Leading the World with Special Glass — Core Identity of Nippon Electric Glass —

What do you associate with “glass”? It may be a window, a bottle, or tableware.

While glass is a familiar product, do you know about “special glass,” which is completely different from the general image we have of glass?

Some products are thinner than paper and can be flexibly bent or rolled. Others include glass fibers, which are thinner than a human hair and are used to reinforce automotive parts and materials as well as building materials. The more you learn, the more you will be amazed by special glass, which is characterized by unique shapes, properties, and functions. This article introduces Nippon Electric Glass Co., Ltd. (or “NEG”), a leading company of special glass.

Nippon Electric Glass, in pursuit of “the unlimited possibilities of glass”

Glass, a material which has accompanied the progress of humankind

The origin of glass is unknown, but its history dates back as far as 4500 BC. Glass is considered to have been made in the ancient Orient. In Japan, imported glass was processed as early as the Yayoi period (c. 300 BC to 300 AD) (Source: website of the Glass Manufacturers’ Association of Japan).

Glass has accompanied the progress of humankind as “a material with a history of 7,000 years.” It has unique features as a material which underpins the development of modern society and industry.

-

Almost all the elements in the world can be incorporated into glass to impart various properties.

-

Functions, properties, and shapes which meet various needs can be imparted to glass through melting, forming, and processing.

Birth of special glass

From ancient times, glass was used for accessories, containers, and windows. Glass has evolved rapidly in line with innovations in industry as well as science and technology. Today, the field of special glass has been expanding in response to the advancing needs of society and industry.

Special glass is different from the general image of glass, such as being hard, heavy, and fragile. It has excellent properties, including heat resistance and strength. Its shape also varies, including tubes, plates, sheets, rolls, fibers, powder, paste, spheres, lenses, and prisms. It is also available in varying sizes, ranging from glass fibers of a few micrometers in diameter to display glass substrates with sides exceeding three meters.

The scope of applications of special glass is truly unlimited, including display devices, information and communication, semiconductors, automobiles, medical care, energy, buildings, electric home appliances, household equipment, social infrastructure, and even outer space.

Under the mission to make life better and more comfortable for people and communities the world over using special glass, Nippon Electric Glass Co., Ltd. (NEG) is committed to manufacturing special glass in pursuit of “the unlimited possibilities of glass” as a leading global manufacturer.

- • A global company founded near Lake Biwa! Why NEG is a leading special glass company

- • Tracing the history of NEG

- • NEG opens up the future and possibilities of glass

- Glass thinner than copy paper and ribbon-shaped ultra-thin glass

- Dinorex™ for protecting smartphones, and Dinorex™ UTG designed for foldable displays

- An all-solid-state secondary battery made from glass! A hot technology which can be applied to EVs, outer space, and the deep sea

- A special glass technology indispensable for semiconductors now in the spotlight

- Glass-ceramics, which are used in our daily lives

- • The future of special glass envisioned by NEG?!

A global company founded near Lake Biwa! Why NEG is a leading special glass company

NEG is headquartered on the shores of Lake Biwa in Otsu City, Shiga Prefecture, and provides various types of special glass to customers around the world.

To date, NEG has produced hundreds of types of special glass products to constantly meet global needs. What drives NEG’s strength to make this possible?

NEG’s manufacturing

For decades, NEG has developed a wide range of glass technologies, including material design, melting, forming, processing, and evaluation, and has integrated these technologies into its equipment while developing new applied technologies. These technologies help produce unique, highly functional glass that meets the needs of the times and society.

NEG’s manufacturing is underpinned by the philosophy “to create products infused with the very best of human civilization.” They refer to products which benefit us as time passes and grow with the progress of civilization.

With this in mind, we constantly consider how we can create nice-to-have functions of glass sought by society and contribute to the realization of such products. While the functions needed by the progress of civilization change with the times, we aim to ensure that the special glass developed by us fulfills these needs and makes people’s lives better.

Tracing the history of NEG

Founding period

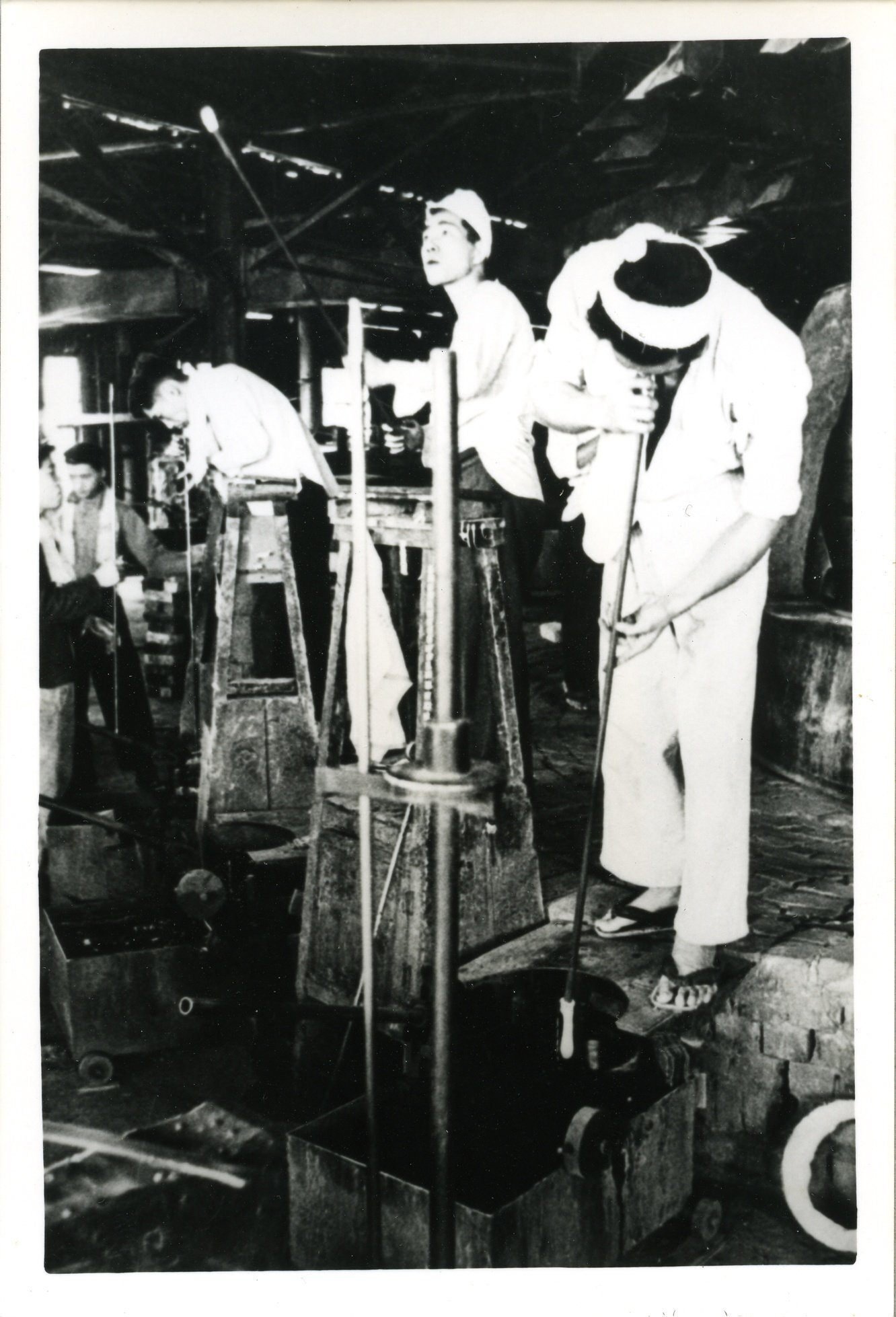

NEG’s history dates back to 1944 when the company was established with capital contributions mainly by NEC Corporation. It was spun off in 1949.

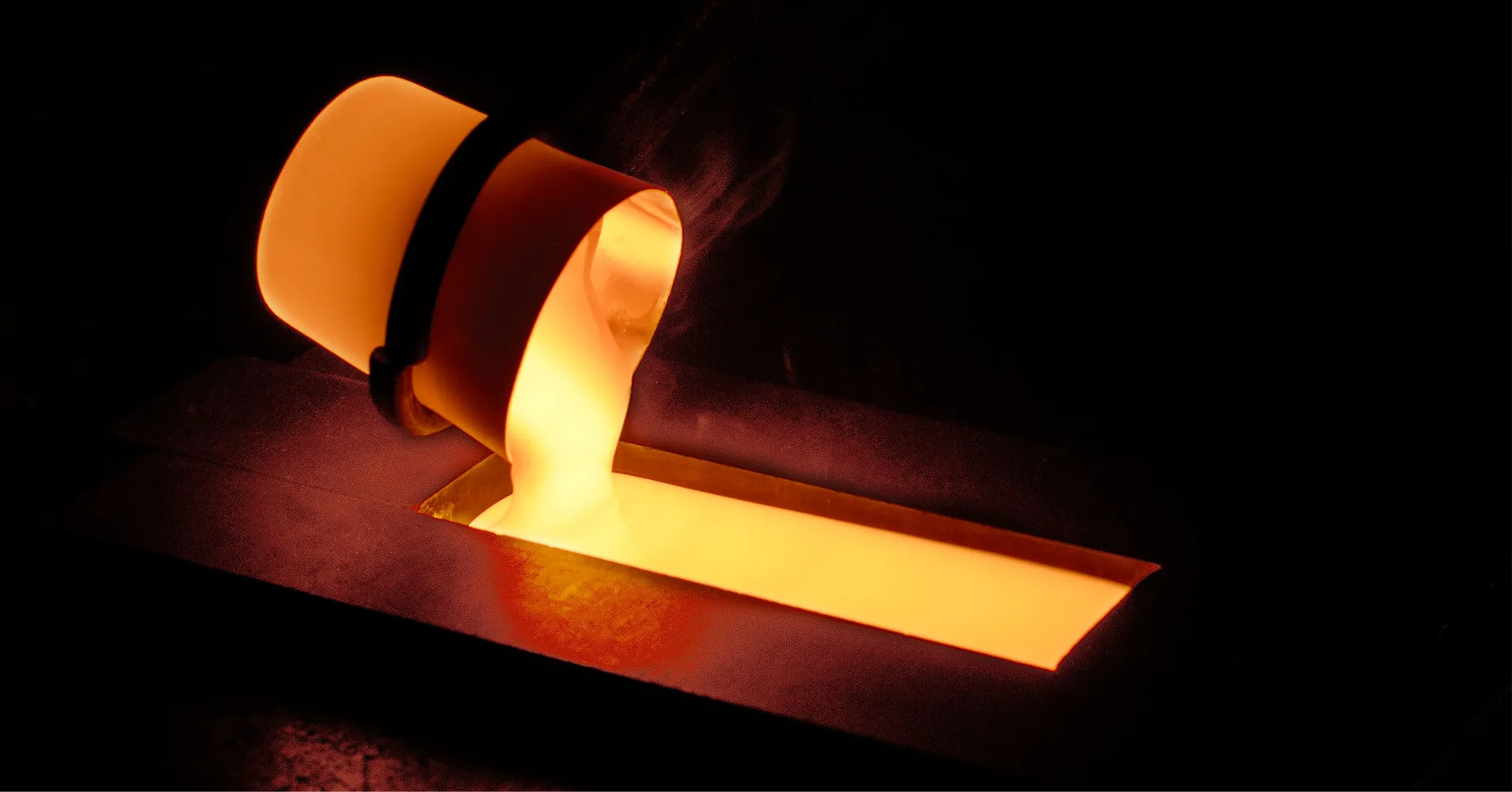

In the early days, glass for vacuum tubes and glass tubes was hand-blown, but we succeeded in automatic forming in 1951. We shifted to continuous production using tank furnaces in 1956, laying the foundation for our business expansion.

Era of CRTs

We entered the cathode ray tube (CRT) glass business in 1965. We grew in line with the development of the CRT industry, and our CRT glass business developed into our core business. Meanwhile, we launched many other businesses, including glass-ceramics, glass for buildings, electronics, and liquid crystal displays (LCDs), and glass fibers, achieving high growth to become a world-class special glass manufacturer.

Shift to FPDs

To meet the rapid growth of flat panel displays (FPDs), including LCDs, which became popular in place of CRTs in the latter half of the 1990s, we began production of LCD glass substrates based on a new manufacturing method known as the overflow process in 2000. Subsequently, we met ever-advancing market needs, including substrates of larger sizes and higher quality.

Today, our glass substrates are used for LCDs and organic EL (OLED) displays, which are used in many fields and applications, including large TVs, PCs, smartphones, in-vehicle displays, and digital signage. We hold one of the top three market shares in the world. This manufacturing technology has led to the development of ultra-thin glass and glass for chemical strengthening.

A new growth driver

In the 2010s, we acquired European and U.S. glass fiber businesses from U.S.-based PPG Industries. The composites business and the displays business became our two core businesses.

Aiming for further growth

In the 2020s, in addition to our existing products, we continue to develop unique special glass products one after another, such as glass with a zero CTE (coefficient of thermal expansion), 5G-related products, jewelry glass, all-solid-state sodium-ion secondary batteries, and glass-ceramic core substrates for next-generation semiconductor packages.

In 2024, we formulated the EGP2028, a new medium-term business plan, with the aim of realizing sustainable growth and enhancement of corporate value.

NEG opens up the future and possibilities of glass

— Is this really made from glass?! Special glass which breaks conventional wisdom —

We will now introduce some of NEG’s special glass products. They are unique and innovative products derived from NEG’s glass technology, which has been accumulated throughout our history of over 70 years.

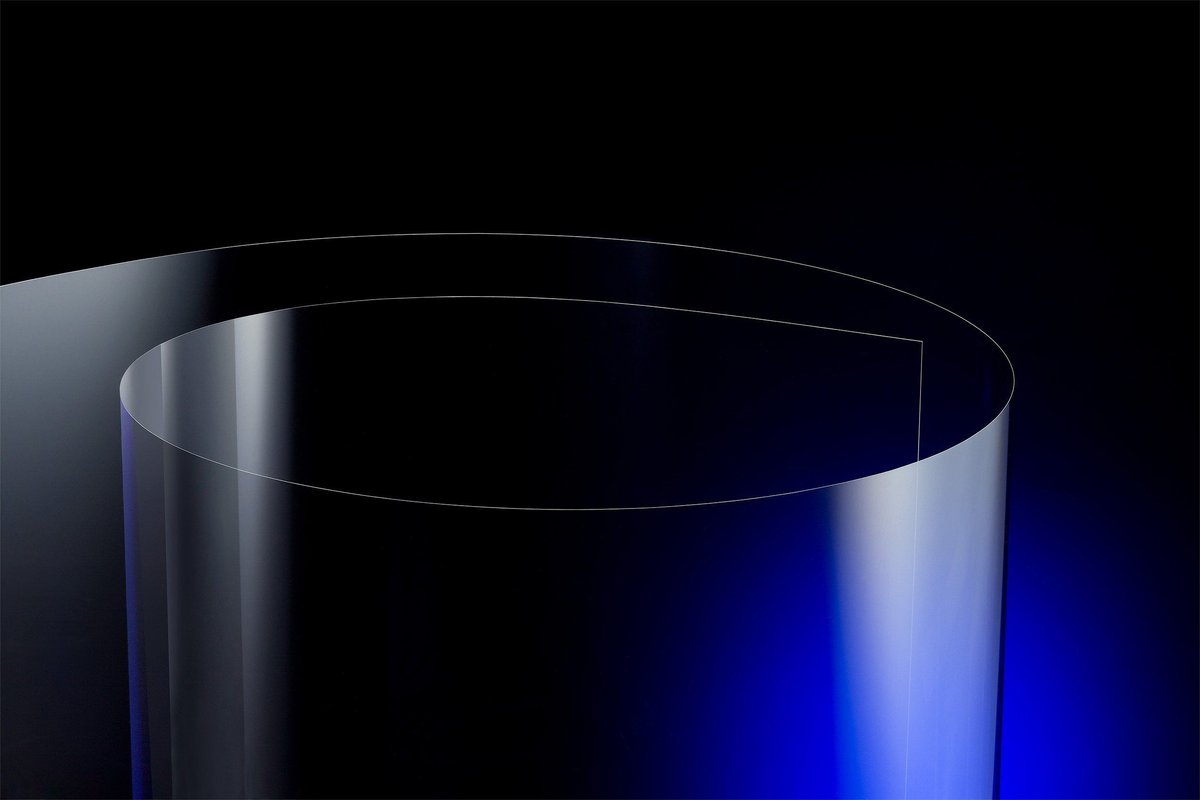

Glass thinner than copy paper and ribbon-shaped ultra-thin glass

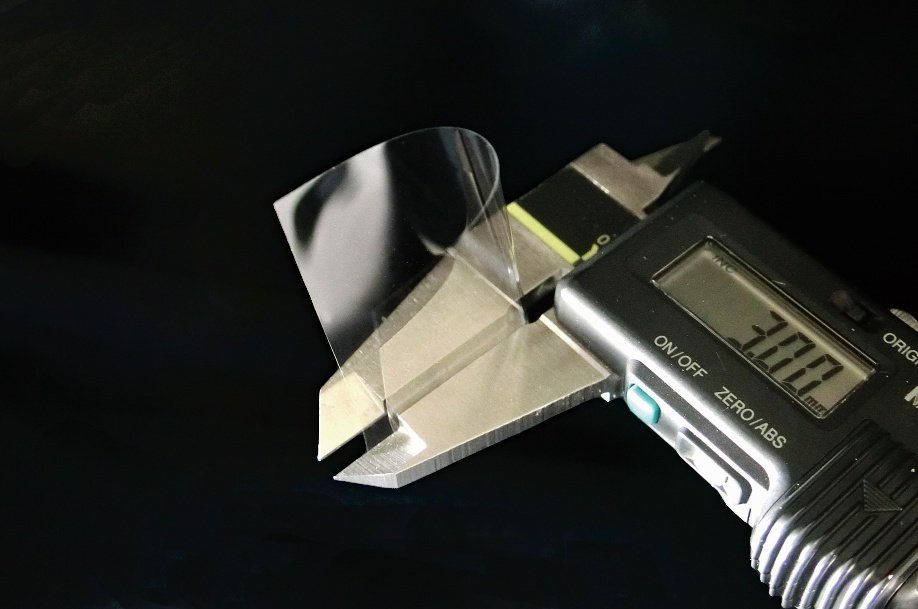

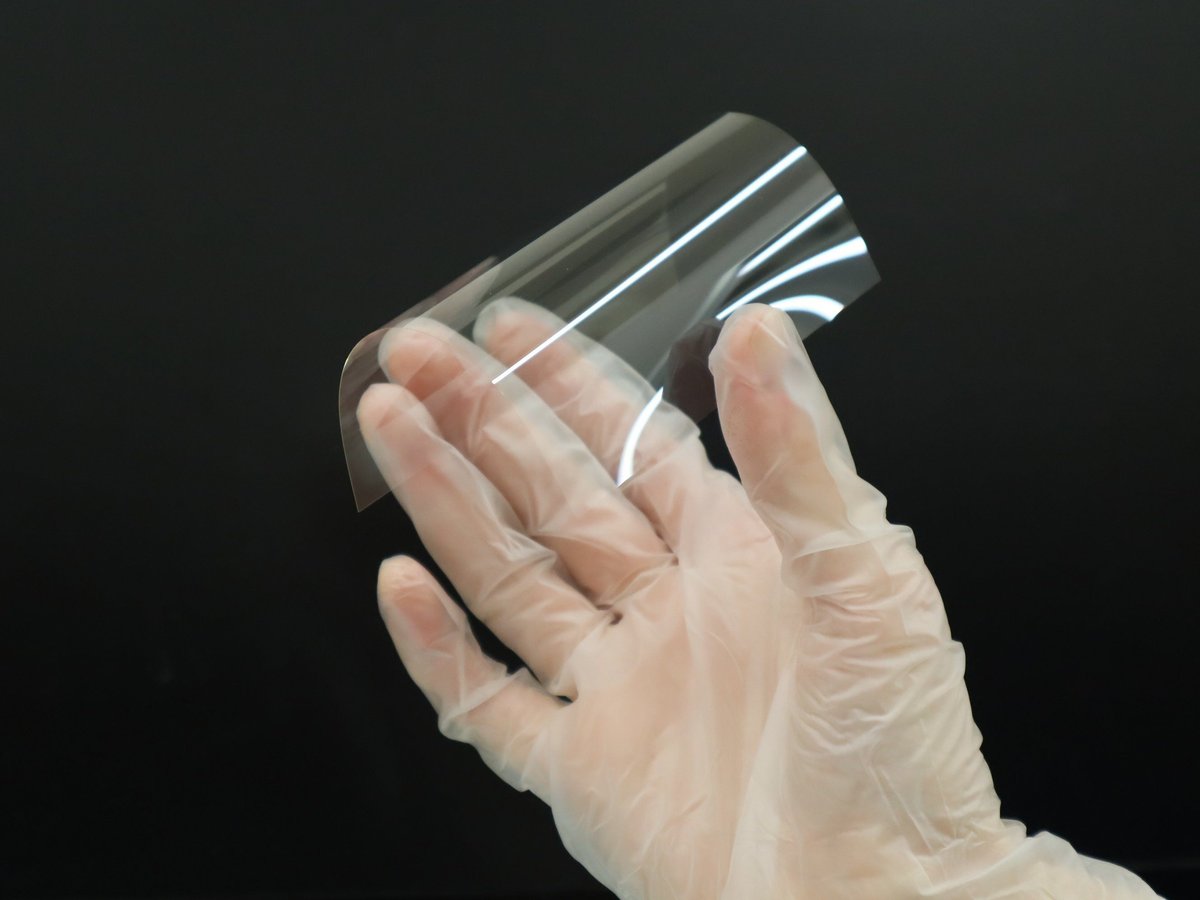

The first product you will be surprised to see is our G-Leaf™, film-like glass. NEG’s technology made it possible to reduce the thickness to 0.025 mm (25 μm), which is one third that of copy paper. We turned glass into film while retaining the excellent functionality and reliability of glass. It is expected to serve as a next-generation material in the electronics, energy, medical care, and lighting fields.

The thickness of a glass ribbon is only 4 µm. It is an excellent product that combines a highly flexible appearance while being thin, lightweight, and resistant to bending, and the unique properties of glass, such as heat resistance, durability, gas barrier properties that prevent the penetration of water and air, and chemical stability against chemicals.

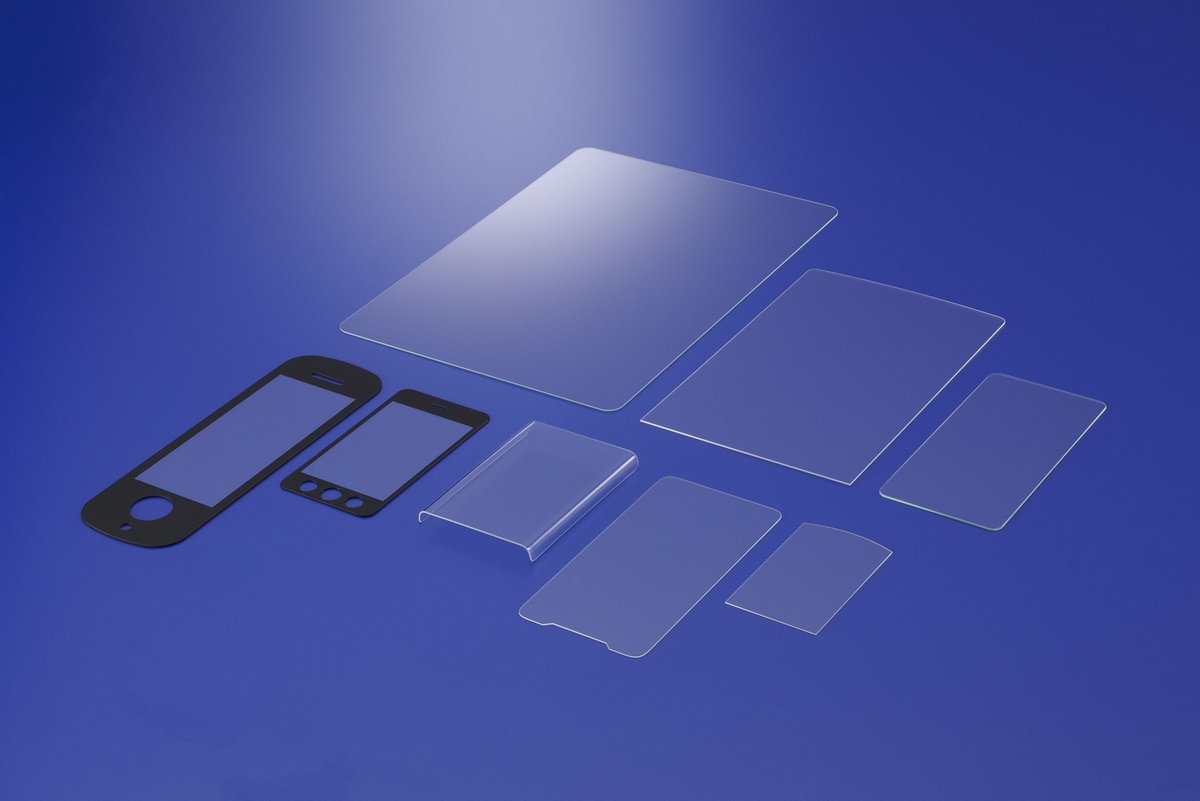

Dinorex™ for protecting smartphones, and Dinorex™ UTG designed for foldable displays

This is Dinorex™, glass for chemical strengthening, which is used for smartphones and tablets, as well as cover glass for in-vehicle displays and instrument clusters. It is tough enough to protect display screens from scratches and impacts.

Dinorex™ UTG, which further evolved from Dinorex™ and whose thickness is 25 μm, can be used for foldable displays. High surface smoothness and excellent bending properties enable bending to a diameter of 3 mm.

NEG’s special glass taken to space

NEG’s special glass is also used in the space industry. This is ultra-thin cover glass for satellite solar panels. The glass mitigates the deterioration of parts and materials of solar cells caused by ultraviolet rays in outer space and reduces the weight of the solar cells.

An all-solid-state secondary battery made from glass! A hot technology which can be applied to EVs, outer space, and the deep sea

NEG, which pursues both the unlimited possibilities of glass and the manufacturing of eco-friendly glass, has developed a cutting-edge battery that meets the needs of the times using special glass, “all-oxide solid-state sodium (Na)-ion secondary battery” (NIB).

The cathode, anode, and solid electrolyte of our NIBs are entirely made from stable oxides. They are firmly integrated by our proprietary glass-ceramics technology to form batteries. Our NIBs can operate even in severe environments (−40°C to 200°C) and do not pose the risk of ignition or generation of toxic gases. They are innovative all-solid-state batteries using sodium, an abundant material for which there are no concerns regarding resource availability.

A special glass technology indispensable for semiconductors now in the spotlight

Special glass is also expected to be used for next-generation semiconductor devices (related products).

In line with the growing demand for data centers and the increase in data traffic due to the spread of generative AI, semiconductors, which underpin the IT infrastructure, are required to realize even higher performance and lower power consumption.

To improve semiconductor performance, it is essential to develop technologies to increase processing speed through miniaturization of circuits and high-density mounting of multiple semiconductor chips on a single core substrate and to cope with larger substrates. However, miniaturization was difficult using conventional resin core substrates. The mounting of multiple semiconductor chips or an increase in the substrate size resulted in substrate deformation.

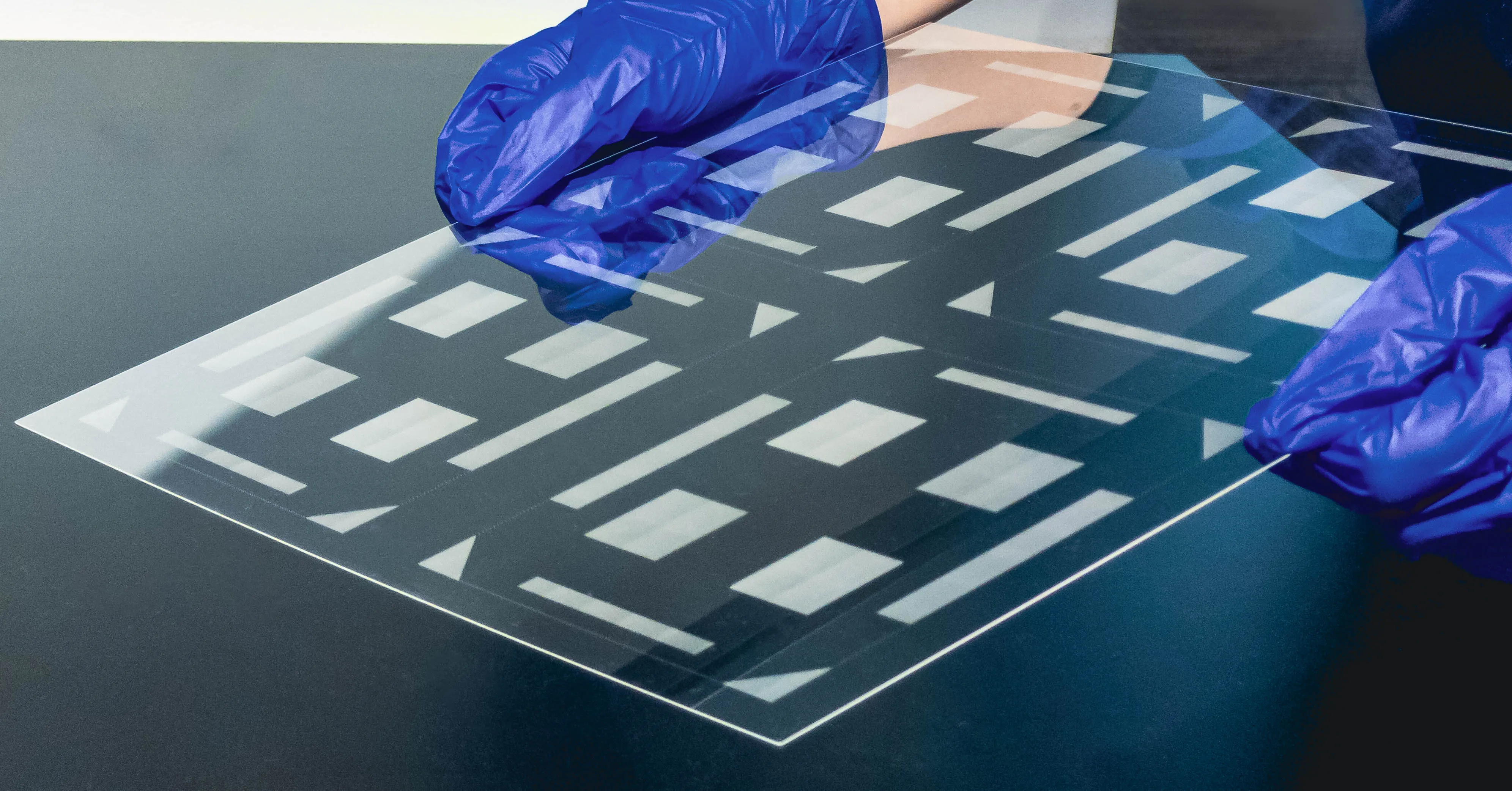

Thus, core substrates using glass, which is characterized by superb electrical properties, rigidity, and flatness, have been developed as next-generation materials.

GC Core™ developed by NEG is a core substrate using composites of glass powder and ceramic powder. In addition to the properties of glass core substrates, the new material also has the properties of ceramics, which are resistant to deformation and cracking, making it easy to realize high-speed, crack-free micro through-hole (via) processing.

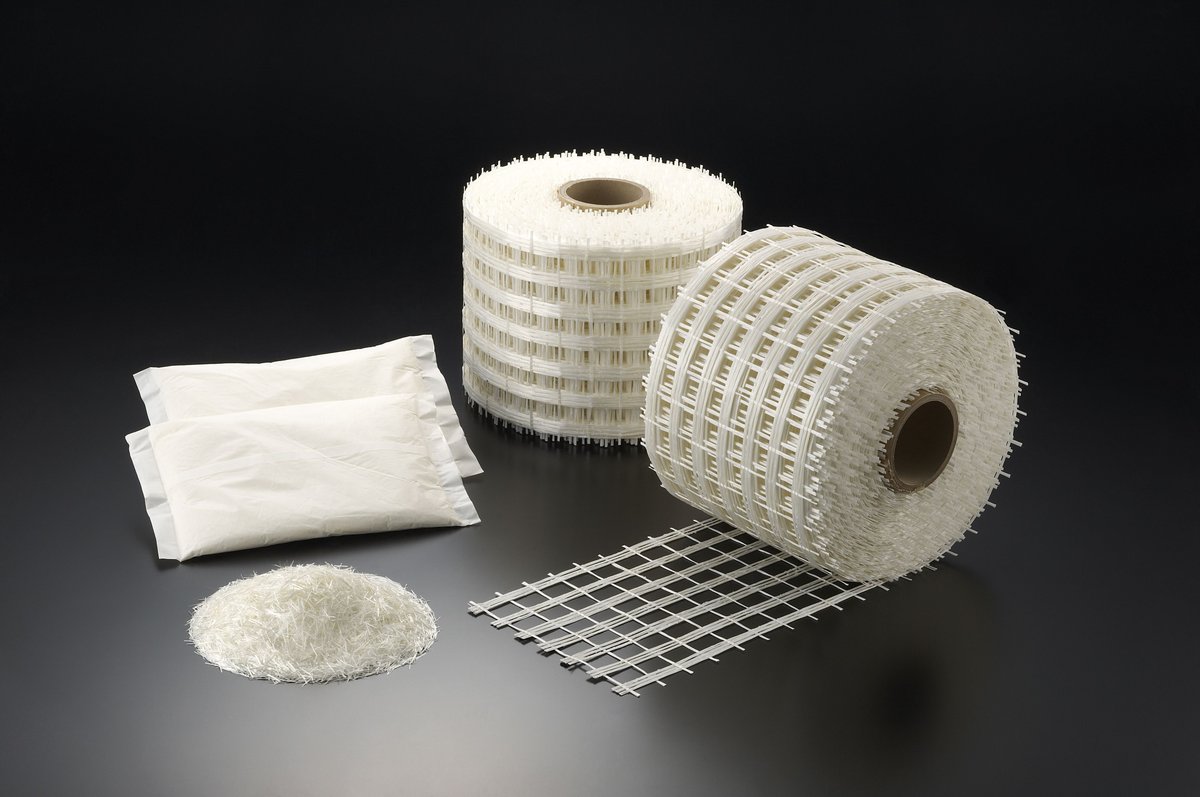

Glass fibers which reinforce and reduce the weight of concrete and highly functional resins

Regarding glass fibers, our E glass fibers, which are characterized by outstanding electrical insulation performance, are used for vehicles, electronic devices, and household equipment as reinforcing materials for highly functional resins and other plastics. Meanwhile, WizARG™, which is resistant to alkali, is used in many fields of construction and civil engineering as a reinforcing material for concrete products.

E-fibers, which contribute to cost reduction of vehicles

Vehicles are the most typical application of E-fibers. Previously, vehicles were made up of many metal parts. Today, components, parts, and materials using lightweight resins have been increasingly modularized in response to the growing demand to streamline production processes and improve fuel efficiency, safety, and environmental performance. The strength of resins is comparable to that of metals because glass fibers are used as reinforcing materials.

Because resins enable efficient production of components of complex shapes, they are used for interior components, such as ceiling materials and door modules, as well as various parts and materials in the engine bay. Thus, resins contribute to improving fuel efficiency and reducing costs by streamlining production processes.

With vehicles being rapidly electrified, the use of components, parts, and materials reinforced by glass fibers is expected to expand into the future.

WizARG™, which can reduce the weight of an entire building

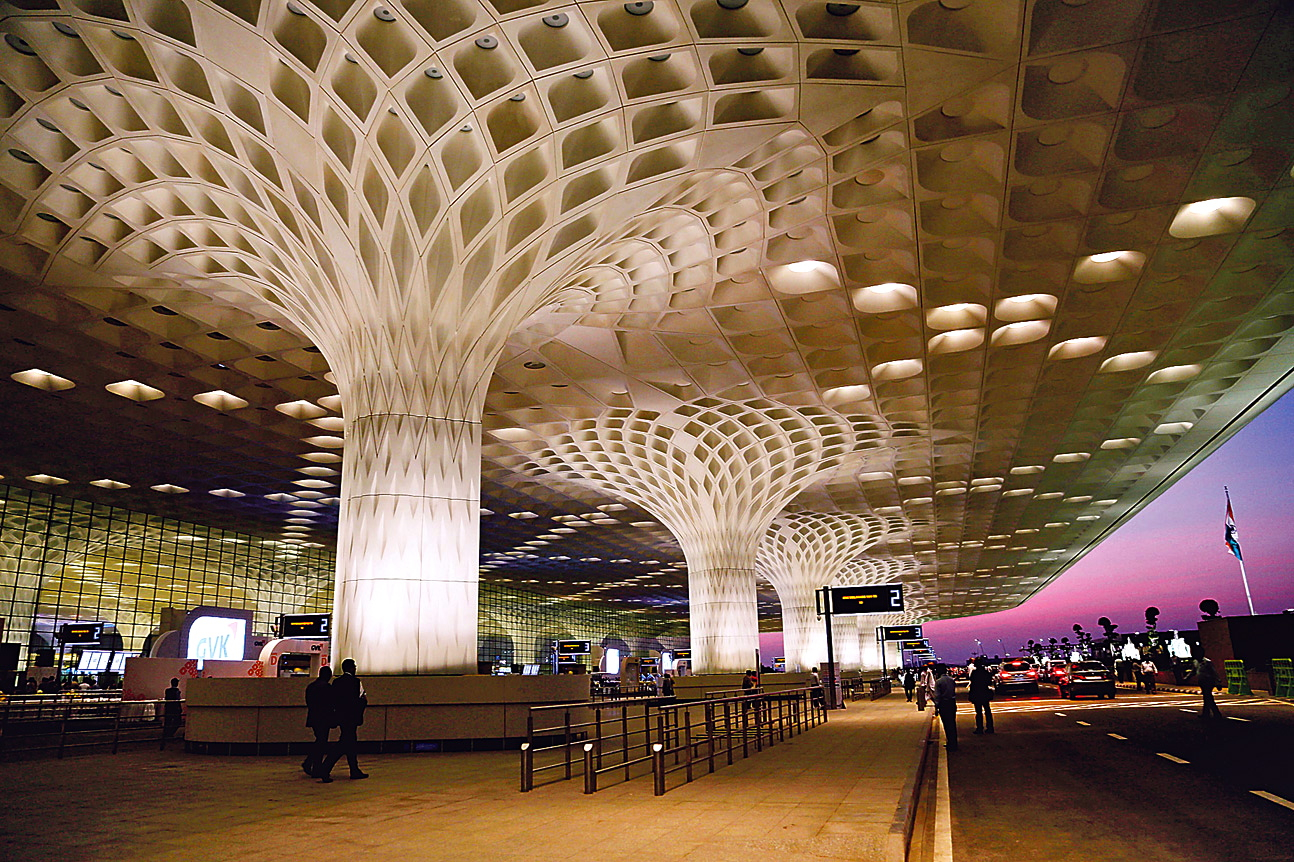

WizARG™ glass fibers are resistant to acids and alkalis and are used as reinforcing materials for concrete products. Unlike concrete products reinforced with steel bars, those reinforced with glass fibers do not pose any concerns regarding corrosion. Because the glass fibers are distributed evenly throughout the entire part or material for reinforcement, the thickness of parts and materials can be reduced significantly, leading to a reduction in the weight of an entire building.

Glass fiber-reinforced concrete (GRC) reinforced with WizARG™ enables easy installation through production and modularization at plants using forms, including those with complex designs. Realization of strong, lightweight, and flexible designs expands the possibilities of buildings.

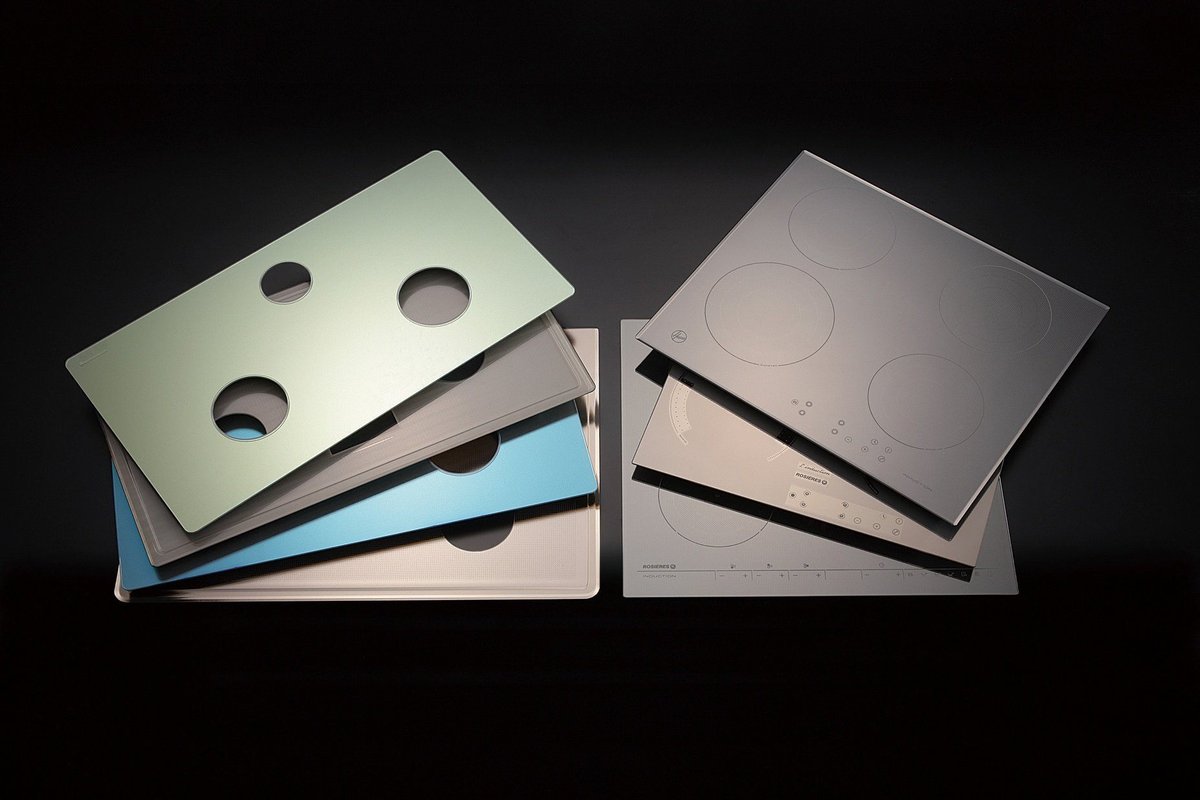

Glass-ceramics, which are used in our daily lives

NEG’s products meet household needs. For example, have you ever poured boiling water into a glass and caused it to break? NEG’s super heat-resistant glass-ceramics change the conventional wisdom that glass is susceptible to rapid temperature changes. This special glass is so resistant to rapid heating and cooling that it does not break even if it is heated over an open flame and then exposed to water.

For example, NEG’s super heat-resistant glass-ceramics are used for familiar items, such as top plates for induction cooking heaters and gas cookers and front doors for wood stoves and fireplaces, as well as fire-rated glass to prevent the spread of fire.

— A market share of over 60% in Japan! The top plate of the cooker in your kitchen may have been manufactured by NEG.—

StellaShine™ is used for the top plates of induction cooking heaters and gas cookers. It has a market share of over 60%* in Japan. This glass has excellent thermal shock resistance. It does not break even if it is exposed to chilled water immediately after being heated to 800°C. It is also resistant to repeated heating. It is eco-friendly glass free from environmentally harmful substances.

* Market share of glass top plates used for built-in cookers in Japan in 2023, based on our survey

ZERØ™ glass, whose coefficient of thermal expansion is zero, that is, it does not expand or contract in response to the ambient temperature changes, is used in the fields of optical communication and electronic devices where extremely high precision and dimensional stability are required. Its applications are expected to expand to the aerospace field.

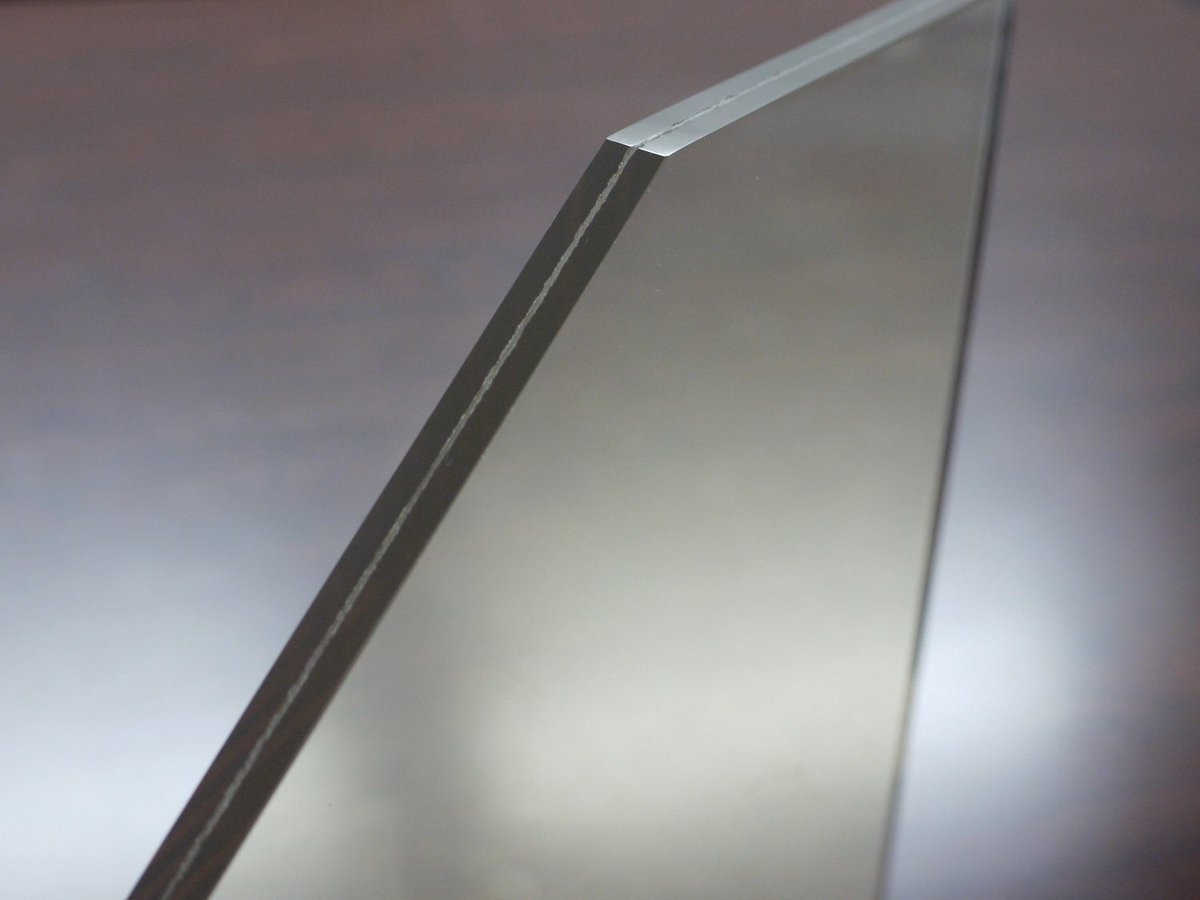

FireLite™, safe and secure glass essential for disaster prevention

NEG’s FireLite™ heat-resistant glass-ceramics protect us from fire. It is strong enough to withstand intense heat in the event of fire and rapid cooling caused by water spraying during firefighting activities. The clear view without wire mesh is another advantage. It also conforms to the UL standards (product safety standards) of the U.S., which are more rigorous than the standards in Japan. Its performance is outstanding.

FireLite Plus™ Neo is manufactured by sandwiching a special resin between two panes of FireLite™. In addition to the outstanding thermal shock resistance of FireLite™, FireLite Plus™ Neo also ensures impact safety, eliminating almost all concerns about the scattering and falling of glass fragments when damaged due to strikes by people or objects or the impact of earthquakes. This is the only fire-rated glass that ensures both heat resistance and impact safety. The glass is ideal for schools where students are physically active, as well as train stations and public facilities where many people gather.

Glass for medical care, which supports people’s health

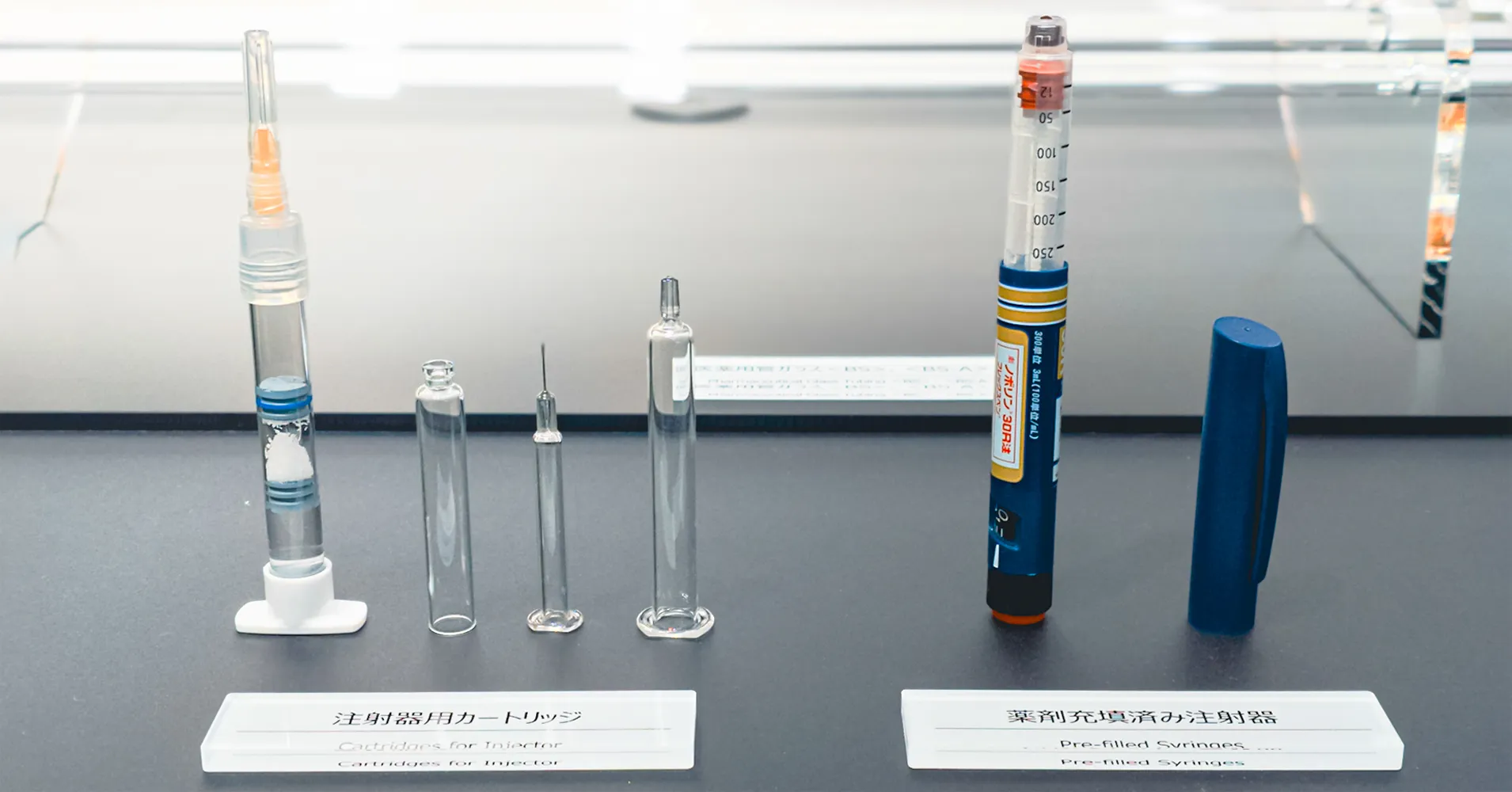

Special glass is also indispensable for hospitals and clinics. NEG supplies glass tubing for pharmaceutical and medical use, which is used for ampoules, vials, and syringes, and radiation-shielding glass, which protects medical workers from radiation exposure, thereby contributing to the advancement and higher safety of medical care.

The future of special glass envisioned by NEG?!

This article showcased only a portion of the fascinating world of special glass. NEG has constantly delivered special glass which meets the needs of the times to the global market. We will continue to pursue the “unlimited possibilities” of glass to support the future of society and people.