Communicating with Stakeholders

Communicating with Customers

We not only establish a quality assurance system to provide our customers with safe and reliable products, but we also share product information when necessary to ensure that our customers have access to all the information they need.

Product Safety and Quality Assurance

The principle of “customer first” is a key value in our corporate philosophy, and our commitment to achieving the highest level of customer satisfaction is one of our essential management policies. We have established fundamental policies for product safety and quality assurance, which aim to enhance customer satisfaction and ensure the delivery of safe, reliable, and high-quality products.

Product Safety Basic Policy

We are committed to providing safe products that consumers can use with confidence.

-

Strongly prioritizing product safety from the design stage

-

Continuously improving product safety through quality assurance

-

Actively working to reduce risks throughout the product life cycle

-

Promptly disclosing information and ensuring product safety in the event of an accident involving our product

Quality Assurance Basic Policy

Under the principle of “customer first,” we provide products that meet customer satisfaction through the collaboration of all divisions involved in sales, manufacturing, and development.

-

Thoroughly understanding customer needs and consistently reflecting these needs in product specifications

-

Marketing products that adhere to appropriate quality assurance standards

-

Continuously improving product quality and enhancing manufacturing processes to ensure high standards

-

Taking prompt and appropriate action to address any issues reported by customers

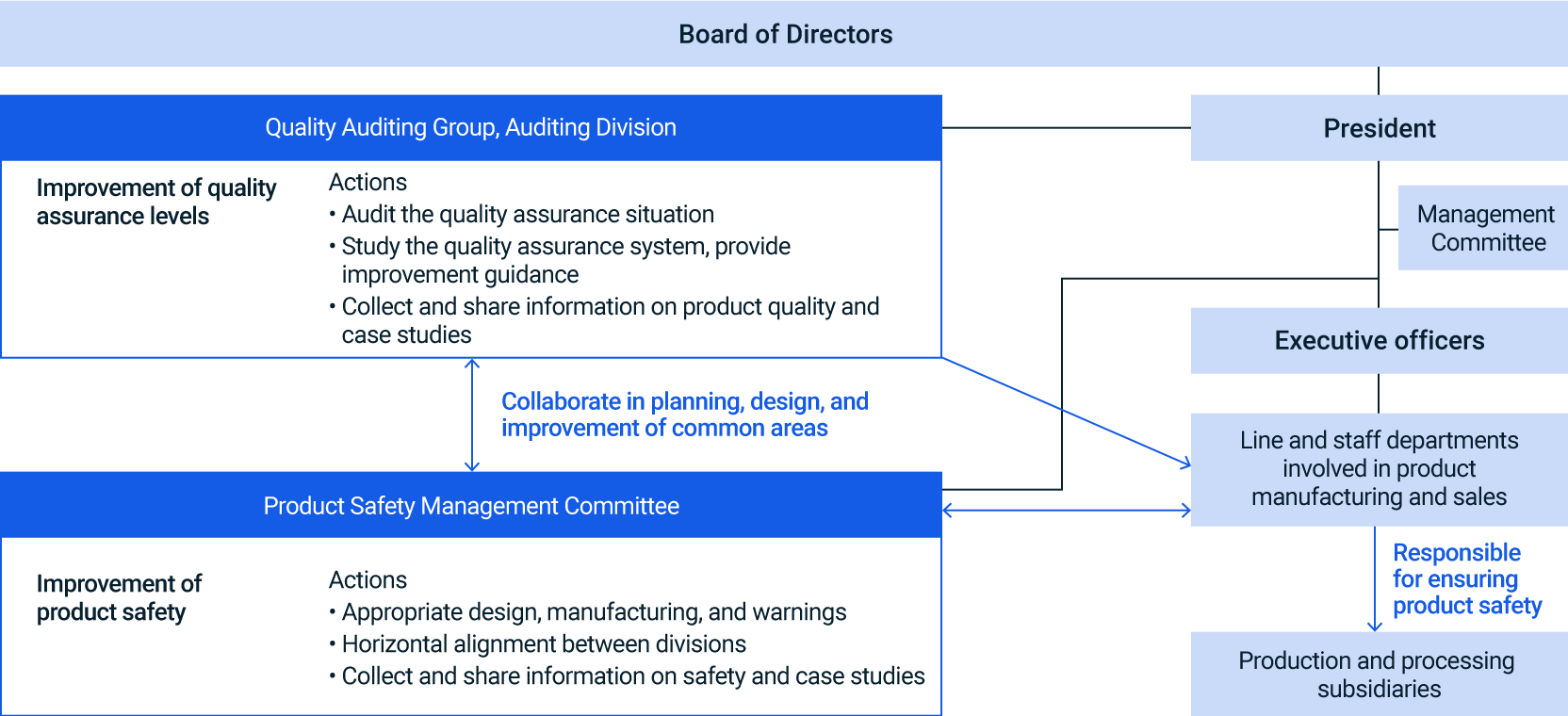

Product safety and quality assurance system

Product safety management committee

The Product Safety Management Committee is dedicated to enhancing the safety of our products. Committee members are chosen from line departments responsible for manufacturing and sales, as well as from staff departments involved in product design and process design. The main focus of the group includes the following tasks:

-

Appropriate design, manufacturing, and warnings

-

Horizontal alignment between divisions

-

Collect and share information on safety and case studies

Quality assurance department

Each of our line departments involved in product manufacturing includes a quality assurance department. Our personnel are responsible for quality assurance for each product, addressing customer requests and contributing to the improvement of manufacturing expertise.

Quality auditing group, auditing division

We have established a Quality Auditing Group within the Auditing Division, which operates under the direct control of the president. This group leads cross-company initiatives to enhance quality assurance levels throughout the entire NEG Group. The main focus of the group includes the following tasks:

-

Audit quality assurance

-

Study the quality assurance system, provide improvement guidance

-

Improvement guidance

Communicating Product Information

We use exhibitions and our website as communication tools to introduce our products and provide relevant information.

Communicating with Business Partners

We engage with our business partners by sharing our insights and collaborating to deliver better products and services while fostering a sustainable supply chain.

Basic Procurement Policy

In line with our established basic procurement policy, we aim to build reliable relationships with business partners who can provide a stable supply of high-quality products and services at competitive prices. To enhance the performance and efficiency of the entire supply chain, we require our business partners to adhere to our supply chain guidelines, ensure a stable supply, improve their competitiveness, comply with laws and regulations, respect human rights, and protect the environment.

We recognize that minerals such as tin, tantalum, tungsten, and gold sourced from the Democratic Republic of the Congo and neighboring countries can be used to finance armed groups engaged in inhumane acts. Therefore, we place great importance on responsible procurement practices to ensure that we do not source conflict minerals.

Basic Procurement Policy

-

Open and fair business practices

-

Mutual prosperity with partners

-

Compliance with social norms

-

Respect for human rights

-

Environmental awareness

-

Policies on conflict minerals

Business Partner Briefings

We conduct regular business partner briefings to enhance communication with our partners.

| FY2024 | |

|---|---|

| Number of companies attending the business partner briefing | 156 |

Requests for Our Business Partners

-

Maintain and improve product competitiveness and ensure a stable supply

-

Comply with laws, regulations, and social norms; respect human rights; and consider working conditions

-

Prioritize environmental preservation

-

Manage information appropriately

-

Practice sound corporate management

-

Eliminate the use of conflict minerals

Supplier Surveys

To promote understanding of our supply chain guidelines and green procurement policies, as well as to enhance the effectiveness of our supply chain initiatives, we conduct an annual survey of our major suppliers to seek their commitment to supporting and participating in NEG initiatives. Additionally, we visit key suppliers to assess their efforts in environmental conservation, health and safety, and other related areas.

| FY2024 | |

|---|---|

| Number of participating companies in the supplier survey | 116 |

Announcement of the Partnership Building Declaration

In March 2022, we announced the Partnership Building Declaration, signaling our commitment to establishing new partnerships through cooperation and mutual prosperity with the companies in our supply chain that help us create value.

Communicating with Shareholders and Investors

View relevant information for shareholders and investors about our company and engage in constructive dialogue

Information Disclosure Policy

We utilize the Tokyo Stock Exchange’s Timely Disclosure Network (TDnet) and promptly post information on our website to ensure compliance with the disclosure rules it establishes.

Additionally, we actively use news releases and web pages to present information that we believe will help our stakeholders gain a better understanding of our Group. This is done in a timely, appropriate, and fair manner, in accordance with Japan’s Fair Disclosure Rules.

General Meeting of Shareholders

The 106th General Meeting of Shareholders was held on March 28, 2025. After presenting the fiscal year results and the current state of our business, our management openly addressed the issues raised by our shareholders.

Communicating with Investors

We engage with institutional investors both in Japan and abroad through various channels, including individual interviews, financial results briefing sessions, and investor events organized by securities firms. The feedback and requests we receive from investors are communicated to our management and used to enhance our investor relations activities.

| Companies in Japan | 107 | |||||||||||

| Overseas companies | 126 | |||||||||||

| Total number of dialogues | 233 | |||||||||||

| Of which ESG was the main topic | 15 | |||||||||||

Main topics of dialogue

Key discussion points include business strategies to enhance profitability, financial strategies to improve capital efficiency, sustainability strategies, the growth potential of the electronic device business (especially for semiconductors), shareholder return policies, and the expansion of information disclosure.

Status of feedback for management

The content of our dialogues with shareholders and investors is regularly reported to the Management Committee.

Actions taken in response to dialogue

-

Expand information disclosure, including medium-term management plan status and analysis of operating income change

-

Scope 3 emissions calculations