Evolving Syringe Designs and Japanese Technology—The Current State of the Pharmaceutical Container Market

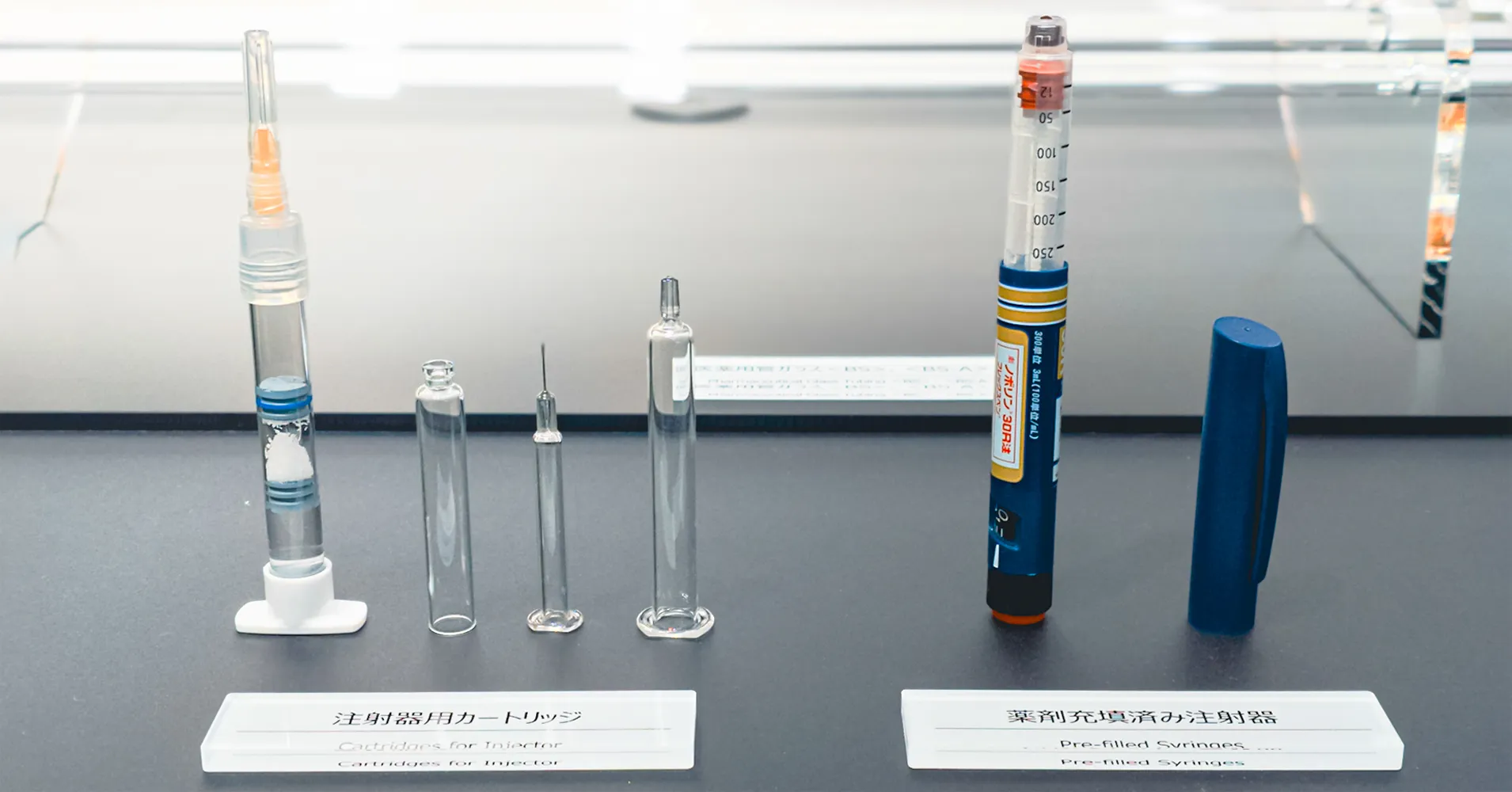

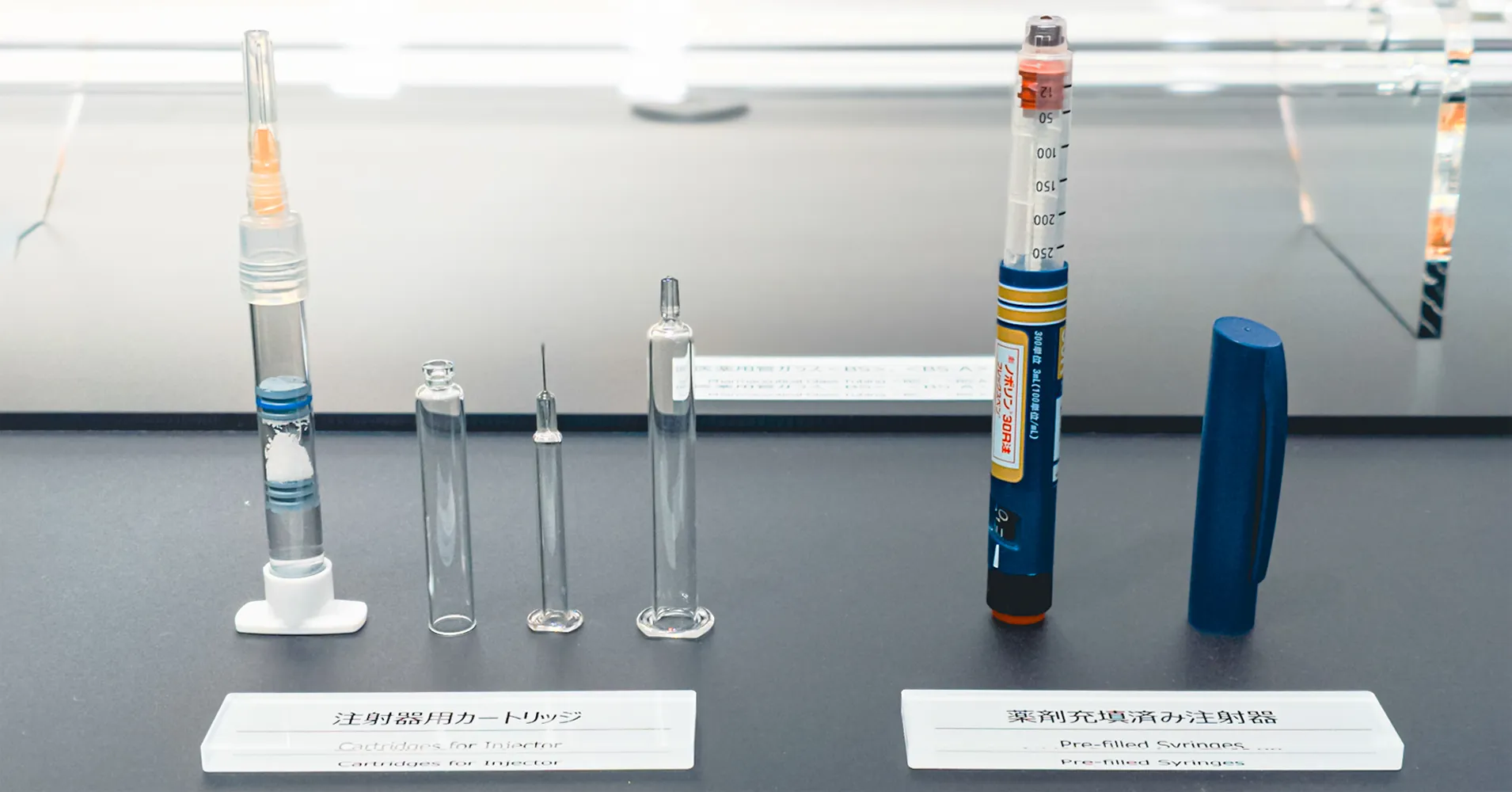

The pharmaceutical container market is currently undergoing a major transformation. While vials and ampoules still dominate the market size, demand for pre-filled syringes and syringe cartridges is rapidly increasing worldwide, driven by efforts to improve efficiency and safety in healthcare settings.

Accelerating this trend is the rapidly growing GLP-1* drug market. The market is expanding at an annual rate of approximately 33%, driving a surge in demand for syringe cartridges that can be directly fitted with the drugs. Adoption is expected to spread not only in Europe and the US but also in emerging markets like China and India, fueling demand for pharmaceutical containers.

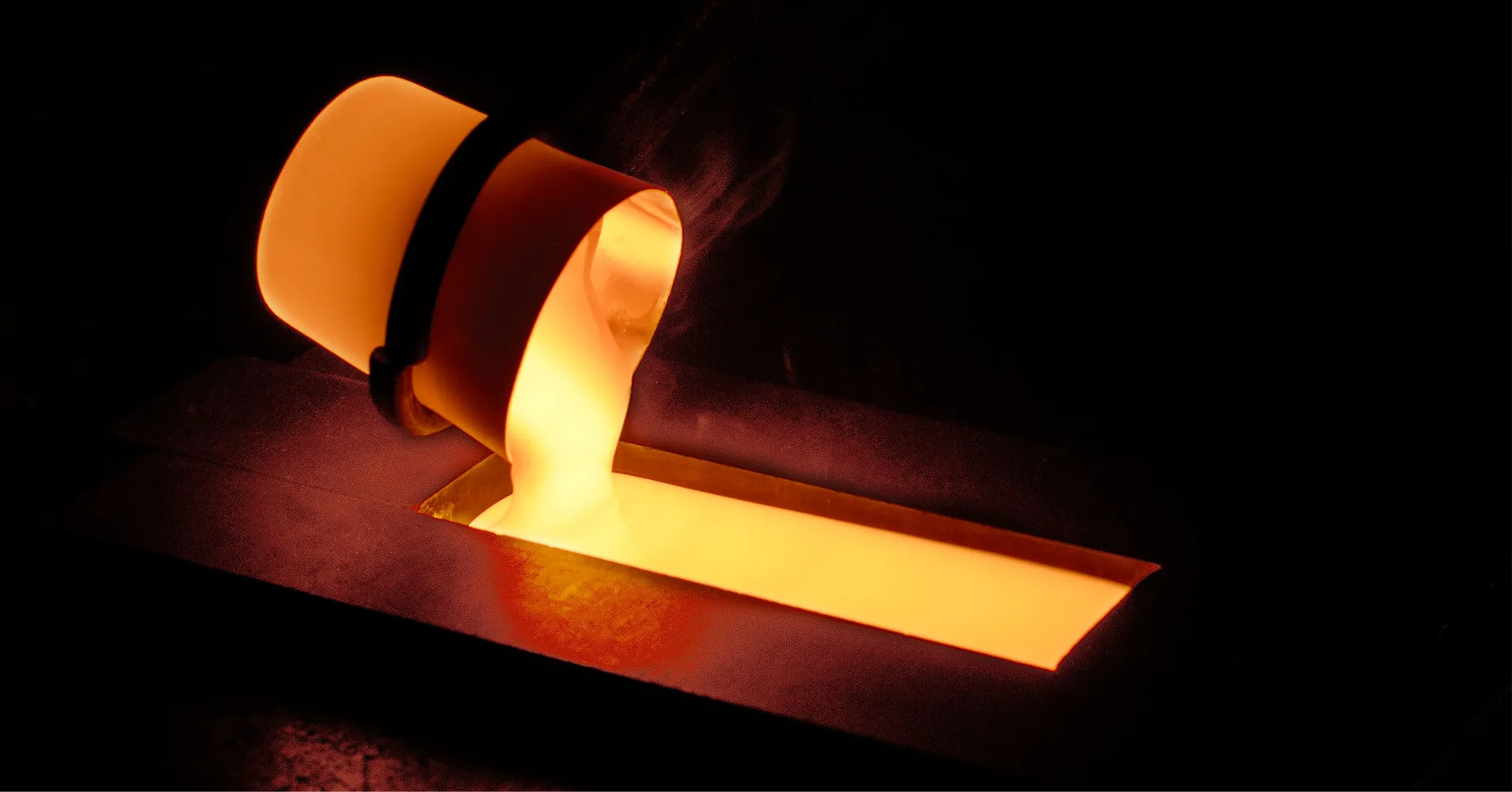

At its core is borosilicate glass, known as a material suitable for pharmaceutical containers. It exhibits low reactivity with drugs, excellent heat resistance and chemical resistance, and has become the standard material from a quality assurance perspective.

In Japan, the only manufacturer producing glass tubing for pharmaceutical containers is Nippon Electric Glass (NEG). For many years, NEG has supplied borosilicate glass tubing to the pharmaceutical industry. Its applications span pre-filled syringes, syringe cartridges, ampoules, vials, and more, with global adoption progressing in response to changes in drug formulations.

-

GLP-1 is a hormone secreted from the small intestine. It promotes insulin secretion when blood glucose levels are high and also suppresses appetite. It is attracting attention as a treatment for diabetes and obesity.

The Transformation of Pharmaceutical Containers and Global Social Challenges

One of the serious social challenges facing modern society is the rapid shift in demographics. While emerging economies continue to experience population growth, aging is progressing rapidly, particularly in developed nations.

To address these demographic shifts, new pharmaceuticals are being developed. Breakthrough medicines are emerging one after another, including mRNA vaccines—known for COVID-19 vaccines—as well as anti-obesity drugs, cancer immunotherapies, and Alzheimer's disease treatments.

Furthermore, to support these new drugs and the efficiency of medical settings, pharmaceutical containers—particularly glass containers—are widely used as products that support the storage and supply of pharmaceuticals.

This article explains the growing demand for pharmaceutical containers against the backdrop of global social challenges and the emergence of new drugs, and details the role and usage examples of glass tubing for pharmaceutical containers provided by NEG.

Two challenges facing the world: population growth and aging

In recent years, population growth and aging have been cited as two major global social challenges.

Population growth

According to the World Population Report, the global population, which reached 6 billion in 1999, surpassed 8.1 billion in 2024, increasing by 2.1 billion in just 25 years. Furthermore, United Nations projections indicate it will reach 10.3 billion by the mid-2080s, with population growth expected to continue.

Africa is one region experiencing rapid population growth, yet it also faces the problem of extremely high infant mortality rates. According to UNICEF research, 56% of global under-five deaths occur in sub-Saharan Africa, where 69 children per 1,000 births die before reaching age five.In high-income countries, the under-five mortality rate averages 4.9 deaths per 1,000 live births, highlighting a significant disparity.

The leading causes of death among children under five are pneumonia, malaria, and diarrhea, and an adequate supply of essential pharmaceuticals could help reduce these mortality rates.

Aging

In 1950, the proportion of people aged 65 older worldwide was 5.1%. By 2020, this had risen to 9.4%. Furthermore, it is projected to increase to 18.7% by 2060, ushering in an unprecedented aging society.

In Japan, the number of patients with lifestyle-related diseases such as diabetes and hypertension is increasing against the backdrop of an aging population. Since the risk of developing lifestyle-related diseases is higher among the elderly, demand for chronic disease treatments and medical services is expected to grow alongside the aging population.

Emergence of groundbreaking new drugs

For diseases where effective drugs have been limited until now, pharmaceuticals with superior efficacy to conventional treatments have been developed, raising expectations for these medicines higher than ever before. Examples of drugs developed in recent years are shown below.

● COVID-19 mRNA vaccine

● Anti-obesity drugs (GLP-1 receptor agonists)

● Alzheimer's disease treatment

● Gene therapy drugs

For pharmaceuticals requiring efficient administration, such as anti-obesity drugs, new types of medical devices (instruments) like pre-filled syringes and syringe cartridges—pre-filled with medication—are being adopted, as mentioned earlier. Glass tubing is used in these pharmaceutical containers. Furthermore, in emerging nations, alongside population growth, economic development is progressing, raising concerns about an increase in patients with lifestyle-related diseases. Consequently, an expansion in pharmaceutical demand is anticipated.

Against this backdrop, demand for materials used in medical devices, including glass tubing for pharmaceutical containers, is expected to continue growing.

Glass containers supporting pharmaceuticals

Pharmaceuticals may have their efficacy or safety compromised due to even trace impurities or leachables from containers. As containers are primary packaging materials that come into direct contact with the drug substance, it is essential that they do not react with the contents.

Containers for pharmaceuticals typically utilize materials such as plastics or glass. Plastic containers are lightweight and inexpensive, but they are relatively permeable to moisture and gases and have a higher potential for reacting with drugs, making them unsuitable for certain types of medications. On the other hand, glass offers high chemical stability and can preserve drug quality over long periods, making it a long-trusted material for containers, particularly for injectables where high safety is paramount.

What is borosilicate glass?

Pharmaceutical containers use borosilicate glass, a special type of glass, rather than common soda-lime glass. Borosilicate glass is suitable for pharmaceutical containers due to the following characteristics:

● Heat resistance (low thermal expansion coefficient)

● Chemical resistance (chemical stability)

● High Transparency

Borosilicate glass has a low thermal expansion coefficient, making it highly resistant to thermal shock caused by temperature differences. It withstands high-temperature sterilization and repeated freezing/thawing cycles, and is less prone to breakage.

Furthermore, due to its high chemical stability and excellent hydrolysis resistance (resistance to water), which is a key indicator for evaluating the suitability of pharmaceutical containers, it can be used for various drugs.

Borosilicate glass also boasts high transparency, enabling the proper detection of foreign matter or discoloration in pharmaceuticals prior to use.

Examples of Use in Medical Settings

Borosilicate glass is the material used for vials and ampoules, which are representative pharmaceutical containers, as well as for prefilled syringes and syringe cartridges, which are the current trend.

A vial is a small glass bottle used to store injectable medications such as vaccines. It is sealed with a rubber stopper, and when needed, the stopper is pierced with a syringe needle to withdraw the medication. Its key feature is that it allows withdrawal of only the required amount using a syringe, enabling it to be used multiple times.

An ampoule is a container sealed by fusing the glass after filling it with medication, characterized by having all surfaces in direct contact with the medication made of glass. To open it during use, break off the neck of the ampoule.

Prefilled syringes are syringes that come pre-filled with medication. Unlike vials, they eliminate the need to draw the medication into the syringe, allowing for direct administration. This offers advantages such as preventing medical errors, reducing the risk of contamination, and ensuring accurate medication dosing. Their use has increased in recent years for vaccines and biopharmaceuticals.

Glass Tubing for Pharmaceutical Containers Supported by NEG

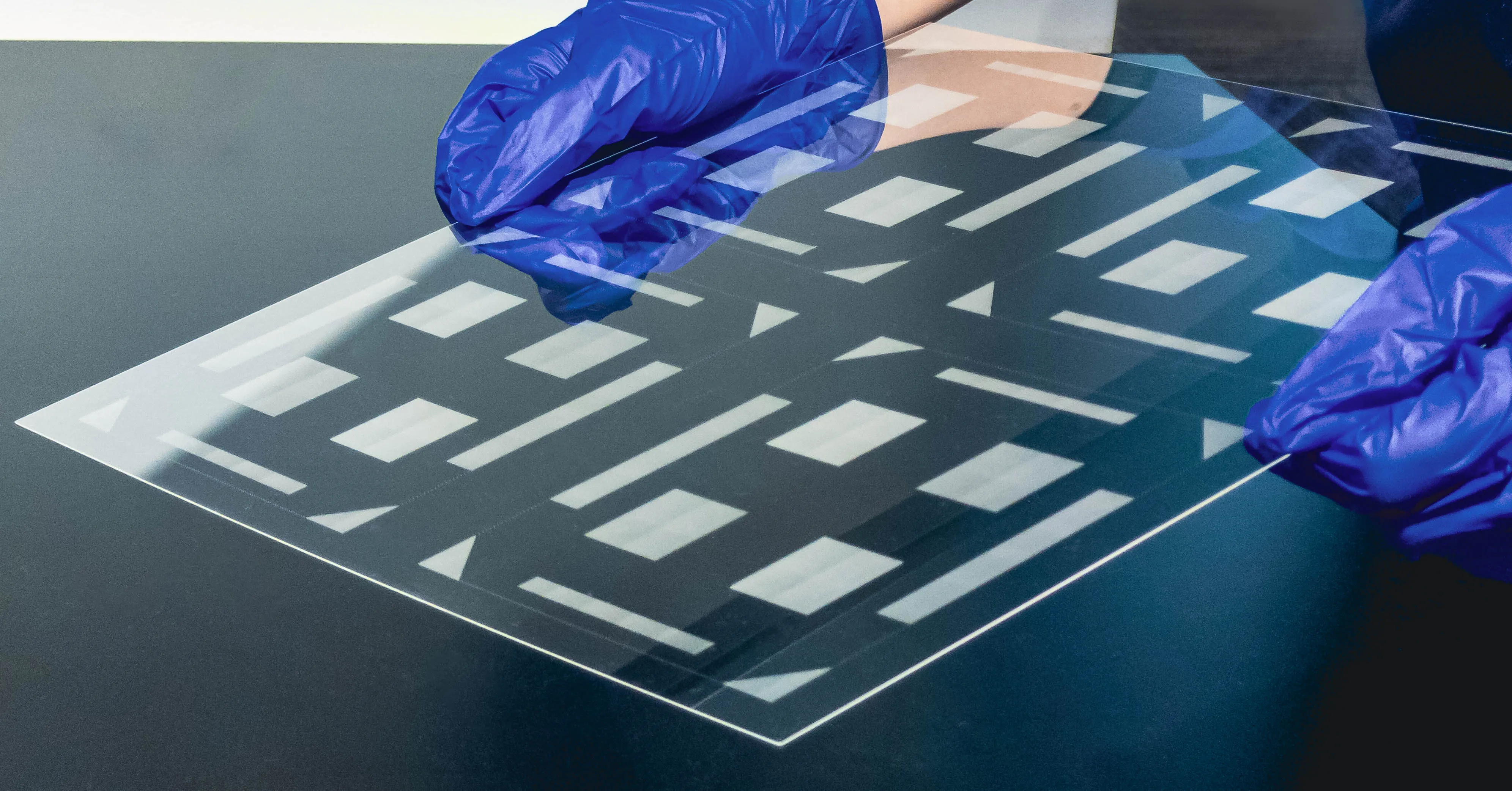

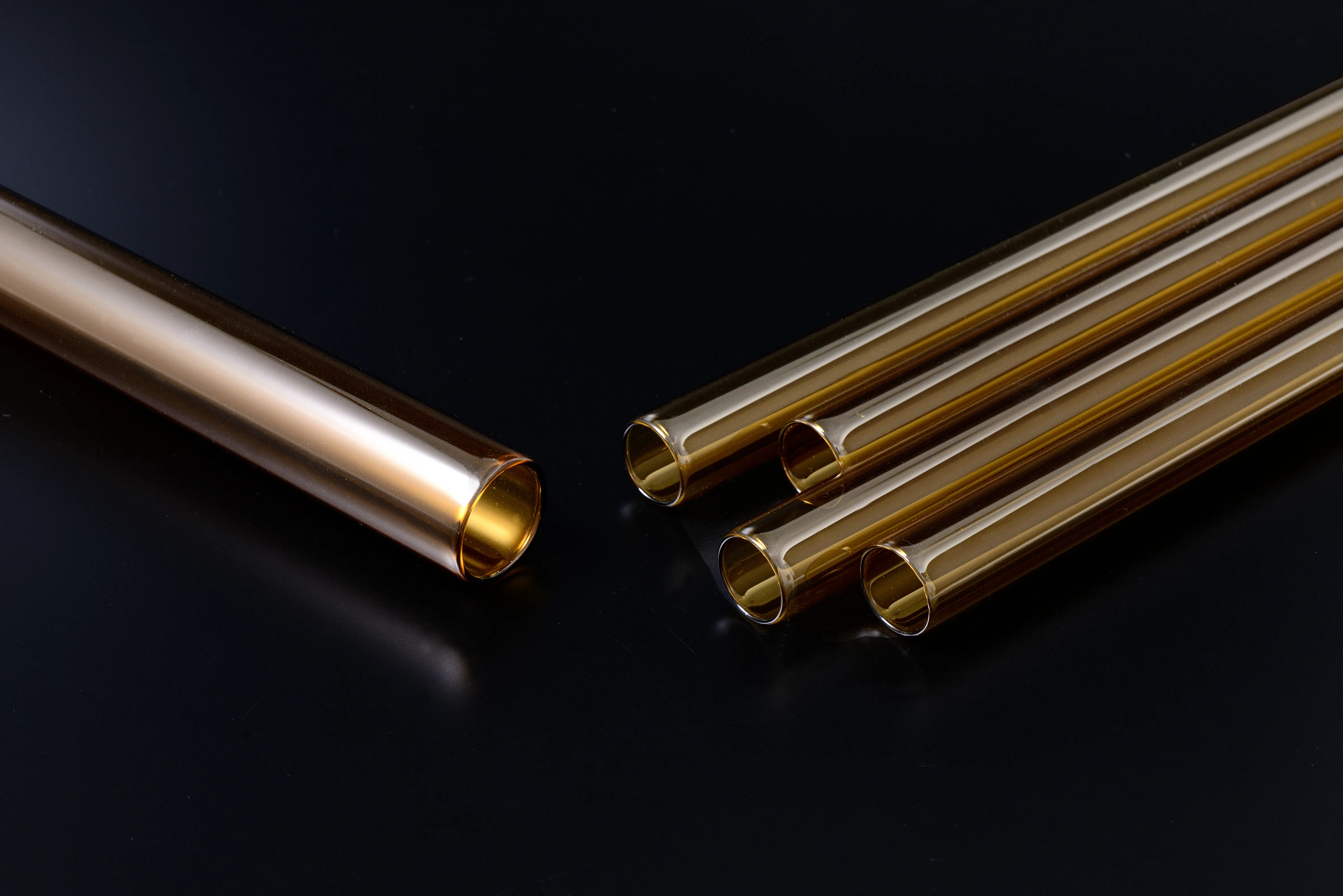

NEG manufactures borosilicate glass tubing for pharmaceutical containers. We supply "BS" and "BS-A" glass tubing for pharmaceutical containers that comply with Japanese, U.S., and European pharmacopoeias, continuing to support the foundation of medical infrastructure.

| Product Name | Features |

|---|---|

| BS | ・Colorless transparent borosilicate glass ・High chemical stability with minimal impact on pharmaceuticals |

| BS-A | ・Brownish-transparent borosilicate glass ・High chemical stability with minimal impact on pharmaceuticals ・Highly light-shielding, preventing degradation of agents caused by ultraviolet rays ・Highly visible, allowing visual inspection of the contents from outside the container |

Furthermore, the demand for high-quality pharmaceutical glass tubing is growing more than ever before due to new pharmaceuticals such as obesity drugs (GLP-1 receptor agonists) and changing market needs driven by the expansion of lifestyle-related diseases in emerging countries.

NEG possesses the technological capabilities to adapt to market changes, and will continue to meet the expectations of the healthcare industry and play a role in supporting the foundation of healthcare.

Summary

Due to two major societal challenges—population growth and aging—demand for pharmaceuticals is expected to expand. Furthermore, the emergence of unprecedented pharmaceuticals, such as mRNA vaccines for COVID-19, is also transforming medical devices and instruments.

Pharmaceutical containers primarily utilize borosilicate glass due to its excellent heat resistance, chemical resistance, and transparency. NEG has long manufactured and supplied "BS" and "BS-A," high-quality borosilicate glass tubing for pharmaceutical containers.

As we continue to anticipate the development of new pharmaceuticals and advances in medical technology, NEG will continue to support global healthcare through the supply of glass tubing for pharmaceutical containers.