ESG Data

View the performance data on our ESG initiatives.

Environment

External Certification of Environmental Management System

ISO 14001: 2015 Certification Status (As of February 2026)

| Company name | Date of certification | |

|---|---|---|

| Head office | Nippon Electric Glass Co., Ltd. (multi-certification at four plants) | 1999.8.27 |

| Group companies in Japan | SGS Engineering Co., Ltd. | 2001.1.19 |

| Nichiden Glass Processing Company, Limited | 2002.11.1 | |

| LTCC Materials Co., Ltd. | 2020.12.25 | |

| Overseas group companies | Techneglas LLC | 2000.1.31 |

| Nippon Electric Glass (Malaysia) Sdn. Bhd. | 2002.1.12 | |

| Nippon Electric Glass Taiwan Co., Ltd. | 2006.9.18 | |

| Paju Electric Glass Co., Ltd. | 2007.8.28 | |

| Electric Glass (Shanghai) Co., Ltd. | 2009.12.21 | |

| Electric Glass (Guangzhou) Co., Ltd. | 2015.11.11 | |

| Electric Glass (Xiamen) Co., Ltd. | 2017.4.17 | |

| Electric Glass (Nanjing) Co., Ltd. | 2018.4.13 | |

Waste Reduction

Internal Classification of Waste

-

Internal Recycling A

Spent polishing agents, glass shards, and other materials useful in-house as recycled raw materials

-

Social Recycling B

Scrap metal, scrap bricks, waste paper, scrap plastic (recycled), and other materials, which have value externally as reusable materials

-

Corporate Recycling C

Scrap plastic (converted to fuel), waste oil, wood scrap, and other materials, which we pay to have recycled outside the company

-

Landfill Waste D

Incombustible materials, incinerated ash, waste refractories, and other materials that we pay to have disposed of in landfills outside the company and not recycled

Percentage of Sales Weight of Normal Waste, Excluding Landfill Waste D

(%)

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Consolidated | 7.6 | 7.2 | 5.6 |

| NEG | 0.07 | 0.01 | 0.01 |

Breakdown of Plastic Emissions in Japan*

(ton)

| Category | FY2022 | FY2023 | FY2024 |

|---|---|---|---|

| Plastic emissions in Japan | 1,465 | 933 | 969 |

| Social Recycling B | 871 | 311 | 299 |

| Corporate Recycling C | 529 | 617 | 670 |

| Landfill Waste D | 65 | 5 | 0 |

-

Values are retroactively adjusted to from fiscal 2022 due to a change in the waste aggregation method effected in fiscal 2024.

Reduction of Water Consumption

Water Withdrawal/Waste Water per Total Weight of Products Sold

(m3/ton)

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Water Withdrawal | 7.7 | 8.4 | 7.6 |

| Waste Water | 4.3 | 5.7 | 5.0 |

Analysis of Environmental Impact (Consolidated)

Input

| Unit | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | ||

|---|---|---|---|---|---|---|---|

| Energy sources used | Total energy | (GWh) | 5,036 | 5,990 | 5,935 | 4,430 | 3,976 |

| Electricity | (GWh) | 2,038 | 2,337 | 2,433 | 2,050 | 1,997 | |

| Fuel | (GWh) | 2,997 | 3,653 | 3,502 | 2,380 | 1,978 | |

| Water | Water withdrawal | (1,000 m3) | 7,447 | 8,268 | 8,267 | 6,457 | 5,887 |

| Municipal water | (1,000 m3) | - | 4,063 | 3,990 | 3,357 | 3,128 | |

| Groundwater | (1,000 m3) | - | 1,734 | 1,810 | 1,549 | 1,390 | |

| Rainwater | (1,000 m3) | - | 135 | 171 | 165 | 157 | |

| Industrial water | (1,000 m3) | - | 2,258 | 2,140 | 1,343 | 1,211 | |

| Others | (1,000 m3) | - | 77 | 156 | 42 | 0 | |

| Recycled water* | (1,000 m3) | - | 217,489 | 326,680 | 282,553 | 255,852 |

-

Fiscal 2021 and fiscal 2022 amounts do not include certain subsidiaries.

Output

| Unit | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | ||

|---|---|---|---|---|---|---|---|

| Atmosphere | CO₂ | (1,000 tons) | 1,713 | 1,881 | 1,797 | 1,395 | 1,328 |

| Scope1 | (1,000 tons) | 734 | 871 | 790 | 543 | 466 | |

| Scope2 | (1,000 tons) | 978 | 1,010 | 1,008 | 852 | 862 | |

| SOx | (ton) | 149 | 96 | 133 | 109 | 71 | |

| NOx | (ton) | 2,694 | 2,524 | 2,506 | 1,508 | 1,541 | |

| Particulate matter | (ton) | 212 | 216 | 242 | 205 | 183 | |

| Water | Waste water | (1,000 m3) | 5,315 | 5,034 | 4,651 | 4,366 | 3,853 |

| Waste | Total amount generated | (1,000 tons) | 120 | 150 | 141 | 112 | 97 |

| Internal Recycling A | (1,000 tons) | 22 | 31 | 33 | 25 | 21 | |

| Total emissions | (1,000 tons) | 98 | 118 | 109 | 87 | 76 | |

| Social Recycling B | (1,000 tons) | 9 | 13 | 13 | 12 | 14 | |

| Corporate Recycling C | (1,000 tons) | 32 | 28 | 22 | 16 | 16 | |

| Landfill Waste D | (1,000 tons) | 57 | 77 | 73 | 59 | 46 |

Notes:

-

The values for SOx, NOx, and particulate matter have been adjusted for fiscal 2022 to fiscal 2023 after reflecting revised coefficients from local authorities.

-

The values for water withdrawal in fiscal 2022 have been revised as a result of changes in the coverage area of the data.

Environmental Accounting (NEG)

Environmental Conservation Costs

(Million yen)

| Category | Main activities | FY2023 | FY2024 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Investment | Expenses | Investment | Expenses | |||||||

| (1) Costs within operational area | Costs to reduce environmental footprint of production activities within operational area | 5,921 | 3,159 | 3,382 | 2,200 | |||||

| Breakdown | 1. Anti-pollution maintenance and management cost | 24 | 719 | 12 | 548 | |||||

| 2. Global environmental conservation costs | 5,873 | 791 | 3,127 | 181 | ||||||

| 3. Resource recycling costs | 24 | 1,649 | 243 | 1,471 | ||||||

| (2) Upstream and downstream costs | Costs to reduce environmental footprint of upstream and downstream production activities | Costs for green procurement, product recycling, container and packaging recycling, environmental conservation measures | - | 479 | - | 376 | ||||

| (3) Costs of management activities | Environmental conservation costs within management activities | Costs for environmental education, ISO 14001 system construction and maintenance, and measuring of environmental footprint; labor costs of environmental managers | 31 | 707 | 14 | 742 | ||||

| (4) Research and development Costs | Environmental conservation costs of R&D activities | Expenses related to the development of environmentally friendly products, expenses related to production technology designed to reduce environmental impact | 331 | 546 | 178 | 889 | ||||

| (5) Costs for social initiatives | Environmental conservation costs of social initiatives | Beautification and tree-planting activities for harmonious coexistence with local communities, support for local communities, environment-related advertising costs, afforestation | - | 93 | - | 94 | ||||

| (6) Environmental remediation costs | Costs to deal with damage to the environment | Environmental restoration expenses | - | 4 | - | 5 | ||||

| (7) Other costs | Other costs relating to environmental conservation | Expenses for dismantling and removal of environment-related equipment and facilities | - | 106 | 29 | 27 | ||||

| Total | 6,283 | 5,094 | 3,603 | 4,333 | ||||||

-

Of investment and expenses, only those amounts clearly related to environmental concerns have been aggregated. In regard to production facilities and R&D, only sections related to the environment have been included.

Investment Amount

(Million yen)

| Category | Main activities | FY2023 | FY2024 |

|---|---|---|---|

| Total investment | Scheduled repair of glass melting furnaces and production rationalization investment, investment to improve manufacturing productivity of major products | 34,087 | 25,209 |

| Total research and development costs | Development and improvement of process technology, and development of products, including glass for displays and glass for electronic devices | 7,703 | 7,556 |

| Sales Amount of Valuable Materials Related to “Environmental Conservation Costs” (1) 3. | Sales of scrap metal, scrap bricks, etc. | 127 | 70 |

| Sales Amount of Valuable Materials Related to “Environmental Conservation Costs” (2) | 0 | 0 |

Third-party Assurance Statement (Scope 1 and 2)

Social

Hiring a Diverse Workforce

Employment of People with Disabilities

Percentage of Employees with Disabilities (NEG and consolidated subsidiaries in Japan)

(%)

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| NEG | 4.2 | 4.3 | 4.3 | 4.1 | 3.9 |

| Statutory employment rate in Japan | 2.2 | 2.3 | 2.3 | 2.3 | 2.5 |

| National average | 2.2 | 2.2 | 2.3 | 2.3 | 2.4 |

Hiring Mid-Career Professionals

Career Recruitment

| Unit | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|---|

| Percentage of mid-career hires | (%) | 15 | 39 | 52 | 32 | 46 |

| Number of mid-career hires | (Persons) | 24 | 24 | 44 | 29 | 53 |

| New graduate hires | (Persons) | 47 | 37 | 41 | 80 | 63 |

Human Resource Development

Education and Training Held (Fiscal 2024; NEG)

| Unit | FY2024 | |

|---|---|---|

| Training hours (under head office education section) | (Hours/Person) | 49 |

| Training cost (company-wide) | (Million yen) | 329 |

| Per person | (Thousands of yen/Person) | 189 |

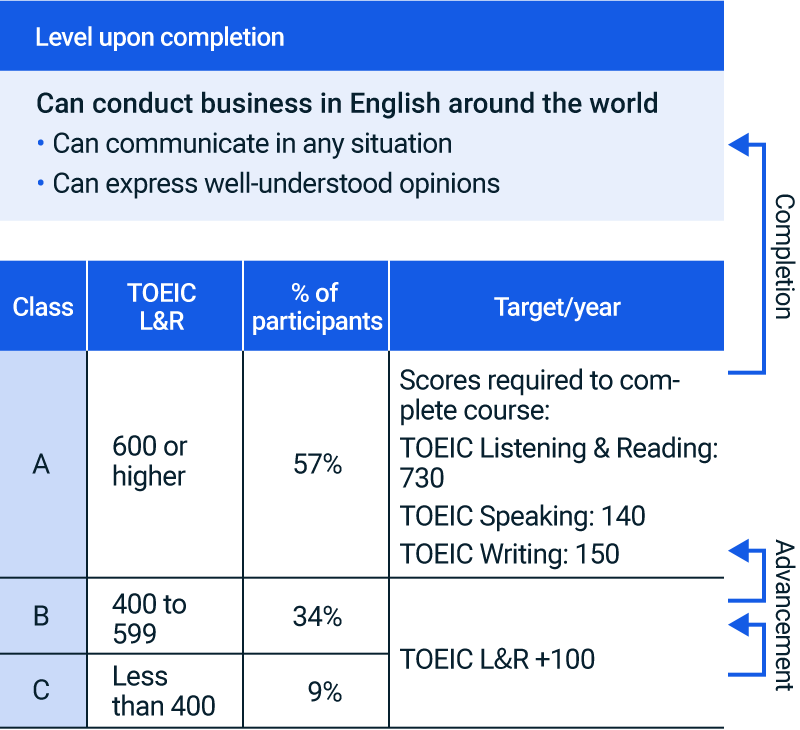

Global Communications Program (GCP) Number of Participants

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|---|

| 107 | 119 | 125 | 162 | 151 |

Global Communications Program (GCP)

Goals and Completion Levels

Efforts to Retain and Empower Employees

Progress in Diverse Work Styles and Work Efficiency

Number/Percentage of Paid Leave Days Taken

| Unit | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|---|

| Percentage of days taken | (%) | 68 | 66 | 75 | 78 | 78 |

| Days taken | (Days) | 16.3 | 15.9 | 18.0 | 18.8 | 18.6 |

-

Paid leave days/year: 24

Average Overtime Work

(Hours)

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Average overtime work per month | 17.2 | 18.4 | 17.4 | 14.4 | 16.7 |

Support for Raising the Next Generation

Childcare Leave Utilization Rate and Percentage of Women Returning to Work (NEG)

(%)

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Utilization rate for women*1and % returning to work*2 | 100 | 100 | 100 | 100 | 100 |

| Average utilization rate for women*4 | 82 | 85 | 80 | 84 | - |

| Utilization rate for men*3 | 20 | 31 | 58 | 86 | 84 |

| Average utilization rate for men* 4 | 13 | 14 | 17 | 30 | - |

-

Utilization rate for women: Number of people taking childcare leave ÷ Number of employees giving birth × 100

-

Percentage returning to work: After giving birth, percentage of people working continuously when child has turned 1 year old

-

Utilization rate for men: Number of men taking childcare leave ÷ Number whose spouses gave birth × 100

-

Source: Statistics on national average childcare leave utilization rate for men and women, taken from Basic Survey of Gender Equality in Employment Management; Ministry of Health, Labour and Welfare

Women’s Empowerment

Trends in Indicators for the Promotion of Women's Activities

(%)

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Percentage of female employees (including workers on loan) | 8.5 | 8.8 | 9.0 | 9.9 | 9.8 |

| Percentage of female managers (including workers on loan) | 1.0 | 1.4 | 1.0 | 1.2 | 1.3 |

| Percentage of new female employees (new graduates in career-track positions) | 15.6 | 20.8 | 33.3 | 25.5 | 28.6 |

-

In 2023, although the percentage of new female employees dropped from the previous year, the number of new female employees rose by 60%.

Number of Employees, Years of Continuous Service, Turnover Rate

| Indicators | Gender | Unit | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|---|---|---|---|

| Number of employees | Men | (Persons) | 1,524 | 1,530 | 1,530 | 1,541 | 1,569 |

| Women | 149 | 152 | 157 | 172 | 177 | ||

| Total | 1,673 | 1,682 | 1,687 | 1,713 | 1,746 | ||

| Average years of service | Men | (Year) | 24.1 | 24.3 | 23.8 | 22.9 | 21.9 |

| Women | 19.7 | 18.8 | 17.8 | 16.2 | 14.6 | ||

| Total | 23.7 | 23.8 | 23.2 | 22.2 | 21.2 | ||

| Turnover rate | - | (%) | 1.6 | 1.2 | 1.3 | 1.9 | 2.0 |

-

Number of employees and average years of service do not include employees on loan.

-

Years of continuous service is on a downward trend because of the increase in male and female new hires.

-

We strive for an environment conducive to a comfortable long-term workplace, and the result has been a low employee turnover rate.

Salary

Male-Female Wage Gap (Female Wage as Percentage of Male Wage)

(%)

| Employee category | Male-female wage gap |

|---|---|

| All employees | 67.2 |

| Regular employees | 68.3 |

| Part-time and fixed-term employees | 38.1 |

Supplement: Male-Female Wage Gap for Regular Employees for Standard Wages Excluding Allowances, Etc.

(%)

| Employee category | Male-female wage gap |

|---|---|

| Managers | 87.8 |

| Career-track | 91.6 |

| Regular employees other than the above | 88.2 |

Period:

-

Fiscal 2024 (January 1 to December 31, 2024)

Wages:

-

Includes compensation for overtime and bonuses, but excludes commuting allowance, etc.

Regular employees:

-

Excludes employees on loan from NEG to other companies, or from other companies to NEG

Part-time and fixed-term employees:

-

Employees who have an employment contract for a fixed period

-

Notes:

-

Although we calculate wages for men and women based on the same standard, male-female wage gaps occur due to differences in things such as number of employees, employment categories, and years of continuous service. Other factors contributing to wage gaps include various allowances for shift work employees (of whom 98% are men) and the fact that there are relatively fewer women in senior management positions.

-

In the employee category of part-time and fixed-term employees, the difference in employment categories is a major reason for wage gaps

Employee Awareness Surveys

Fiscal 2024 Survey Results

| Unit | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|

| Total number of respondents | (Persons) | 1,915 | 1,955 | 1,938 |

| Response rate | (%) | 97.8 | 99.7 | 99.6 |

Occupational Safety and Health; Health and Productivity Management

Industrial Accident Frequency Rate (NEG)

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| All industries in Japan | 2.0 | 2.1 | 2.1 | 2.1 | - |

| Manufacturing industry | 1.2 | 1.3 | 1.3 | 1.3 | - |

| NEG | 0.8 | 0.4 | 0.9 | 0.4 | 0.4 |

Industrial Accident Severity Rate (NEG)

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| All industries in Japan | 0.09 | 0.09 | 0.09 | 0.09 | - |

| Manufacturing industry | 0.07 | 0.06 | 0.08 | 0,08 | - |

| NEG | 0.01 | 0.01 | 0.01 | 0.00 | 0.03 |

Indicators and Targets for Health and Productivity Management (NEG)

| KPIs | FY2024 | FY2026 target |

|---|---|---|

| Rate of presenteeism*1 | 26.7% | Less than 23% |

| Rate of mental health leave*2 | 1.3% | Less than 1% |

-

Presenteeism: When employees go to work but are not fully productive due to some kind of health problem. A higher percentage is worse.

-

Rate of mental health leave: Percentage of employees taking leave due to mental illness.

Governance

Corporate Governance

Total Amount of Directors’ and Corporate Auditors’ Remuneration in Fiscal 2024

| Category | Total amount of remuneration (million yen) | Total amount for each type of remuneration (million yen) | Number of eligible officers | ||

|---|---|---|---|---|---|

| Fixed remuneration | Performance-linked remuneration | Non-monetary remuneration | |||

| Directors (Number of outside directors) |

338 (37) |

242 (37) |

60 (-) |

35 (-) |

9 (4) |

| Corporate auditors (Number of outside corporate auditors) |

60 (14) |

60 (14) |

- (-) |

- (-) |

4 (2) |

|

Total (Number of outside directors) |

398 (51) |

302 (51) |

60 (-) |

35 (-) |

13 (6) |

Number of Stocks and Amount of Strategic Shareholdings Reported on the Balance Sheet

| Unit | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|---|

| No. of stocks | (Stocks) | 31 | 29 | 26 | 23 | 19 |

| Amount | (Million yen) | 43,830 | 40,516 | 35,852 | 38,095 | 37,295 |

Compliance

Number of Whistleblowing Reports and Consultations Received through the NEG Hotline (Consolidated)

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Number of Whistleblowing or Consultations | 11 | 12 | 25 | 16 | 18 |

Compliance Education, Workshops, and Lectures Held in Fiscal 2024

| Region | Name | Intended persons | Times | Participants | Theme |

|---|---|---|---|---|---|

| Japan | Education for new employees (new graduates) | All new employees (new graduates) | 2 | 50 |

|

| E-learning | Executives and employees at NEG and subsidiaries in Japan | - | 2,635 |

|

|

| Lectures | Executives and general managers at NEG, representatives of subsidiaries in Japan, area branch managers | 1 | 57 |

|

|

| Antitrust seminar for sales departments | NEG employees engaged in sales activities | 1 | 125 |

|

|

| Overseas | Workshops | Managers at subsidiaries in China, Taiwan, and South Korea | - | 436 |

|

Number of Infraction Requiring Legal Action (Consolidated)

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Numbers | 0 | 0 | 0 |

Respecting Human Rights

Participation in Training Programs

(Persons)

| Training content | FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|---|

| Cumulative number of employees participating in and dispatched to outside activities (government and external organizations) | 225 | 270 | 126 | 148 |

| Number of employees participating in in-house human rights activities | 807 | 818 | 1,360 | 1,328 |

Communicating with Stakeholders

Number of Participants in Supplier Information Sessions

(Companies)

| Indicator | FY2024 |

|---|---|

| Number of companies attending the business partner briefing | 156 |

Survey of Suppliers

(Companies)

| Indicator | FY2024 |

|---|---|

| Number of companies taking the supplier survey | 116 |

Dialogue with Institutional Investors

(Companies)

| Total number of dialogues | FY2024 |

|---|---|

| Companies in Japan | 107 |

| Overseas companies | 126 |

| Total | 233 |

| Of which ESG was the main topic | 15 |

Related Information

Sustainability

President’s Message

CSR Foundation

Materiality

Environment

Our Approach to Protecting the Environment

Environmental Management

Addressing Climate Change

Waste Reduction

Water Reduction

Biodiversity

Environmentally Friendly Products

Green Loan

Social

Respecting Human Rights

Human Resource Development

Communicating with Stakeholders

Diversity and Inclusion

Better Workplace Environment

Employee Health and Safety

Society and Community

Governance

Corporate Governance

Internal Control

Risk Management

Compliance

External Evaluation

Integrated Report

ESG Data

GRI Index