ARG Fiber WizARG™: Roving

Glass fiber with a highly resistant to alkali and acid

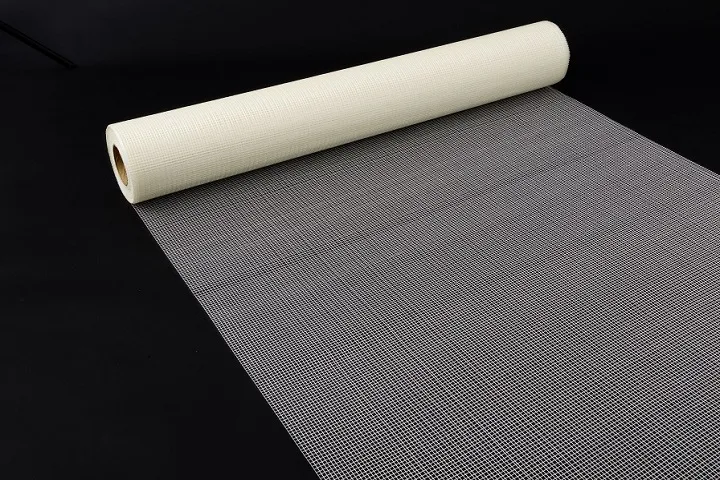

This product is made up of numerous strands, each consisting of 100 to 200 glass filaments (monofilaments) bundled together and wound into a cylindrical shape. It is used in hand-spraying methods and mass production molding equipment for manufacturing glass fiber reinforced concrete (GRC). Ideal for shaping large exterior wall panels and flat surfaces, it is widely used in the construction and civil engineering industries.

Applications

-

GRC (wall panels, flooring, permanent formwork)

-

Pulling, Weaving, FW

Product List

| Grades | Process | Recommended Application | Specification | Data Sheet | ||||

|---|---|---|---|---|---|---|---|---|

| Hand Spray | Premix | Textile Production | GRC | Mortar Render | Concrete | Tex | ||

| 2500H-103 | ● | ● | ● | 2500 | H-103 | |||

| 3100H-103 | ● | ● | ● | 3100 | ||||

| 5000H-103 | ● | ● | ● | 5000 | ||||

| 2500H-200 | ● | ● | ● | 2500 | H-200 | |||

| 2500H-350Y | ● | ● | ● | 2500 | H-350Y | |||

| 5000H-350Y | ● | ● | ● | 5000 | ||||

| 5000H-530X | ● | ● | ● | ● | 5000 | H-530X | ||

| 3000H-960 | ● | ● | ● | 3000 | H-960 | |||

| 320S-920 | ● | ● | ● | ● | 320 | S-920 | ||

| 640S-920 | ● | ● | ● | ● | 640 | |||

| 1200S-920 | ● | ● | ● | ● | 1200 | |||

| 1100S-830 | ● | ● | ● | ● | 1100 | S-830 | ||

| 2400S-830 | ● | ● | ● | ● | 2400 | |||

Related Links

Need More Details? Connect with Us!

Related Products

Find Similar Products

Functions and Characteristics

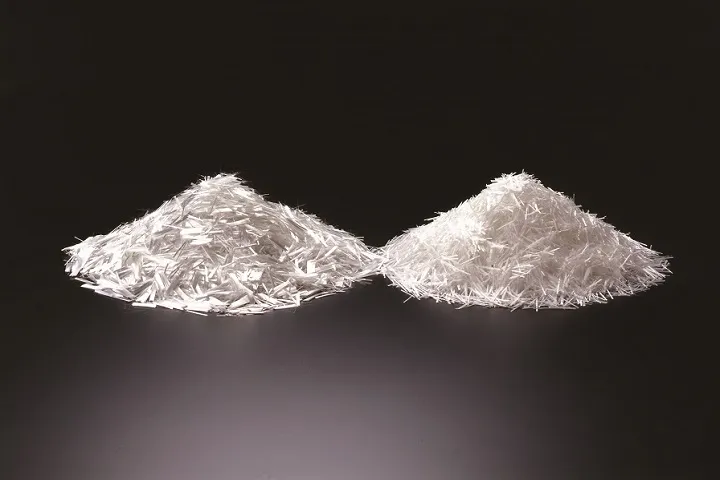

Shape