Glass Manufacturing with Minimal Energy Leads to Higher Competitiveness

To solve the global issue of climate change, the Japanese government declared its commitment to achieving carbon neutrality with the aim of reducing the overall greenhouse gas emissions to zero by 2050. More than 120 countries and regions have set similar goals. Initiatives toward carbon neutrality have become a global challenge for companies to build a sustainable business model.

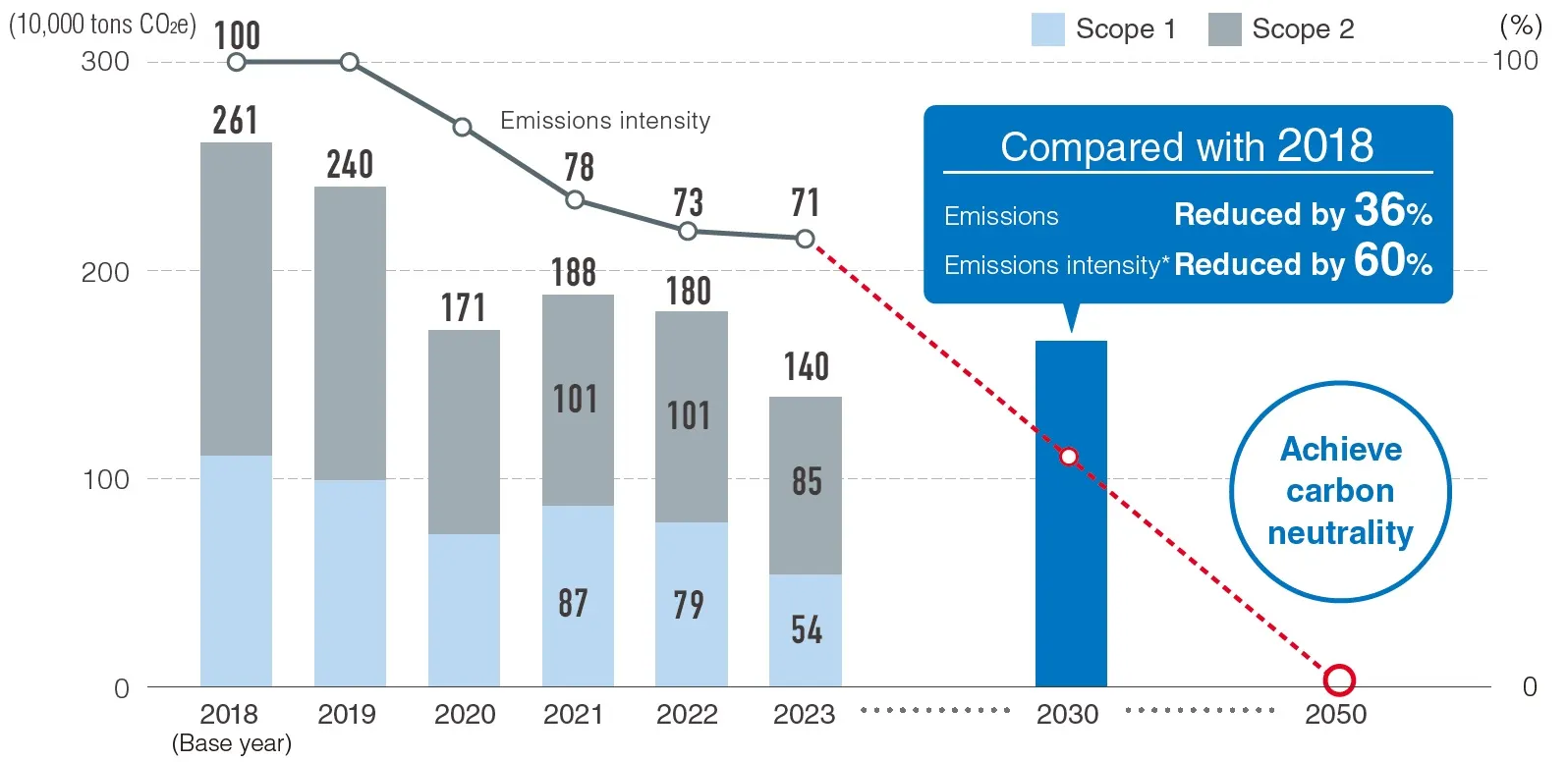

Nippon Electric Glass (NEG) has also been working on various initiatives to attain the goal of carbon neutrality by 2050 (announced in February 2022).

Scope 1 (direct emissions): Greenhouse gas emissions from assets directly controlled by a company

Scope 2 (indirect emissions): Indirect greenhouse gas emissions associated with the use of energy (mainly electricity) purchased by a company

We have pioneered environmental conservation with “consideration for the environment” as one of our key values. We interviewed Director and Senior Vice President (in charge of the environment) Hiroki Yamazakiand Senior Vice President (in charge of process engineering) Hitoshi Kanayaabout the background and efforts to attain carbon neutrality.

- Upsides and downsides of Japan’s high economic growth period

- Sustainable management starting in the 1970s

- Path to minimum input leading to carbon neutrality

- Switching to all-electric melting furnaces to make further progress

- Is it possible to completely switch to all-electric melting furnaces towards the 2050 target?

Upsides and downsides of Japan’s high economic growth period

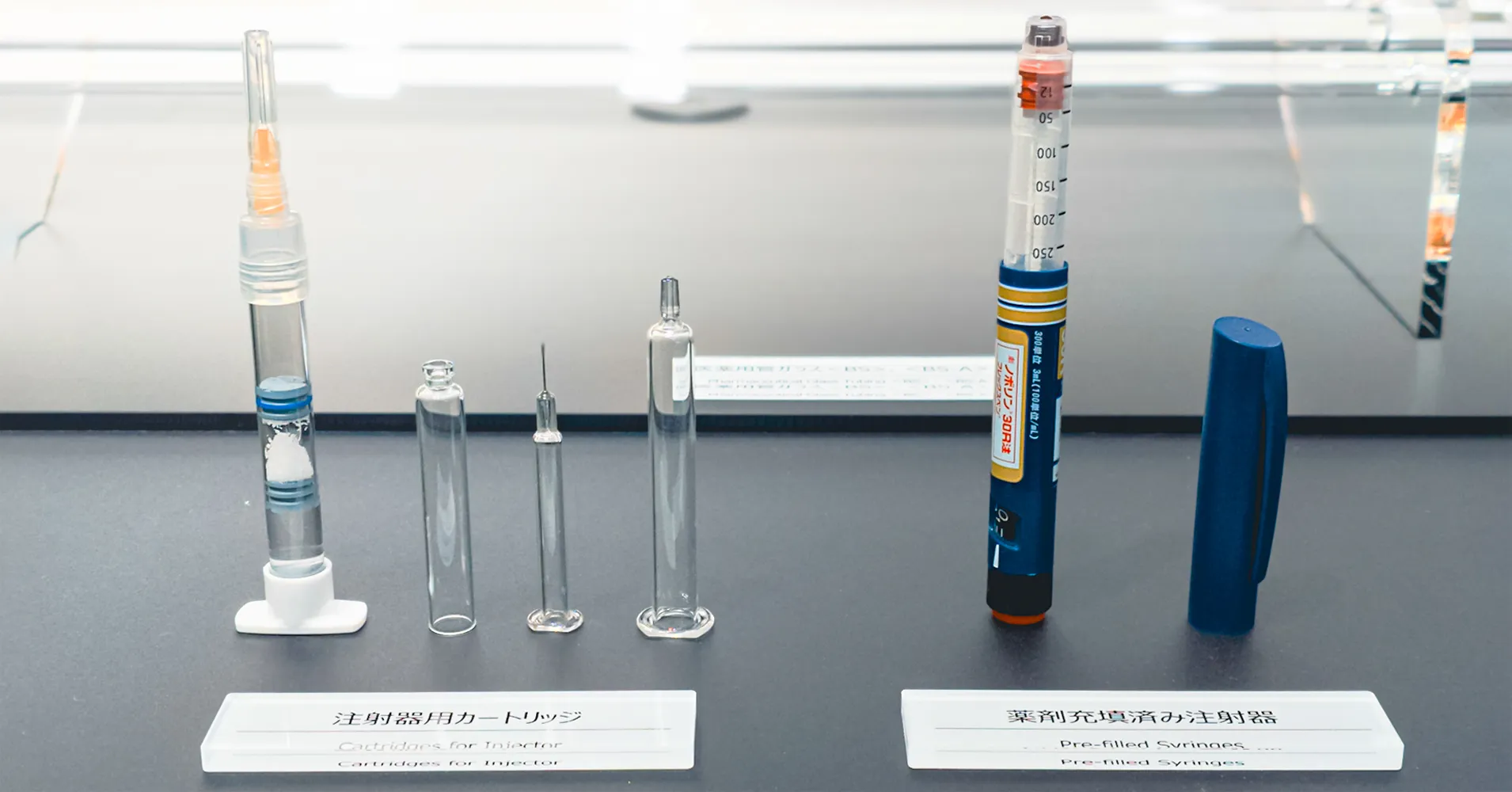

NEG was founded in 1949, when Japan was still experiencing post-war turmoil. Subsequently, Japan entered its high economic growth period from around 1955. While the economy grew and developed rapidly toward the early 1970s, pollution problems started to emerge in different areas of the country. NEG also has a bitter history of causing environmental problems.

Yamazaki: “Glass has a unique feature of exhibiting diverse functions through incorporating various elements. Previously, environmentally harmful substances and substances that have undesirable effects on the human body were also used to exhibit such functions. Typical examples included lead, fluorine, arsenic, and boron. In those days, top priority was placed on glass properties, and glass was manufactured actively using such substances, which were effective in allowing superb functions to be exhibited. Obviously, companies complied with environmental laws and regulations, which were far lenient than those enforced today. Corporate awareness about exhaust gas, wastewater, and waste matters was not high. Against this backdrop, companies polluted the surrounding environment contrary to their intention.

At that time, fluorine compounds contained in the exhaust gas from our Shiga-Takatsuki Plant affected mulberry leaves, which were used to feed silkworms kept by local farmers, and the silkworms stopped making cocoons. In addition, at the Fujisawa Plant (closed in 2015), a local resident movement developed, claiming that lead and fluorine used at the plant were polluting the surrounding environment. We had to stop half of the melting furnaces which were in operation at the Fujisawa Plant.”

Sustainable management starting in the 1970s

Source: 2nd issue of the “P&P” PR magazine on technology , published in 1976 by NEG.

Nowadays, all companies focus on business operations to minimize the environmental impact. Based on its bitter experiences, NEG became a pioneer in launching a sustainable management initiative in the 1970s

Yamazaki: “The president at that time (Junichi Nagasaki, the third president and de facto founder) stated that the company would not survive if the management complied with the environmental rules haphazardly. He provided firm instructions to introduce equipment necessary to realize efficient production with minimal raw materials, water, and energy (minimum input) and minimize the discharge of environmentally harmful substances to the external environment (minimum output), even if it incurred some extra costs.”

If the waste polishing material (sludge) generated during the glass polishing process is re-used without any treatment, it will discolor the glass products.

To continue business in Shiga Prefecture, a nature-rich area where NEG’s main operations are located, collaboration with local residents is an extremely important issue. NEG has persistently worked to minimize the impact on the surrounding environment to a level satisfactory to local residents.

Yamazaki: “As I mentioned earlier, we have made consistent efforts since the 1970s to minimize both input and output. With “the SDGs” coming into focus in recent years, the efforts that we have taken for granted have become a hot topic in society. Apparently, our decades-long efforts may seem to be foresighted, but it is nothing new for us.”

Yamazaki: “Let me take waste matters as an example. In the manufacture of glass, most by-products are originally contained in the glass raw materials. If impurities are removed, the by-products can be reused as glass raw materials. For example, if waste polishing materials (sludge) generated during the glass polishing process is reused without any treatment, it will discolor the glass product. They can be used as glass raw materials if the iron content is removed. This helps reduce the consumption of natural raw materials. The dust contained in exhaust gas can also be recycled as a glass raw material if it is collected and treated properly. Being highly aware of such characteristics of glass, Mr. Nagasaki, the then president of NEG, was strongly committed to recovering glass raw materials, even if the process required time and cost, at a time when such recycling was not practiced actively and widely. Since then, we have made steady efforts along these lines.”

Decades of proactive commitment to thorough recycling of waste and exhaust gas has made the company what it is today.

Path to minimum input leading to carbon neutrality

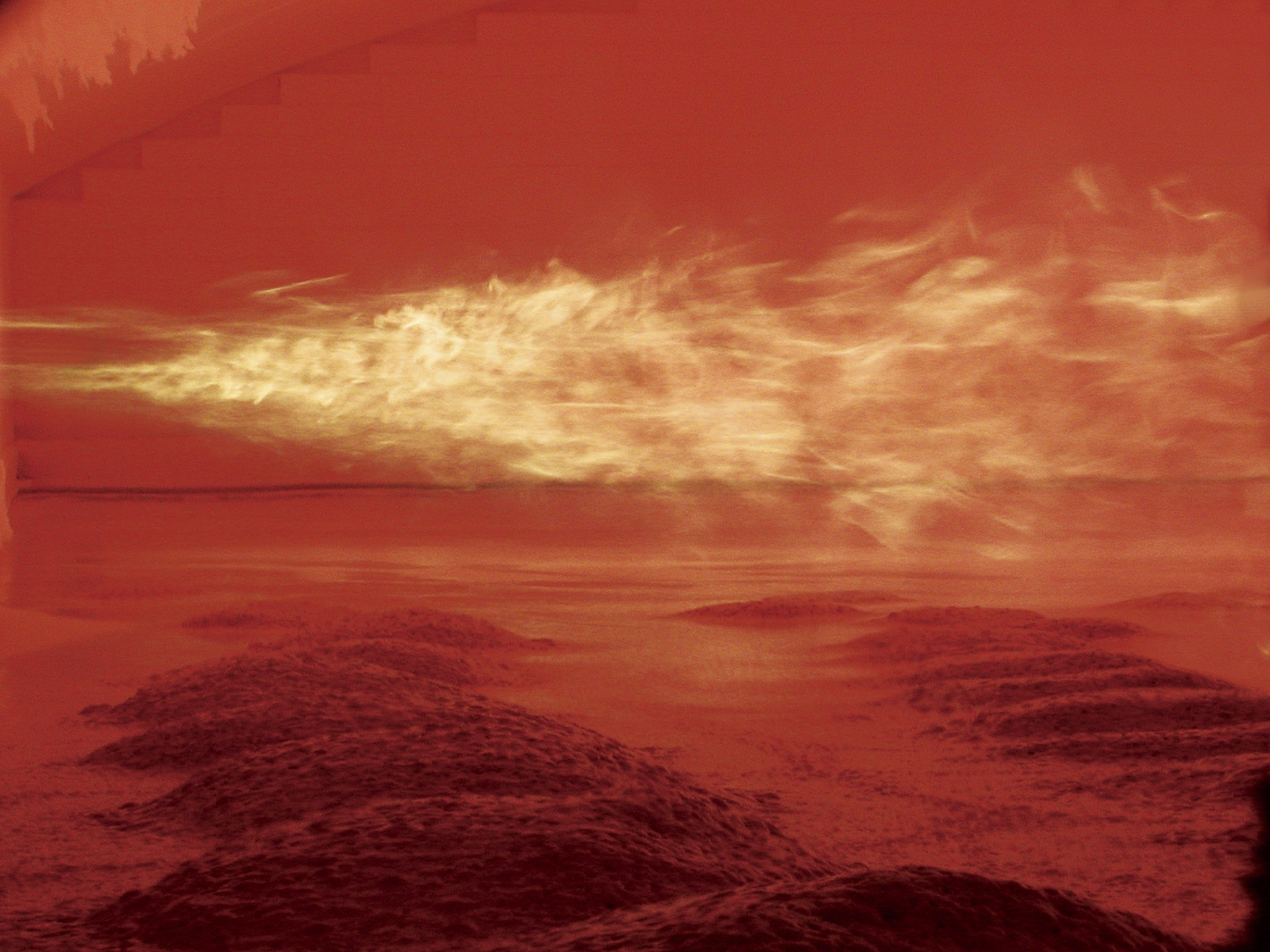

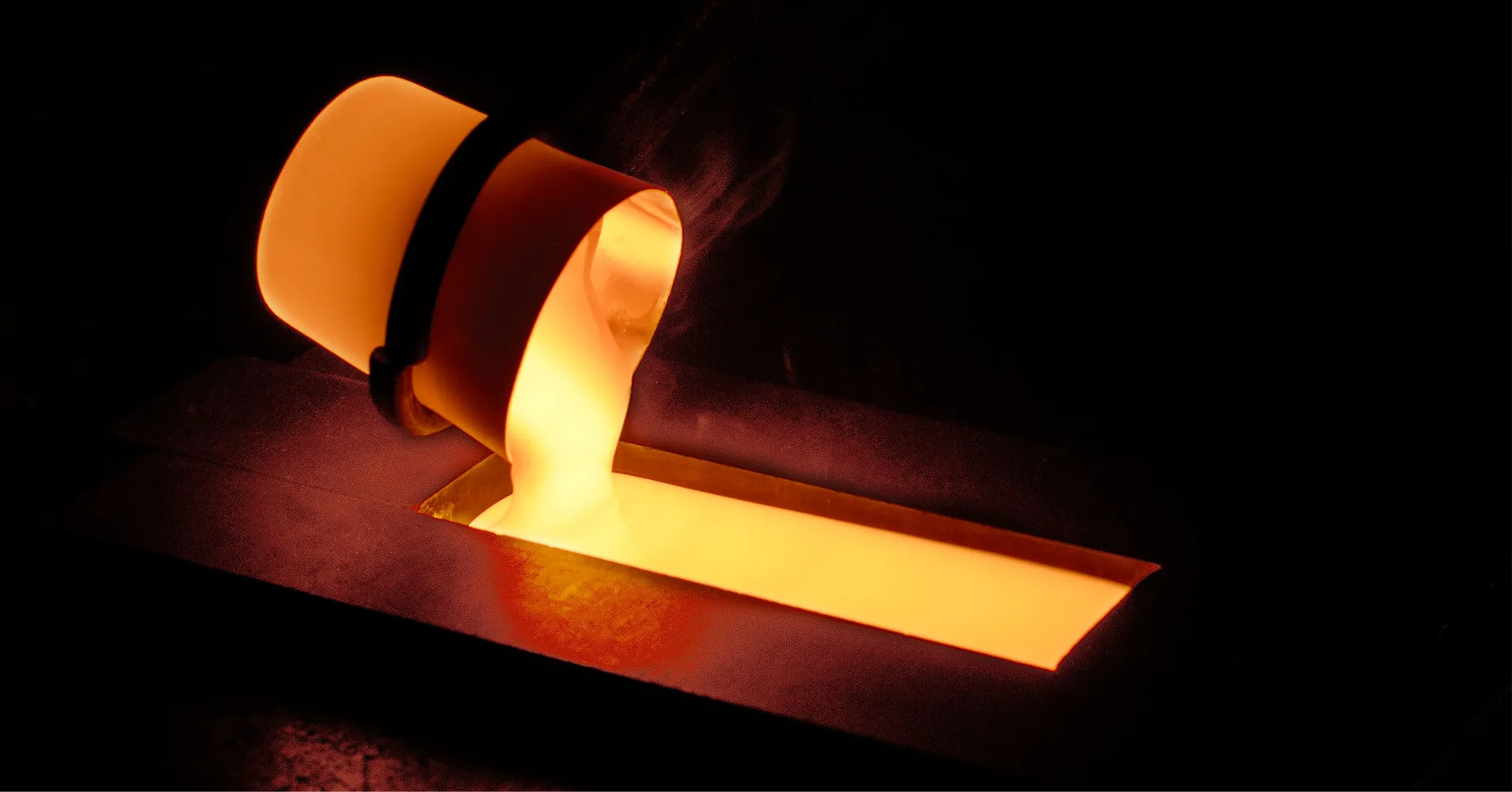

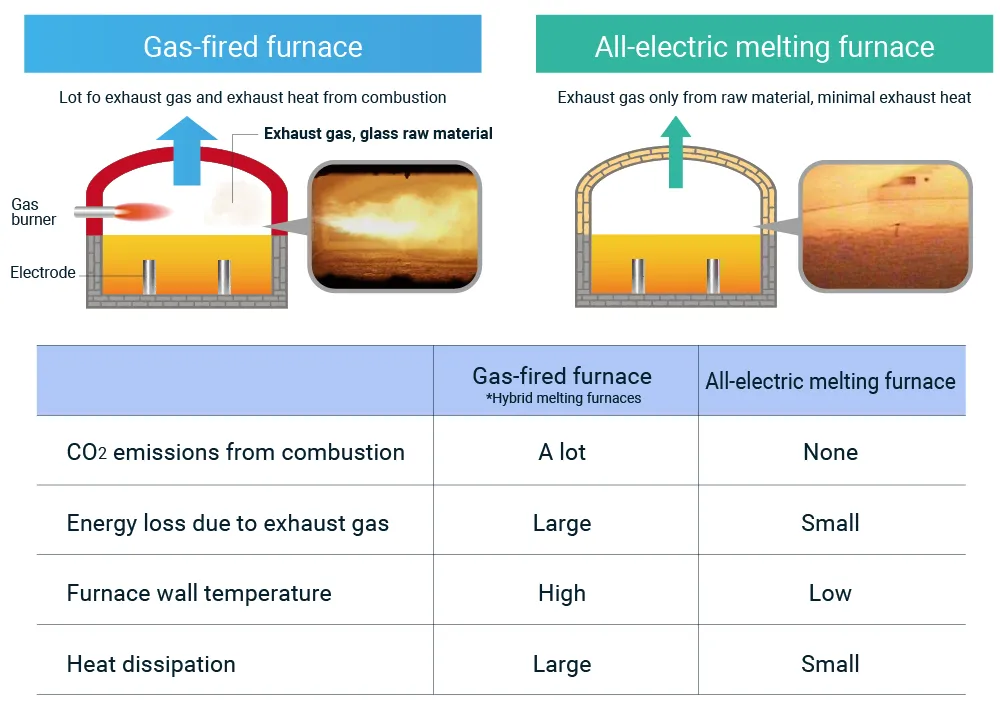

A lot of energy is required in the manufacture of glass, particularly in the process of melting raw materials into glass. Thus, reduction of greenhouse gas emissions from melting furnaces is an important issue.

The key is an initiative to improve energy efficiency and reduce CO₂ emissions from the melting process. NEG has actively implemented the three specific measures below:

-

Introduction of oxy-fuel firing furnaces

-

Fuel conversion in melting furnaces

-

Increase in the ratio of electricity used for the melting energy

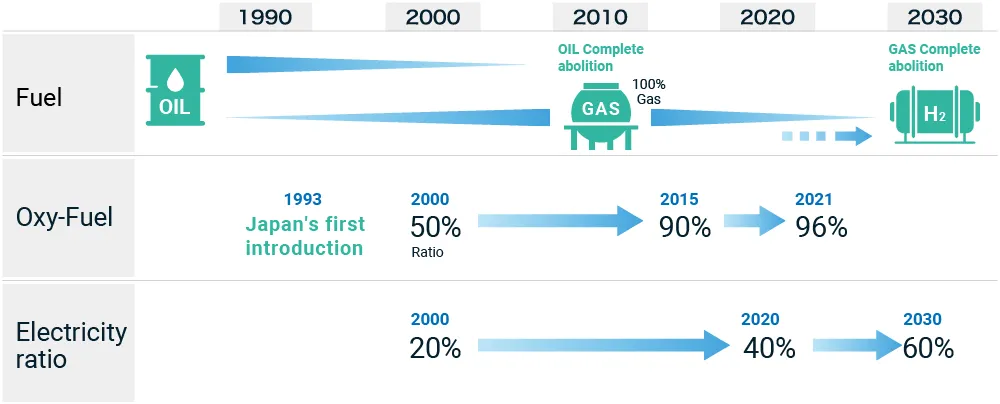

1. An oxy-fuel firing furnace refers to a system which uses oxygen instead of air for combustion of fuel. We became the first company in Japan to introduce such a furnace in 1993, achieving reductions in energy consumption, and emissions of CO₂ and nitrogen oxides (thermal NOx).

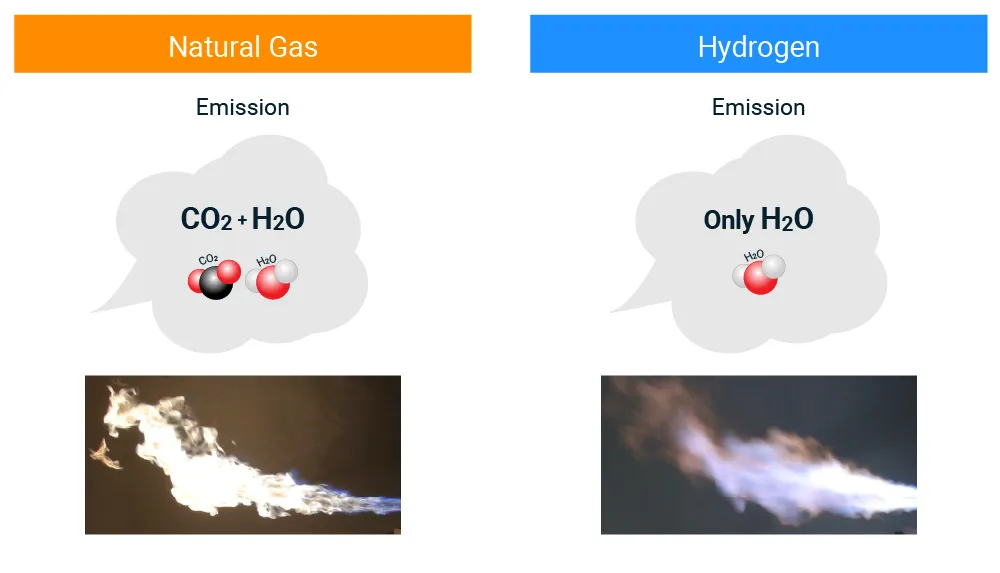

2. Regarding fuel conversion in melting furnaces, we switched from heavy oil, which was used for many years, to natural gas, whose CO₂ emissions are low. We have completed this switch in all of our melting furnaces.

3. Regarding an increase in the electricity ratio, we have significantly improved heat transfer efficiency by inserting electrodes into the melting furnaces and directly applying electricity to heat the glass, making it possible to reduce the energy consumption.

Yamazaki: “For example, when heavy oil is used as fuel for melting glass, SOx (sulfur oxide), which causes air pollution, is generated in addition to CO₂. Through complete abolition of the use of heavy oil in FY2010, NEG significantly reduced the emission of air pollutants in addition to a reduction of CO₂ emissions. In a conventional air firing system, nitrogen gas, which makes up about 70% of air, does not contribute to combustion. It is heated in a melting furnace and carries heat, which is valuable energy, out of the furnace. In the oxy-fuel firing system, nitrogen is not brought into the furnace. This significantly improves energy efficiency and reduces NOx, which is generated by heating nitrogen and causes air pollution. At present, we promote the development of a hydrogen-fuel firing system as an advanced technology which does not generate CO₂ during combustion. Such ongoing efforts have made it possible to reduce CO₂ emissions year after year.”

However, it was pointless to focus too much on the environmental aspect and make our products less competitive.

Yamazaki: “If we aim to manufacture glass with minimal energy, the manufacturing cost will inevitably decrease, and CO₂ emissions can be reduced. Our manufacturing operations focusing on minimum input have improved the competitiveness of our products and have contributed to carbon neutrality.”

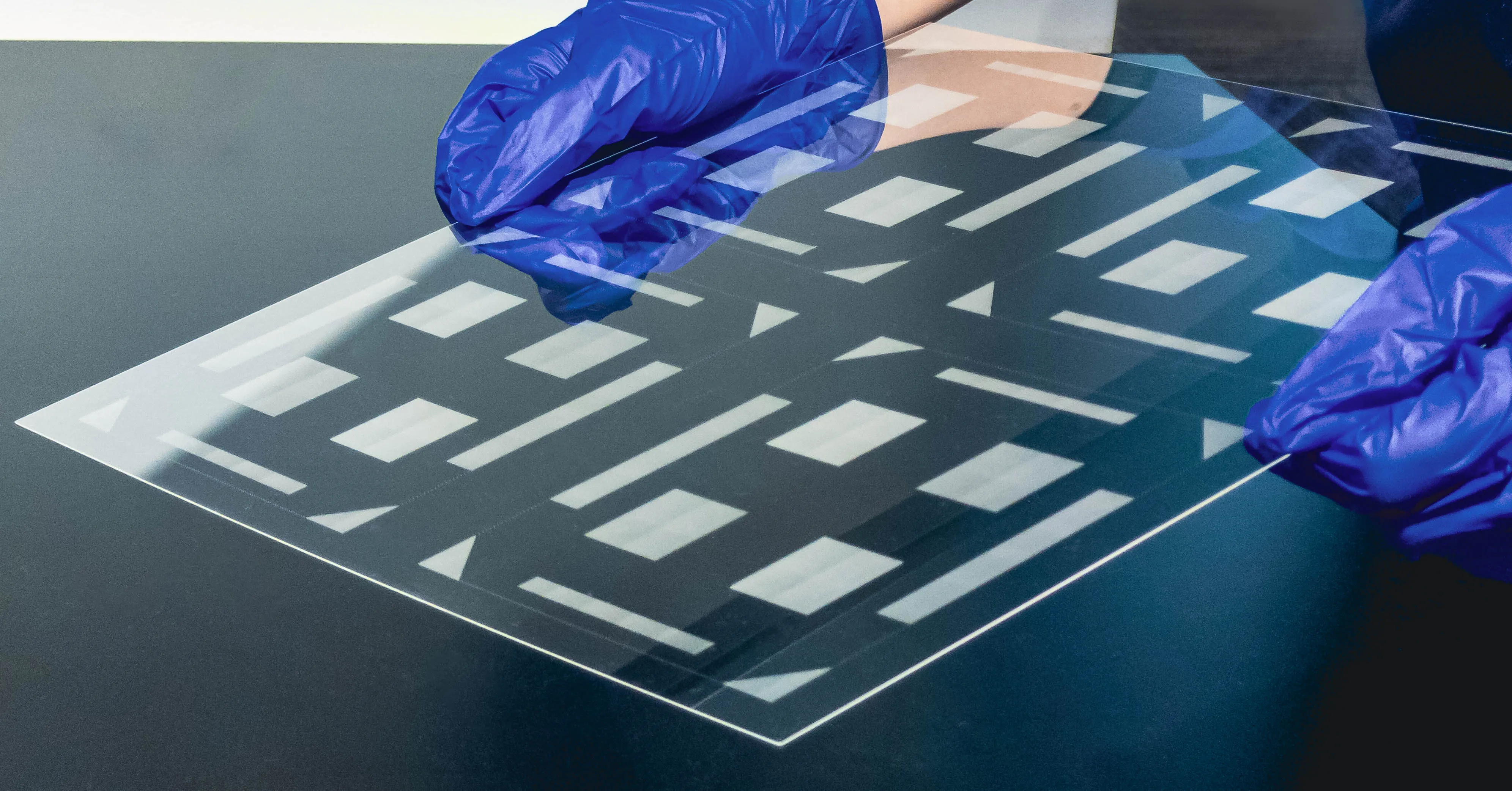

Based on the belief that the most efficient manufacturing in the world will lead to the most environmentally friendly manufacturing in the world, NEG practices sustainable manufacturing to save energy and reduce its CO₂ emissions through improving quality and pursuing higher manufacturing yield.

Switching to all-electric melting furnaces to make further progress

As mentioned above, NEG has actively deployed hybrid melting furnaces, which combine indirect heating through oxy-fuel firing using natural gas and direct electrical heating to directly apply electricity to glass using electrodes inserted into the melting furnaces. As a further advanced approach, we are currently promoting conversion to all-electric melting furnaces, which use only electricity to supply the energy required for melting. As of 2023, the ratio of electricity introduced to our group reached 39%. We will continue to actively promote conversion.

Yamazaki: “NEG was among the first in the industry to introduce all-electric melting furnaces, which basically use only electricity as the energy required for melting glass, in 1974. Because they do not burn fuel, such as heavy oil and gas, they do not generate exhaust gas or noise from combustion. There are issues to be addressed, but all-electric melting is a key technology for realizing carbon neutrality.

Previously, the types of glass suitable for all-electric melting were limited, and the technology was still immature. The cost was not as low as that of gas-firing furnaces. Thus, we continued research on a small scale. Over the past 10 years or so, there have been dramatic advances in peripheral technologies, including simulation technology for estimating the flow of molten glass inside a melting furnace, making it possible to deploy all-electric melting technology on a full scale.

We did not make a haphazard decision to promote all-electric melting to realize carbon neutrality in response to the growing public awareness of carbon neutrality. Our decades of steady efforts to minimize inputs and outputs were just fit with the movement of the times.”

Is it possible to completely switch to all-electric melting furnaces towards the 2050 target?

At NEG, the initiative to switch to all-electric melting furnaces is well underway, but there are still hurdles to overcome.

At present, this method is not suitable for all types of glass and production scales.

Kanaya: “We aim to switch entirely to all-electric melting furnaces in the future, but at the present, this method is not applicable all types of glass and production scales. All-electric melting is fine for simply melting raw materials, but the story is different when it comes to production that meets the required quality and cost. We aim to efficiently manufacture glass of a higher quality than that of our competitors’ products at an even lower cost while pursuing the goal of carbon neutrality. All-electric melting is the technology to make this happen.

Until the furnaces are entirely replaced by all-electric melting furnaces, what action do you take in areas where you must rely on combustion?

Kanaya: “As mentioned earlier, in areas where we must rely on combustion, we have been developing technologies that do not emit CO₂ during combustion. In FY2022, we developed a hydrogen-oxy-combustion burner, which uses 100% hydrogen as fuel, and succeeded in a glass melting demonstration experiment.”

NEG has also been working to reduce CO₂ emissions by using renewable energy for part of the electricity it uses. For example, we installed a large-scale solar power generation system (estimated capacity of about 3.7 GWh/year) at the Shiga-Takatsuki Plant. It came into full-scale operation in April 2023.

Based on the firm belief that the most efficient manufacturing in the world will lead to the most environmentally friendly manufacturing in the world, NEG is committed to ensuring efficient use of energy and reducing waste. In FY2023, we reduced our unit energy consumption* by 21% compared to the 2018 level. NEG’s consistent sustainability management efforts since the 1970s with the aim of minimizing both input and output have been stepped up toward the goal of realizing carbon neutrality by 2050. Specific initiatives and various data are published in the Integrated Report and ESG Data Book on the Sustainability page of our website. Please explore the documents for further insights.

-

● Unit energy consumption*: Energy consumption required for the production of products per unit weight