Nippon Electric Glass, a Pioneer in Oxy-fuel Combustion, Begins Offering Carbon-Neutral Glass Manufacturing Technology to the Glass Industry

Promoting carbon neutrality throughout the glass industry

with its engineering business

Nippon Electric Glass Co., Ltd. (Head Office: Otsu, Shiga, Japan; President: Akira Kishimoto;) has launched an engineering business to provide carbon-neutral technology for use in glass manufacturing as a new development toward achieving its Medium-Term Business Plan EGP2028.

Business Overview

In this engineering business, Nippon Electric Glass will provide technologies to reduce CO2 emissions during glass manufacturing as part of utilization of its intellectual property related to glass manufacturing that it has fostered over many years.

Oxy-fuel combustion is a typical example of CO2 emissions reduction technology. It is a groundbreaking technology that the Company introduced early on, ahead of the rest of the industry. Currently, over 95% of the combustion facilities for melting furnaces used within the Company's group are of the oxy-fuel combustion type, making the Company outstanding as the owner of the most advanced technology in the industry.

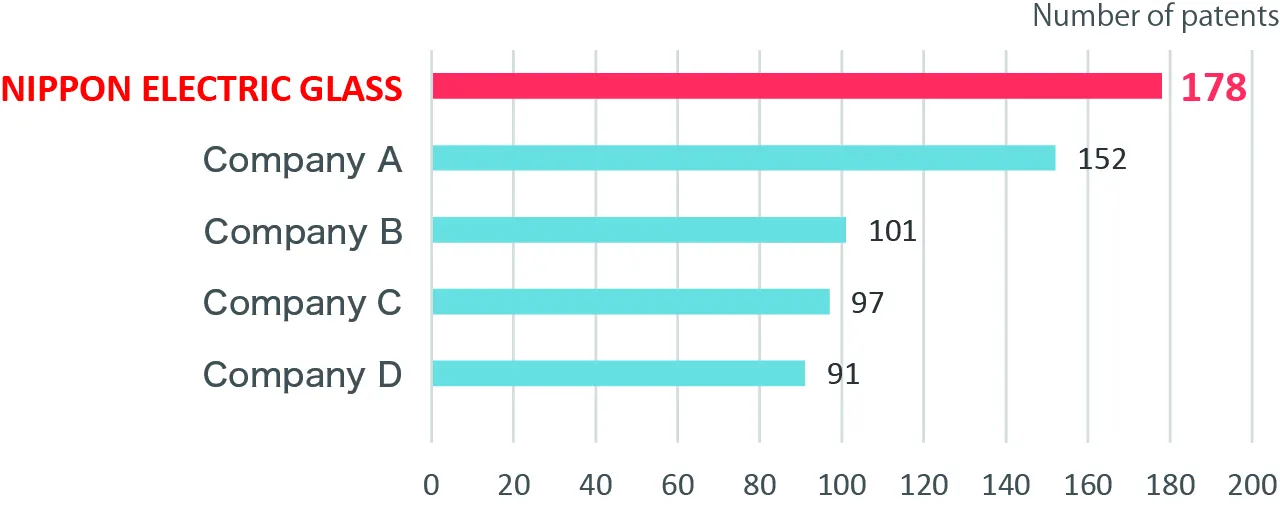

Additionally, the Company has filed the most patent applications related to glass melting in the past 10 years. It has excellent intellectual property, including non-patented know-how. The Company has accumulated industry-leading technologies toward carbon-neutral glass manufacturing.

-

International Patent Classification C03B5/00 (Melting in furnaces; Furnaces so far as specially adapted for glass manufacture). Application dates: 2014 to 2024

-

June 24, 2024

-

Patsnap Analytics (developed by Patsnap Pte. Ltd.)

Examples of technologies that promote carbon neutrality

NEG Oxy-fuel Combustion (NOFC) Technology

In 1993, the Company was the first in Japan to successfully introduce oxy-fuel combustion technology to a glass melting furnace. Today it is used in the combustion equipment of almost all of the Company's furnaces. Because oxy-fuel furnaces do not introduce nitrogen into the furnace, the amount of waste heat from exhaust gases significantly decreases, reducing fuel consumption and CO2 emissions. In addition, it also eliminates the need for a heat regenerator in an air combustion furnace, which saves resources and reduces waste. The Company has over 30 years of experience and know-how in melting furnaces of various sizes used with various glass materials.

Its NOFC is also compatible with hydrogen-oxygen combustion. It is possible to perform oxy-fuel combustion of gases made by mixing hydrogen with current natural gas in any ratio, which will enable further reductions in CO2 emissions depending on the development status of the hydrogen infrastructure.

NEG Electric Melting Technology (NEMT)

In 1960, the Company first introduced direct electric heating technology into a glass melting furnace. The technology of heating molten glass by passing electricity directly through it is a revolutionary technology with high heat transfer efficiency and no gas emissions from combustion. However, the electrodes inserted into the molten glass require advanced peripheral technologies. Utilizing the technology it has fostered through more than 60 years of experience, the Company has now implemented direct electric heating in most of its melting furnaces. Moreover, by developing an all-electric melting furnace that does not use combustion at all, the Company has achieved high glass quality and production efficiency. In the future, it will be possible to achieve carbon neutrality by switching the electricity we use to renewable energy sources.

NEG Furnace Control System (NFCS)

The Company has developed a highly efficient and reliable glass melting furnace control system that achieves optimal heating conditions for a variety of glass materials. Optimal control of heating provided by combustion and electricity improves glass quality, and the intuitive user interface contributes to the safe and stable operation of the glass melting furnace. Additionally, options such as various systems for monitoring furnace operation status and CFD (fluid analysis) simulations are available to help build a highly efficient glass melting process. Provision of optimal solutions for reducing energy consumption and CO2 emissions will promote the achievement of carbon neutrality.

Comments from senior vice president Kanaya (in charge of Process Development & Engineering)

“In recent years, growing awareness of environmental issues has led to calls for carbon neutrality in the manufacturing industry. In order to achieve carbon neutrality in glass manufacturing, we have developed our proprietary oxy-fuel combustion technology, hydrogen-oxygen combustion technology, electric melting technology, and melting furnace control systems, and have been developing and evaluating glass melting furnaces that use these technologies.

I believe that these technologies can be applied for carbon neutrality not only within the Company but throughout the entire glass industry. Through this business, we will be able to utilize the technology we have cultivated—boasting the world's largest number of patent applications for glass melting technology—widely across the glass industry, thereby contributing to reducing the environmental impact of the entire industry and to achieving the sales targets set out in our Medium-Term Business Plan EGP2028.”

【About Nippon Electric Glass】

Nippon Electric Glass Co., Ltd. is a world-class specialty glass manufacturer headquartered in Otsu City, Shiga Prefecture. Special glass that creates novel functionality is transformed into a variety of products such as sheets, tubes, threads, and powder, and is used in a wide range of fields, including semiconductors, displays, automobiles, electronic devices, medical care, and energy. The special glass developed using the technology and track record that we have honed over our 70-year history is highly regarded in a wide range of fields, from everyday life to cutting-edge industry.

Company name: Nippon Electric Glass Co., Ltd.

Representative: Akira Kishimoto, President

Head office location: 7-1 Seiran 2-chome, Otsu, Shiga 520-8639, Japan

Founded: December 1, 1949

Business details: Manufacture and sale of special glass products and fabrication and sale of glass manufacturing machinery

URL: https://www.neg.co.jp/en/

Nippon Electric Glass Co., Ltd. 7-1 Seiran 2-chome, Otsu, Shiga 520-8639, Japan

(Inquiries about our releases)

PR Office, Administrative Division Phone: +81-77-537-1702

(Inquiries about our business and services)

Process Development & Engineering Group Contact Us