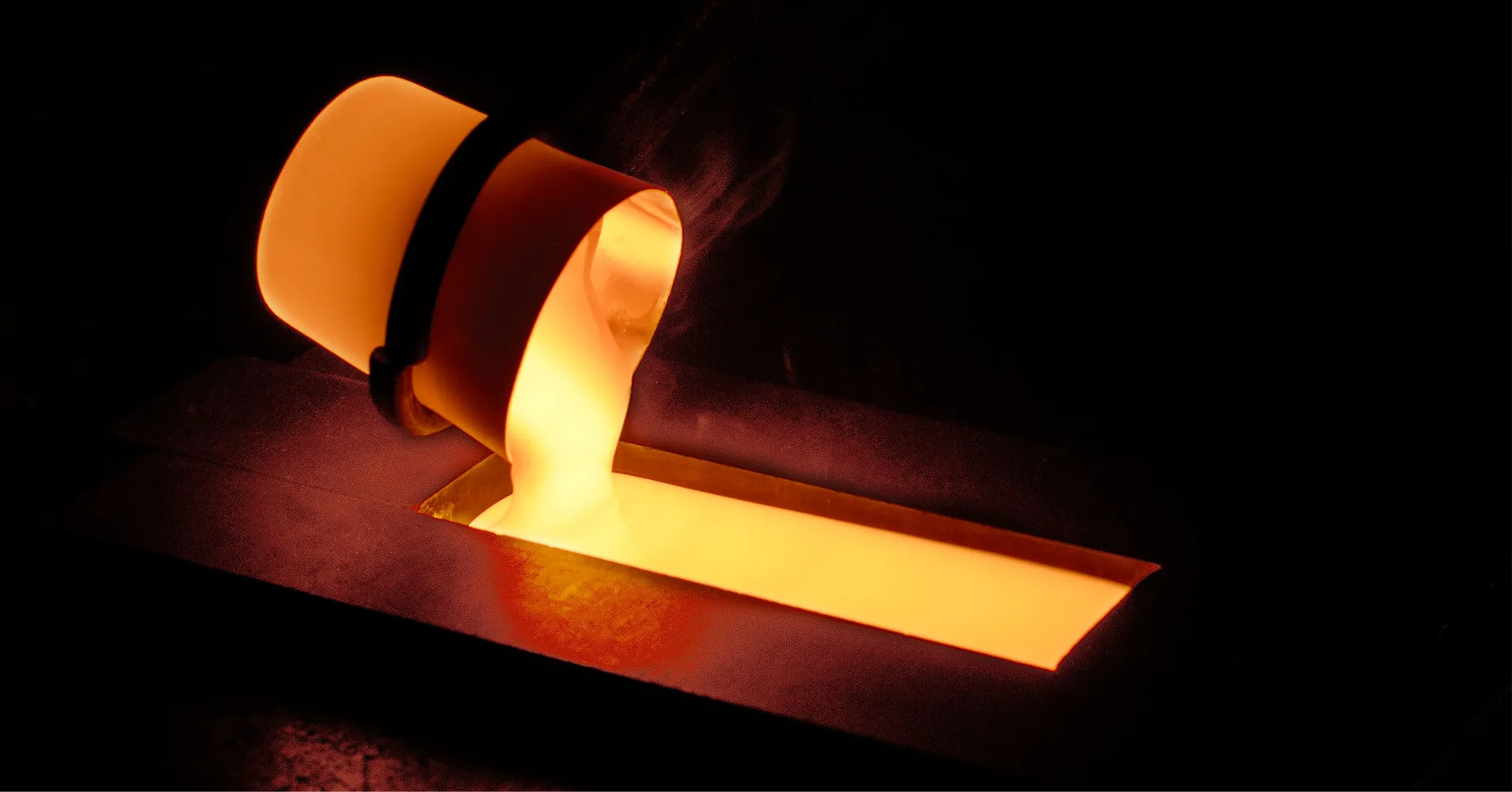

[Photo 2] shows an ultra-thin glass diaphragm developed through collaboration between Nippon Electric Glass (NEG), a leading company of special glass, and GAIT, a Taiwanese glass diaphragm manufacturer. This is a new product created by processing Dinorex UTGTM ultra-thin glass [Photo 1], which is one of NEG’s special glass products, using GAIT’s sophisticated technical capabilities. The application of ultra-thin glass not only offers a strikingly elegant appearance but also delivers superior acoustic performance through rapid response and reduced distortion.

What is the secret behind this ultra-thin glass diaphragm, which appears to be a piece of glassware?

We interviewed Ms. Wan, who is in charge of GAIT at NEG and works for the Display Glass Sales Div., about the process leading up to the completion of this new product through collaboration between NEG and GAIT and the future outlook.

Producing high-definition sound with a fast attack time

Wan “Ultra-thin glass diaphragms not only have a beautiful, transparent appearance, but their greatest strength lies in their exceptionally fast attack time. This results in highly responsive performance and the ability to faithfully reproduce even the most delicate nuances of the original sound. We’ve already delivered prototypes ranging from compact earphones to large speakers, and users consistently praise the prototypes, noting a 'clear, refined sound' and describing it as delivering a 'unique tonal character unattainable with traditional materials.”

Key Features of Ultra-Thin Glass Diaphragms:

-

High rigidity – Enables rapid attack and suppresses breakup vibrations.

-

High internal loss (damping performance) – Minimizes reverberation and prevents muddy sound.

-

Ultra-lightweight and thin(low specific gravity) – Enables precise rendering of delicate audio textures while reducing inertia.

-

High strength and hardness – Provides excellent resistance to cracks and scratches.

Wan “Compared to conventional materials like paper or resin, ultra-thin glass offers significantly higher rigidity, enabling swift response and precise sound reproduction across a wide frequency range. While metals are also rigid, they tend to prolong vibration, resulting in lingering reverberation and a somewhat muddy tone—plus, they’re relatively heavy. In contrast, ultra-thin glass is light enough to reproduce delicate sounds with clarity. Its high internal loss also means it absorbs vibrations quickly, shortening reverberation and maintaining clarity even when sounds overlap.”

Why does an ultra-thin glass diaphragm produce a clean and clear sound? It is because of the physical properties of ultra-thin glass, which is hard and realizes minimal reverberation.

Wan “Because ultra-thin glass is harder than paper and resins, it can vibrate diaphragms responsively*1andaccurately reproduce sound over a wide playback frequency range. Metals are hard but do not allow vibration to subside easily. Prolonged reverberation makes the sound cloudy. On the other hand, ultra-thin glass is characterized by a short reverberation time (*2 due to high internal loss), which prevents resonance with subsequent sounds and helps produce a clear sound.”

In addition, unlike paper and resins, ultra-thin glass is resistant to environmental changes, such as temperature and humidity, and does not deteriorate easily over time.

*1 Ultra-thin glass has high rigidity (resistance to bending). When used for diaphragms, it enables piston motion (precise reciprocating motion) over a wider frequency range.

*2 Materials with high internal loss absorb vibration, resulting in high attenuation speeds. This prevents resonance with subsequent sounds and helps produce a clear sound, enabling playback with higher definition.

When a diaphragm is produced using heavy materials, such as metals, vibration requires more energy and time. As a result, a slower attack time and a restricted playback frequency range hinder realization of a high-quality sound.

The use of NEG’s ultra-thin glass reduces the weight of diaphragms, ensuring both the hardness required for quality sound and excellent acoustic properties. In general, diaphragms with a thickness of 0.1 mm are considered “thin.” The thickness has been minimized to 0.025 mm (25 μm) by NEG’s ultra-thin glass manufacturing technology and GAIT’s processing technology. The synergies of the two companies’ technologies have enabled the development of glass diaphragms with a fast attack time that are capable of reproducing sharp, clear, high-fidelity, and natural sound.

Speaker diaphragms: comparison of features by material

| Material | Beryllium (Be) | DinorexUTG(Glass) | Aluminium | Titanium (Ti) | Paper | Polypropylene |

|---|---|---|---|---|---|---|

| Transmission velocity (M/S) | 12,500 | 5,800 | 5,400 | 5,200 | 3,200 | 1,100 |

| Relative Ratio (Paper=1.0) | 3.90 | 1.81 | 1.69 | 1.63 | 1.00 | 0.34 |

Responsiveness and crispness, the basic playback properties of speakers, are determined by these factors. Based on the measured values above, the transmission velocity of Dinorex UTG™ is higher than that of titanium and aluminum cones, and is 1.8-fold that of paper cones.

| Material | Beryllium (Be) | DinorexUTG(Glass) | Aluminium | Titanium (Ti) | Paper | Polypropylene |

|---|---|---|---|---|---|---|

| Damping Factor (η) | 0.005 | 0.015 | 0.002 | 0.002 | 0.040 | 0.080 |

| Relative Ratio (Aluminium=1.0) | 2.50 | 7.50 | 1.0 | 1.0 | 20.0 | 40.0 |

| Material | Beryllium (Be) | DinorexUTG(Glass) | Aluminium | Titanium (Ti) | Paper | Polypropylene |

|---|---|---|---|---|---|---|

| Relative Density (Paper=1.0) | 1.85 | 2.4 | 2.7 | 4.5 | 1.0 | 0.92 |

The lighter the material, the more responsive and crisp the speaker becomes. The table shows the comparison with the mean value of paper cones being 1. Glass cones of Dinorex UTG™ are lighter than aluminum or titanium cones.

GAIT is the exclusive brand and sole supplier of glass diaphragms, trusted by international brands across automotive audio, high-fidelity speakers, luxury audio systems, and consumer electronics—including smartphones, earphones, and headphones.With proprietary patents and advanced glass processing technology, which integrate our patents and trade secrets , GAIT has redefined the acoustic diaphragm, combining exceptional performance, precise 3D design, and an elevated sensory experience, while NEG has developed and supplied high-precision, high-grade special glass products to the cutting-edge display and electronics fields. Co-creation by the two companies is expected to further evolve ultra-thin glass diaphragms.

Why did GAIT choose NEG?

The two companies encountered each other at an exhibition in Taiwan in April 2023. NEG and GAIT exhibited at the same venue, and this coincidence led to interactions between the two companies.

"Wan“ We received an inquiry from GAIT that they were highly interested in using NEG’s ultra-thin glass. Although NEG had not yet commercialized speaker diaphragms at that time, the company had been exploring audio applications for about a decade, proposing its ultra-thin glass technology to audio manufacturers. However, no partner with precision 3D glass processing capabilities like GAIT had been found until then. However, NEG had long been seeking new applications for its paper-thin glass technology, including in the audio sector, though no viable productization partner had emerged—until GAIT. Thus, NEG sent samples of the Dinorex UTGTM ultra-thin glass, which is chemically strengthened glass,*3 to GAIT. This developed into a strategic partnership with GAIT.”

*3 Chemically strengthened glass refers to glass whose surface is strengthened by special chemical treatment. The strength is five-fold or morethat of ordinary glass. In chemical treatment, glass containing sodium ions (Na+) is immersed in a potassium nitrate solution containing potassium ions (K+). The Na+ ions on the surface of the glass are replaced by K+ ions, which have a larger diameter in the solution. This process is known as “ion exchange.” Even if stress due to an external impact or force to expand a crack on the glass surface (tensile stress) is applied, compressive stress is created on the surface of the glass in the opposite direction. Because the stress is offset, it becomes difficult for the crack to propagate, making the glass less likely to break.

For details, refer to the Dinorex UTG ™ product page.

GAIT’s outstanding technical capabilities to realize 3D processing of ultra-thin glass

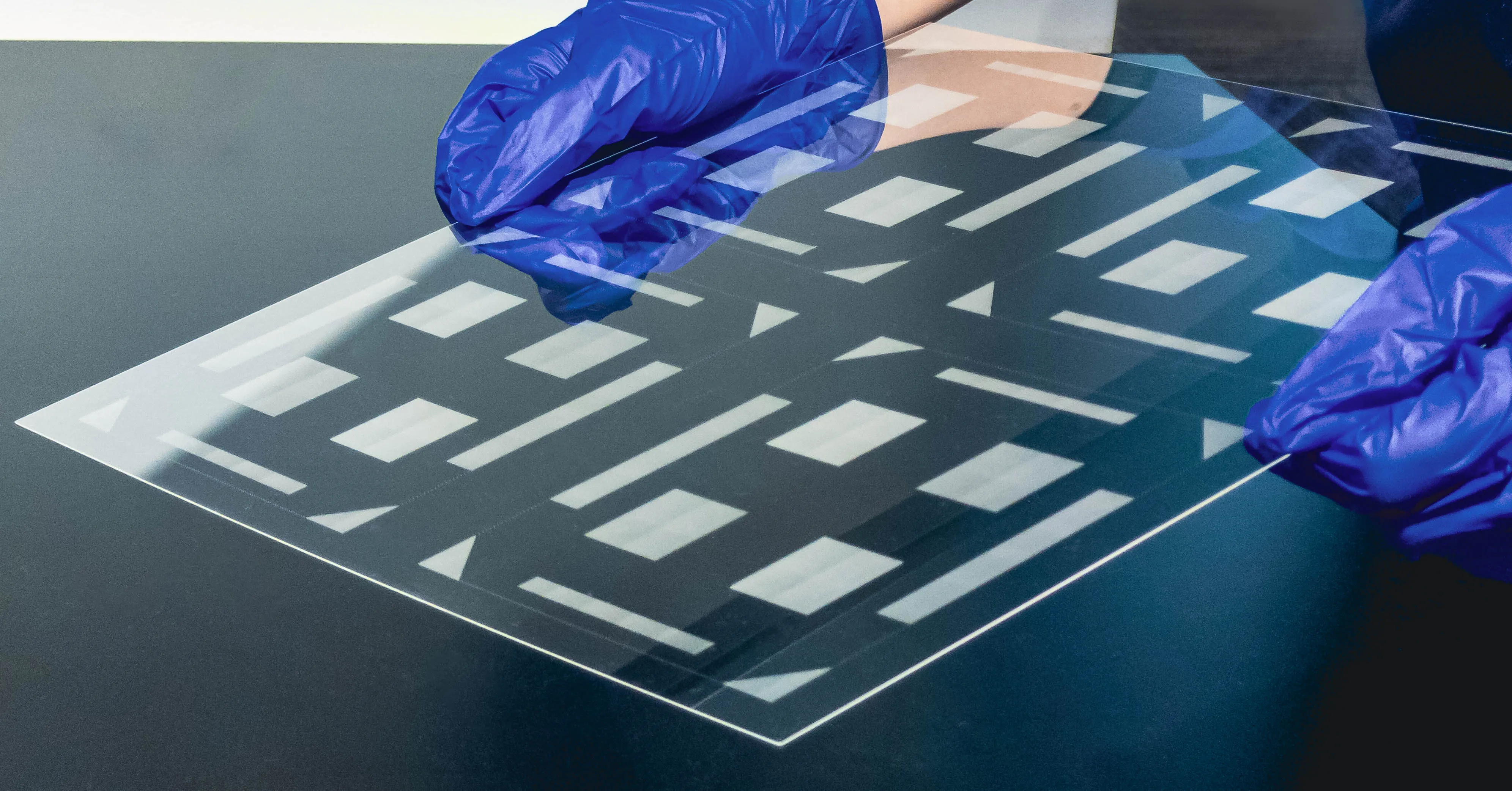

GAIT possesses world-leading expertise in processing ultra-thin glass, including patented technologies for precise 3D shaping with minimal surface distortion.

Its strength lies in the capabilities to perform 3D processing of extremely thin glass, whose thickness is 0.4 mm to 0.025 mm (25 μm), while maintaining a high level of flatness (with minimal unevenness, warping, and waviness on the surface). We asked Ms. Wan, who frequently visited GAIT and witnessed the on-site operations, about the advantages of GAIT’s technical capabilities.

Wan “The first key point is that GAIT has expertise in glass. In addition, GAIT has technologies to fully utilize 3D processing equipment. This is their competitive advantage. In general, processing of thin glass is likely to cause problems, such as failure to maintain uniform thickness and form precise shapes, and generation of wrinkles. Thin materials also pose a risk of breaking during processing. Few manufacturers can perform 3D processing with excellent flatness while comprehensively controlling these factors.”

NEG’s high-quality ultra-thin glass and careful quality control

Ms. Wan said that GAIT decided to choose NEG’s ultra-thin glass based on two main factors:

-

Excellent flatness and uniformity, which are essential for ultra-thin glass diaphragms; and

-

A stable supply of products under strict quality control and comprehensive customer support.

Wan “NEG’s ultra-thin glass earned high marks for its exceptional flatness and uniformity—both critical for precision forming in acoustic applications. This is a very important factor. If glass is not flat enough, unevenness remains after forming. NEG was highly rated for realizing an extremely flat and smooth surface regardless of the glass thickness.”

What about “strict quality control”?

Wan “Glass is a fragile and difficult-to-handle material. For example, strengthened glass, including Dinorex UTG™, is resistant to impacts on the glass surface but is susceptible to impacts on the edge (cut surface of the glass). For this reason, NEG applies meticulous edge treatment during production to smooth the vulnerable cut surfaces of glass—ensuring both durability and consistent quality to ensure a stable supply of high-quality glass.”

NEG’s advanced manufacturing technology and quality control to offer high-quality glass of varying thickness were highly evaluated.

A strategic partnership between Japanese and Taiwanese companies targeting the global market

In April 2024, one year after the two companies met, NEG saw the future potential of the ultra-thin glass diaphragm business and decided to take a stake in GAIT. The two companies formed a strategic partnership.

The speaker diaphragm segment of the global audio market is projected to reach USD 27 billion, according to GMI research.This marks NEG’s first entry into the audio speaker market. However, by adopting a material-first approach that highlights the inherent capabilities of ultra-thin glass itself, NEG aims to deliver entirely new product value not achievable with conventional materials. The fusion of GAIT’s advanced 3D glass processing expertise and NEG’s high-precision specialty glass manufacturing is expected to unlock novel possibilities and applications that extend beyond traditional boundaries.

We invite companies who see the potential in co-developing new solutions with Dinorex UTG™ to contact us. For product-related inquiries, please use the contact form below.

<<Contact regarding this article>>

PR Office, Administrative Division Phone: +81-77-537-1702 (dial-in)

<<Contact regarding products>>

Please fill in the form below.