Development of Low-loss LTCC Materials for 5G Communication —The challenge of attaining a low loss tangent and thereby achieving low loss —

Through the continuous development of LTCC*1 materials with a low loss tangent *2, which are suitable for parts and devices used for 5G communication, Nippon Electric Glass Co., Ltd. (Head Office: Otsu, Shiga, Japan, President: Motoharu Matsumoto) has succeeded in dramatically improving the characteristics of its product lineup, which was commercialized in 2020, and attaining the highest characteristics in the industry.

5G is a communication technology that enables high-speed, large-capacity, low-delay communication and multiple simultaneous connection. High frequencies of 28 to 40GHz, which are known as millimeter waves, are used for this communication. Various LTCC substrates are used in parts and devices that process the signals (e.g., circuit boards, filters). For these parts and devices, the higher the frequency and the greater the loss tangent, the greater the signal attenuation. Thus, to realize more efficient communication in millimeter waves, it is necessary to suppress signal attenuation and attain low signal loss by using LTCC substrates made from materials with a low loss tangent.

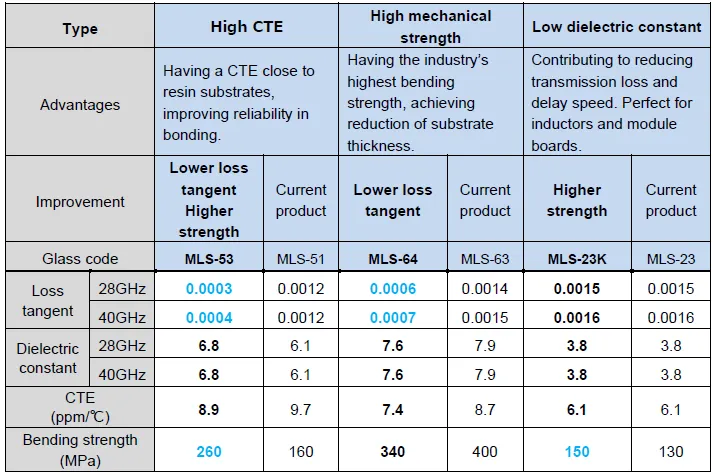

The company has solved issues in the market for three types of LTCC materials (high CTE, high mechanical strength, and low dielectric constant), which were developed and commercialized last year and characterized by a low loss tangent. For the high CTE type in particular, the loss tangent has significantly exceeded the target of 0.0010 or less. A low loss tangent of 0.0003, the lowest in the industry and 75% lower than the current product, has been achieved. For the high mechanical strength type, the characteristics have been improved to attain a loss tangent of 0.0006, which is 57% lower than the current product. For the low dielectric constant type, the strength, which posed an issue toward commercialization, has been improved by about 15% from 130 MPa to 150 MPa. This is the highest strength in the industry as a material with a dielectric constant of less than four. The characteristics and improvements of each product are shown in the table below.

The company plans to exhibit these products at the Total Solution Exhibition for Electronic Equipment “JPCA Show 2021” to be held at Tokyo Big Sight from October 27 to October 29, 2021.

The company is manufacturing and selling special glass products for various electronic devices. With these products, the company will furtherly respond to new market needs and contribute to improve the performance of next-generation communication equipment.

-

LTCC: Low Temperature Co-fired Ceramics. This is a composite material of glass powder and ceramic powder, and can be fired at low temperatures of 1000°C or less. By co-firing this material and a silver conductor with high electric conductivity to create a multilayer structure, complex high-frequency components can be manufactured.

-

Loss tangent: a measure of energy when dielectrics are polarized. The smaller the loss tangent, the lower the conversion of electromagnetic energy into heat, and as a result attenuation of signals is reduced.

■Characteristics and improvements of the new products

■Products and applications