Development of a Key Component for Laser Fusion

The Glass Faraday Element: A Crucial Innovation for Large High-Power Lasers

Nippon Electric Glass Co., Ltd. (Head Office: Otsu, Shiga, Japan; President: Akira Kishimoto), Institute of Laser Engineering at Osaka University, National Institute of Fusion Science, and Kyoto University have developed "Glass Faraday Element" as key component of large high-power lasers. The optical isolator incorporating this component suppresses laser back reflection, a major issue in large high-power lasers. High-power lasers are expected to be applied in a variety of fields that require precision engineering and advanced laser control, such as laser fusion, the removal of space debris, and cancer therapy using heavy particle beams.

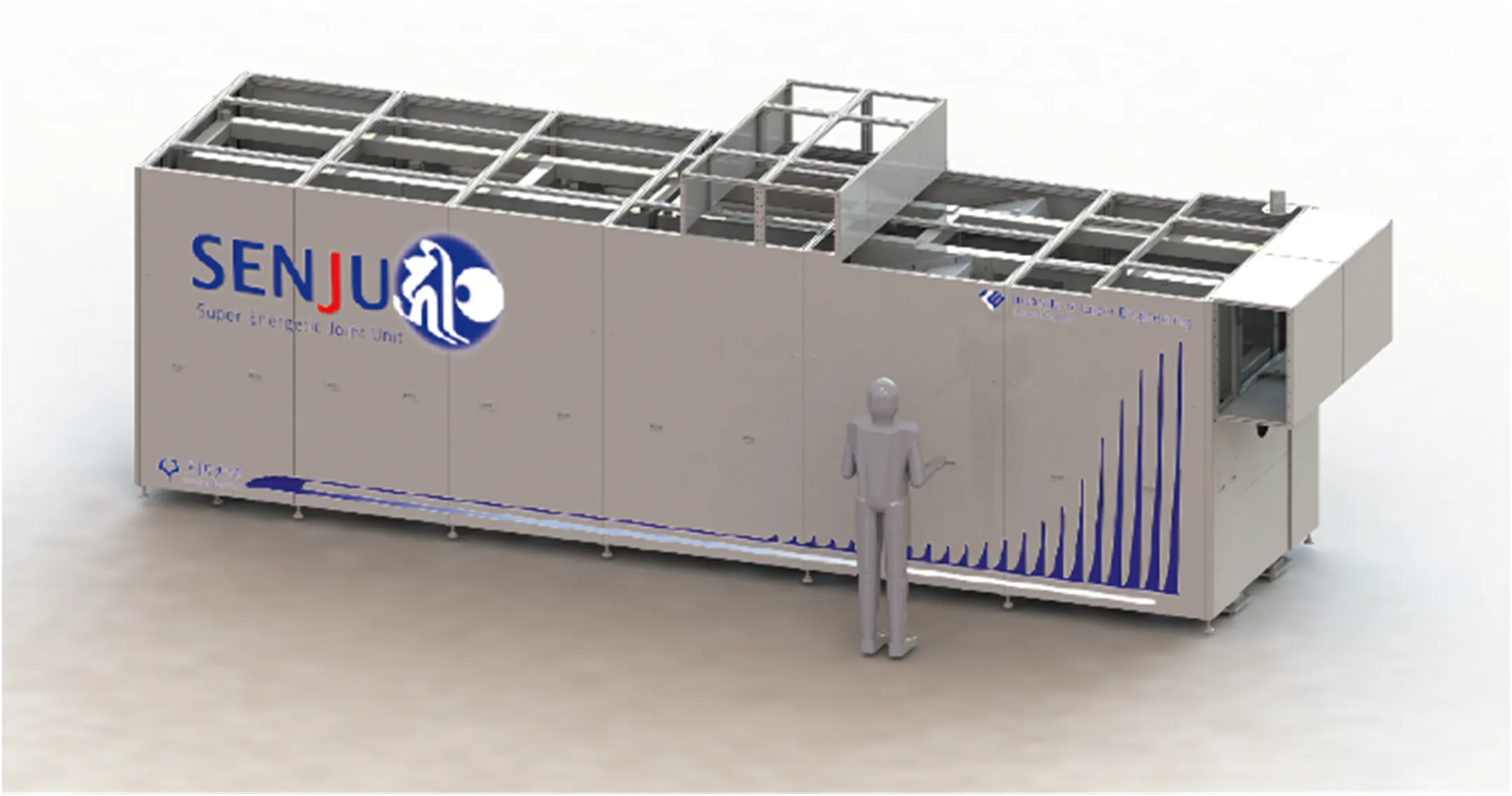

Institute of Laser Engineering at Osaka University is currently developing a large-scale high-power laser system called SENJU, which features a large beam diameter of Φ90mm. As a key component for controlling the beam, Glass Faraday Element that can be made large in size are considered promising.

Features of Glass Faraday Element

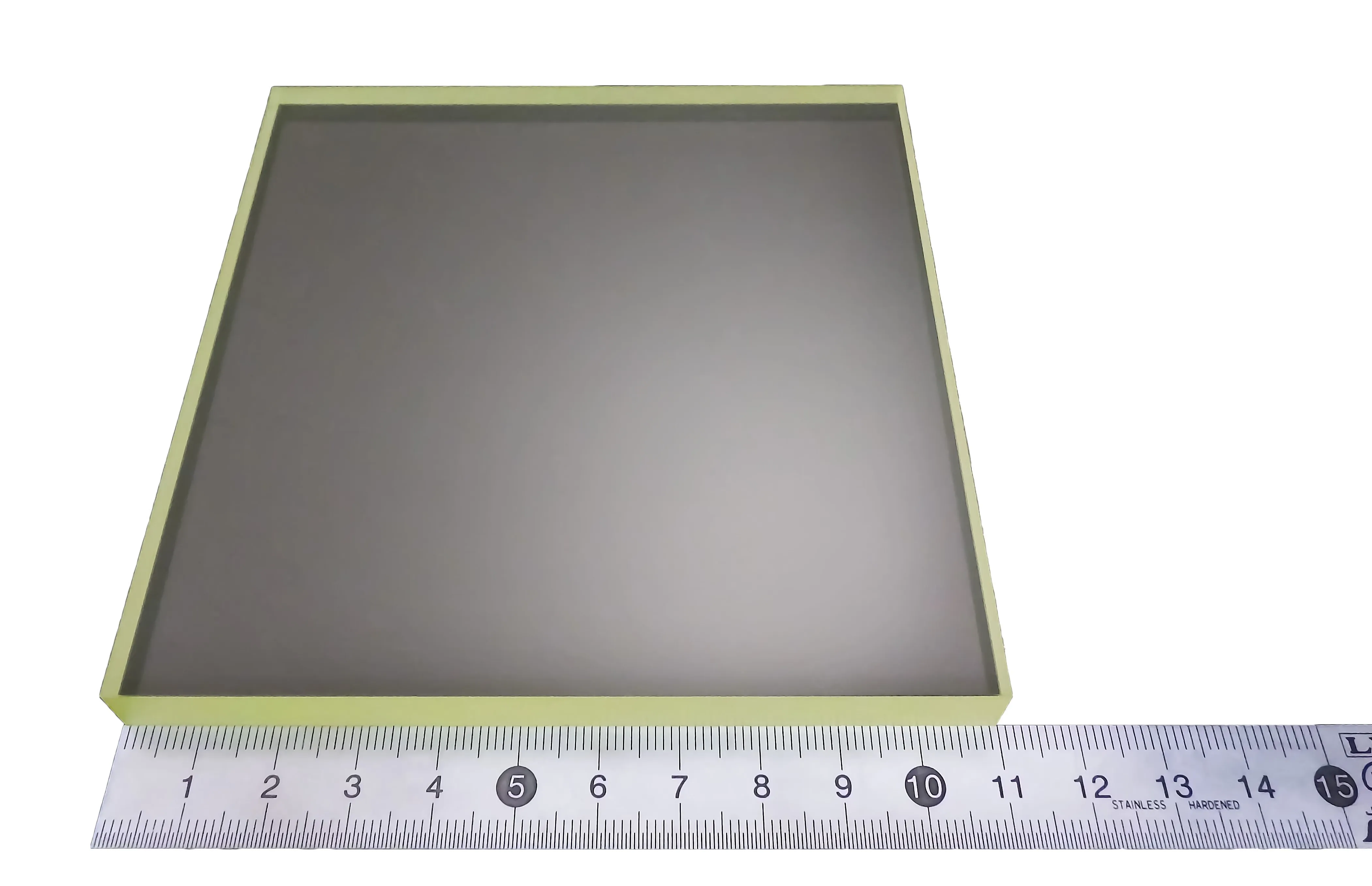

The Glass Faraday Element is an optical component used in optical isolators. It is a specialized element that rotates the polarization plane of light by utilizing a magnetic field. The newly developed glass-made Faraday device has the following features, surpassing conventional materials such as terbium gallium garnet (TGG).

-

Can be manufactured in larger sizes

It is 110✕110mm enough to control very large diameter beams (Φ90mm).

-

High-power resistance

With a lower absorption coefficient than TGG, it maintains optical quality even under high-power laser operation.

|

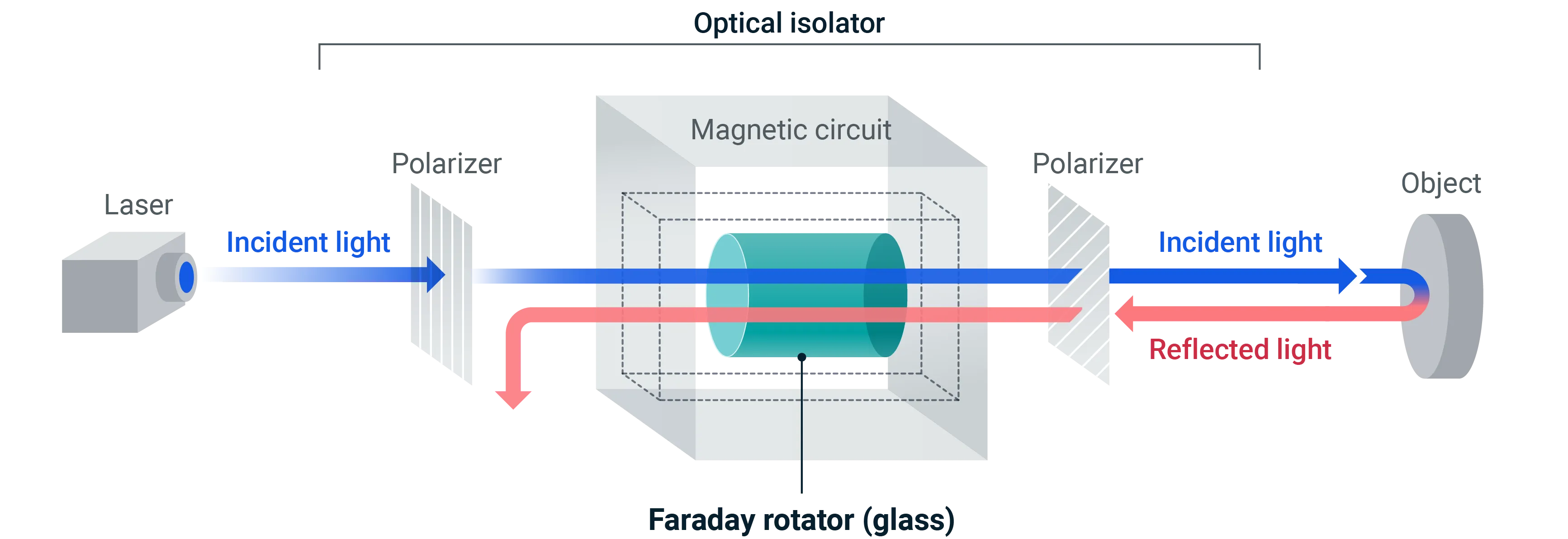

Faraday element |

One of the parts that control light, which uses the force of a magnet to rotate the angle of the polarization plane of light. |

|

Optical isolator |

In laser systems, it is essential to suppress unwanted reflected light. An optical isolator is an indispensable device for laser equipment to prevent damage to the light source and generation of noise because it passes forward light and blocks backward light. |

|

Absorption coefficient |

A parameter that quantifies how much light a material absorbs. Absorbing laser light generates birefringence (a phenomenon in which light is refracted in two different directions when it passes through a specific substance). It lowers the degree of polarization and leads to a decrease in the quality of the beam. |

|

TGG |

TGG (terbium gallium garnet) is a special crystalline material widely used in optical applications. Laser power resistance is high, but it is difficult to increase the size. |

|

Laser Fusion |

A technology that uses intense laser light to cause a fusion reaction. Nuclear fusion is a phenomenon in which a large amount of energy is released in the process in which light nuclei (usually isotopes such as deuterium and tritium) are bonded to form heavier nuclei. |

|

SENJU |

Abbreviation for high-power laser equipment, Super-Energetic Joint Unit, which is being developed by Institute of Laser Engineering at Osaka University and aims to achieve the world's highest mean power. Conventional high-power lasers can fire lasers only once every few hours due to cooling-related technical issues, but SENJU is capable of firing 100 laser pulses per second by devising materials and cooling methods. |

|

High power laser |

Advanced combined light technology used in laser fusion, removal of space debris, and advanced medicine such as cancerous therapy with heavy particle beams. |

Background of joint development

Laser back reflection from high-power lasers poses a major challenge for the realization of the equipment, as it poses a risk of laser equipment damage and noise problems. Nippon Electric Glass has developed a glass-made Faraday element that meets the requirements for large, high-power lasers by leveraging its experience in developing compact optical isolators for high-power lasers. Kyoto University and the National Institute of Fusion Science are evaluating the glass. The Institute of Laser Engineering at Osaka University is implementing it as an optical isolator for the "SENJU"

The Future of Laser Fusion and Energy Security

Laser fusion is attracting attention as a next-generation energy source with the aim of providing a stable energy supply and realizing carbon neutrality. With an energy self-sufficiency rate in Japan of approximately 13% (as of FY2021) *, laser fusion offers great potential for energy security.

*Source: PR pamphlet "Japan's Energy 2023" published by Agency for National Resources and Energy, Ministry of Economy, Trade and Industry

Future prospects

We will continue prototyping glass with suitable size and thickness for laser fusion, while evaluating its optical properties and performance. We are advancing toward the commercialization of an optical isolator incorporating the Glass Faraday Element.

The development of glass-made Faraday elements can be applied not only to large high-power lasers, but also to a variety of high-performance products related to optical systems, such as optical communications and spectrometers. We will continue to develop products to solve customer problems and contribute to the realization of a sustainable society.

Notice of exhibition participation

The Glass Faraday Element and Nippon Electric Glass's optical isolators for high-power lasers will be exhibited at OPIE'25 to be held in Pacifico Yokohama from April 23 and LASER World of PHOTONICS 2025 to be held in Munich, Germany from June 24.

|

Name of exhibition |

OPIE'25 |

LASER World of PHOTONICS 2025 |

|

Dates |

April 23 (Wednesday)-April 25 (Friday), 2025 |

From Tuesday, June 24 to Friday, June 27, 2025 |

|

Venue |

Pacifico Yokohama, Japan |

Munich, Germany |

|

Booth |

P-31 |

- |

Glass faraday devices, Optical isolator products page

Related Release

Successful Development of the World’s Smallest Optical Isolator for High Power Fiber Lasers, Using Magneto-Optical Glass (October 22, 2018)

https://www.neg.co.jp/en/news/news_20181022.html

[Nippon Electric Glass Co., Ltd]

Nippon Electric Glass Co., Ltd. is a world-class specialty glass manufacturer headquartered in Otsu City, Shiga Prefecture. Special glass that creates novel functionality is transformed into a variety of products, such as sheets, tubes, fibers, and powder, and is used in a wide range of fields, including semiconductors, displays, automobiles, electronic devices, medical care, and energy. The special glass developed using the technology and track record that we have honed over our 70-year history is highly regarded in a wide range of fields, from everyday life to cutting-edge industry.

-

Nippon Electric Glass Co., Ltd.

-

Akira Kishimoto, President

-

7-1 Seiran 2-chome, Otsu, Shiga 520-8639, Japan

-

December 1, 1949

-

Manufacture and sale of special glass products and fabrication

[Institute of Laser Engineering, Osaka University]

The Institute of Laser Engineering at Osaka University has been a global leader in laser technology development and applications since its predecessor, the Laser Engineering Research Facility, was established within the Faculty of Engineering at Osaka University in 1972. Above all, laser fusion research is an interdisciplinary academic field that explores the potential of fusion energy as the ultimate energy source for humanity, generating various spin-off technologies. In addition, we have a high international presence and excellence as a research institute that leads the world in laser science, such as pioneering new disciplinary fields of fusion in our original fields such as laser astrophysics and plasma photonics. In addition, we develop and utilize one of the world’s largest power lasers. Based on internationally high expectations as the world’s largest laser facility operated for 100% academic use, we are contributing to the creation of new academia and the realization of industrial innovation as a base for joint use and research.

[National Institute for Fusion Science]

The National Institute for Fusion Science conducts research in various fields essential for realizing practical fusion energy, including plasma physics, micro-quantum processes, materials science, and engineering technologies for fusion-related equipment. As a university cooperative institution, we provide a wide range of research facilities, including large-scale helical devices (LHD), supercomputers, and other large-scale research facilities, for joint use, and promote joint research with universities and research institutions both domestically and overseas, thereby promoting the development of fusion science and the formation of a foundation for science and technology.

[Laboratory for Laser-Matter Interaction Science, Institute for Chemical Research, Kyoto University]

The Laboratory for Laser-Matter Interaction Science at the Institute for Chemical Research (Tokita Laboratory), Kyoto University, focuses on research in high-intensity laser science, including the generation, control, and application of high-power laser light. Specifically, our research focuses on developing high-power lasers, including mid-infrared systems, and investigating laser-plasma interactions, contributing to advancements in next-generation optical science and technology.

[Department of Material Chemistry, Industrial Solid-State Chemistry, Graduate School of Engineering, Kyoto University]

The Industrial Solid-State Chemistry Laboratory in the Department of Material Chemistry, Graduate School of Engineering, Kyoto University, conducts research on the electronic properties of inorganic solids, with a particular focus on metal oxides. Until now, we have synthesized oxide solids with complex structures in terms of the magnetic and magneto-optical effects of metastable oxides containing amorphous oxides, dielectric properties and magnetism of oxides in which charge order and spin order coexist and have clarified the electronic properties and the mechanism by which they appear. In recent years, we have been working to elucidate the basic electrical conduction mechanism of wide-band-gap oxide semiconductors and to apply them to devices such as Schottky barrier diodes and metal-semiconductor field-effect transistors.