Water Reduction

Basic Policy

Our main business bases are located near Lake Biwa, which has long influenced our deep respect for water as a vital resource. Recognizing the fundamental importance of water to our business, in 2003 we introduced the Water Business Plan for effective and efficient use of water. We view water usage not only as an environmental concern but also as an indicator of our manufacturing sophistication. Our water management efforts help us better understand and optimize the glass melting, forming, and processing operations, leading to continuous technological and facility improvements.

Rising demand for water worldwide, driven by population growth and economic development, has made access to abundant and sustainable high-quality water an increasingly important management issue at our overseas sites. In response, we have implemented site-specific water management measures at all overseas sites.

Because water conditions vary by location, we utilize the Aqueduct Water Risk Atlas from the World Resources Institute (WRI) to identify high-risk areas. Based on these assessments, we take targeted actions to secure water supply and reduce water consumption.

Water Classification

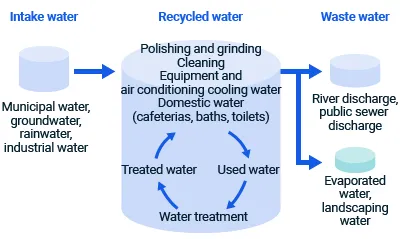

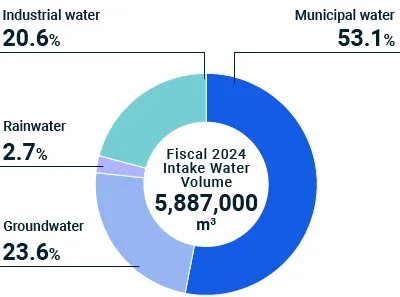

We classify water usage into three categories: intake water (water brought into the company), wastewater (water discharged), and recycled water (water reused within the company). We monitor each classification using key indicators, such as total water intake, wastewater volume, and their respective intensities. In fiscal 2024, our water recycling efforts remained highly effective, with recycled water accounting for 98% of our total water usage.

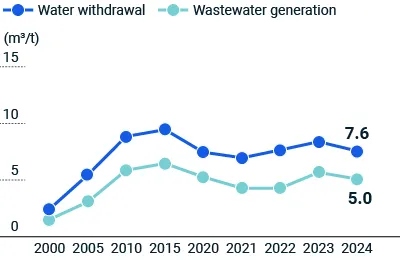

Intake and Wastewater Volume Per Unit of Sales

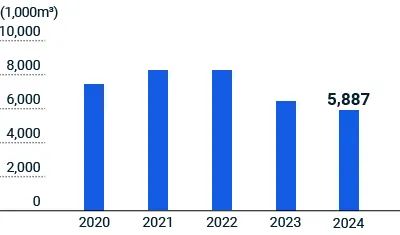

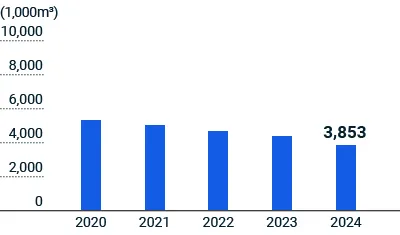

Each year, we formulate site-specific water reduction plans based on local water conditions and reduction efforts. To ensure continued efficient water use, we monitor changes in both intake water and wastewater volume per unit of sales by weight, using the metric of cubic meters per ton of product sold (m³/ton).

Management’s commitment to enhancing water use efficiency has led to a steady decline in water intensity within our displays business since 2014. This follows a successful reversal of the rise in water intensity that occurred during the transition from CRTs to LCDs in 2004.

In fiscal 2024, the water intake per unit of sales by weight across all business divisions in Japan and overseas was 7.6 m³/ton, successfully achieving the target of 7.8 m³/ton. The amount of wastewater discharged per unit of sales was also within the target, reaching 5.0 m³/ton against the planned value of 5.1 m³/ton. We set fiscal 2025 targets to reduce overall water intake to 7.4 m³/ton and wastewater discharge to 4.5 m³/ton. The progress will be regularly reported to and deliberated by the Environmental Management Committee.

To sustainably use valuable water resources, we actively promote the reuse of water in high-volume stages, such as cooling during melting and forming, as well as cleaning during processing. Additionally, we are minimizing water intake and wastewater generation for other applications by implementing cascading strategies tailored to the specific purposes and quality requirements of water use, alongside recycling water through purification methods.